by alpinac1_pn9him | Aug 19, 2023 | Uncategorized

Six months ago in our last episode of this (seemingly) never-ending restoration, an important and emotionally pleasing milestone was passed: the car was running! The shop that got it started had a punchlist of work I wanted done, mostly road-worthy items (get it running, brakes working right, etc.) and some items that were vexing me, too. Like the heater ducting I couldn’t get installed, hooking up the heater control panel, and installing the finned differential cover.

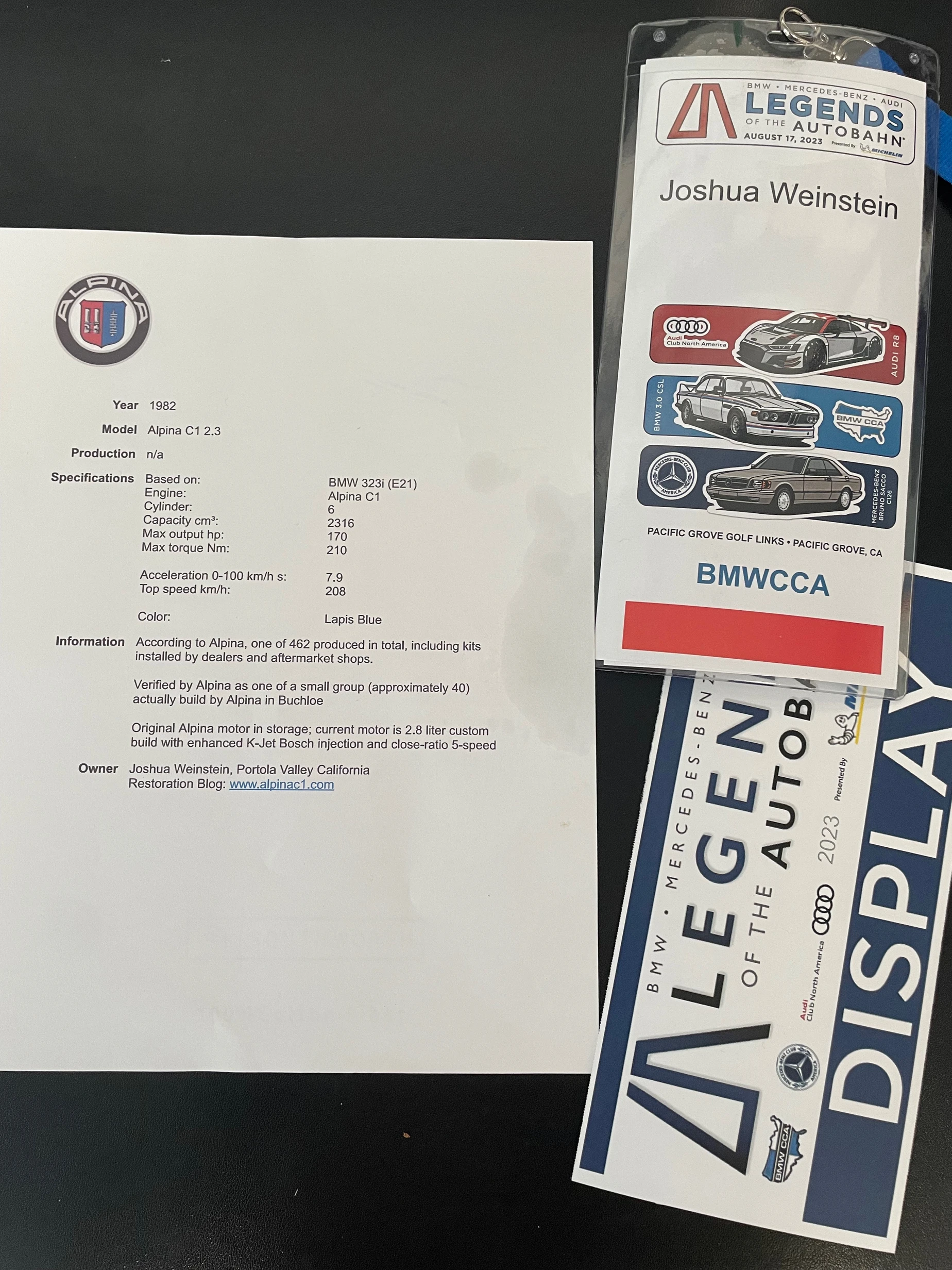

I didn’t like calling them regularly because I didn’t want to be *that* guy and I knew I was lucky to find a competent shop that was willing to work on a vintage car on my time table: getting it ready in time for the 2023 Legends of the Autobahn, part of Monterey’s car week held every August. So, I’d drop by the shop when I was nearby—about once every week or two—just to check on the progress. When I wasn’t stopping by, it was pretty much radio-silence. I could live with that. The three weeks they said they needed to work on the car grew, which wasn’t really unexpected. And that, too, I could live with. We had a good amount of time until August.

Then, one random day I got a call from the body shop that was the next scheduled stop. The car had arrived. I’ll admit I would have preferred to have gotten a heads-up from the mechanics that they were done with the car. And I didn’t love it when I got to the body shop and saw that a few of the punchlist items weren’t done. But most importantly, the car apparently was running well enough and the heater ducting was in, although the control panel wasn’t. You get what you get and, again, I was lucky to find a competent shop that was going to help get it back on the road. Granted it was a drive of all of two blocks from one shop to the other, but I was very excited that the car was (at least semi?) roadworthy!

A punchlist was also provided to the new body shop, The Works in Santa Clara. Top of the list was to color sand the paint thus “finishing” the paint job that started six years ago. (Recall, the car went to my friend’s body shop in Sacramento for paint in 2017 and halfway through the job that body shop closed. I spend much of the early pandemic driving up to Sacramento reassembling the car from the semi-competed painted job.) The Works was hesitant to color sand paint applied by a different shop and there were several areas that they would have done differently; most of their concern was not knowing how thick the paint was and whether they’d burn through to primer while color sanding. But they took the job as long as I understood the risks. Among the more pressing items on the punchlist: installing the heater control panel, the finned differential cover, the rear spoiler and the Alpina stripes (or Deko kit as Alpina calls it).

At this point, I have to apologize: I try to include a lot of images of the progress because as much fun as it is writing (and reading) about the steps taken, pictures are the best was to chronicle the project. But because the car was in other’s folks hands, there are no before and after images of these important milestones. Alas.

When I got a call from The Works to tell me they were almost finished, I stopped by and saw the car. The color sanding was great I think and, even though there were a few spots where they burnt through the paint, they are very small and something only I would worry about. The rear spoiler looked great but at first I was a tad disappointed by the stripes. Not that they didn’t look good, but there was about an inch overlap where they mated the various pieces together. Having never really looked at the stripes closely on my or other Alpinas before, I wondered how the pieces were mated together. (When I got to Legends and saw the other Alpinas there, I realized mine was better than most so the disappointment dissipated.) Also, the heater control panel and finned differential cover were not installed. But, all in all, the progress was amazing and I was very pleased.

Still, I had not driven the car and I was unsure how dialed-in it was. So, I asked if I could take it up and down the block before they finished the few things left and washed it up. Of course they said yes and, although it needed some work—the idle was too low and the steering wheel off kilter—it ran well and seemed like it would make the drive home in a few days. This drive, as short as it was, was the first time in six years that I was behind the wheel in this beast!

The next week, I picked up the car. The idle had been adjusted, the car washed and exterior detailed. I noticed the gas gauge read full and I was impressed the tank had been filled. Once I hit the road I saw the speedometer was not working and the gas gauge bounced between full and empty when the turn signal was on; for the latter, I suspected the fuel sender or turn signal wiring was grounding out. I stopped for gas on the way home and she drank up 12-plus gallons. So much for a reliable gas gauge and full tank!

The last one proved more difficult than anticipated; every time I moved the wheel to the spot that seemed like it would be properly oriented, it needed more adjustment. Time was running out (I left for Monterey the next day at 2pm) when I admitted to myself it needed to get aligned. Luckily, when I called my local shop at 4:45 they squeezed me in after I explained when and where I was going. I dropped the car off and got the call the next day that it was ready at 1:30. They were able to take out a bunch of toe but the caster was slightly off on one side—it will get new control arms soon in hopes of remedying that issue. Nonetheless, the steering wheel was straight and the car tracked almost perfectly. We were off to Monterey….

Driving to Monterey—yes, I know the way!—was joyfully uneventful other than the Bay Area rush hour traffic (which seems to start at 3pm) and the heat. Judging from the slight smell of gas in the cabin, the car was running a bit rich; I had no fuel gauge or speedometer (thank you Waze for telling me my speed); and for the first half of the trip I regretted removing the air conditioning at the beginning of the project so many years ago. Because of the heat in the valley, I took the coastal route (slightly longer but the curvy roads are more fun, too); once over the Santa Cruz Mountains the heat dissipated and my dreams of a/c receded. Oh, and this car is FAST and fun. F. A. S. T.

Once there, the Alpina section at Legends did not disappoint. In addition to mine, there was a Golf yellow 1972 B2 (based on an e9 3.0 CSL), two 6-series B7Ss, three e28 5-series (2 B7 and one B10), a bunch of e36s and even some new(ish) Alpinas. But I’ll let the pictures and videos do the talking below.

Alpina tribute 2002, huge genuine Alpina truck, stunning genuine B2, and our hero:

Our hero and the stunning Golf Yellow genuine 3.0CSL B2 (Alpina truck in the background)

Some of the other Alpinas:

Pics from the Alpina event organizer; yours truly and our hero (right to left):

Collage of all the Alpinas at the event:

The plan is for even more Alpinas at Legends next year. By then I’m hoping to finish up several of the details that haven’t gotten the necessary attention, and maybe even the bigger things, like a working speedo and gas gauge, dialed-in the fuel injection and an operational heater control panel! Who knows, I may even reinstall the air conditioning so I can take the more direct route next year.

by alpinac1_pn9him | Feb 23, 2023 | Uncategorized

The fatigue of this project—and my 1972 Inka touring restomod project—have weighed on me. So much so that the slow but steady progress I was making during the pandemic has almost abated. And, if not for the intervention of others, who knows, it might have died on the vine. But it didn’t and, as alluded in the title of this post, it’s alive; the damn thing runs. Barely.

The car came home in April of 2022, and Spring was full of hope. After all, it was in my garage and instead of having to drive two hours up to Sacramento (and two hours back, of course) I could just saunter the few feet to my garage and tinker. And there was a lot of tinkering to be done.

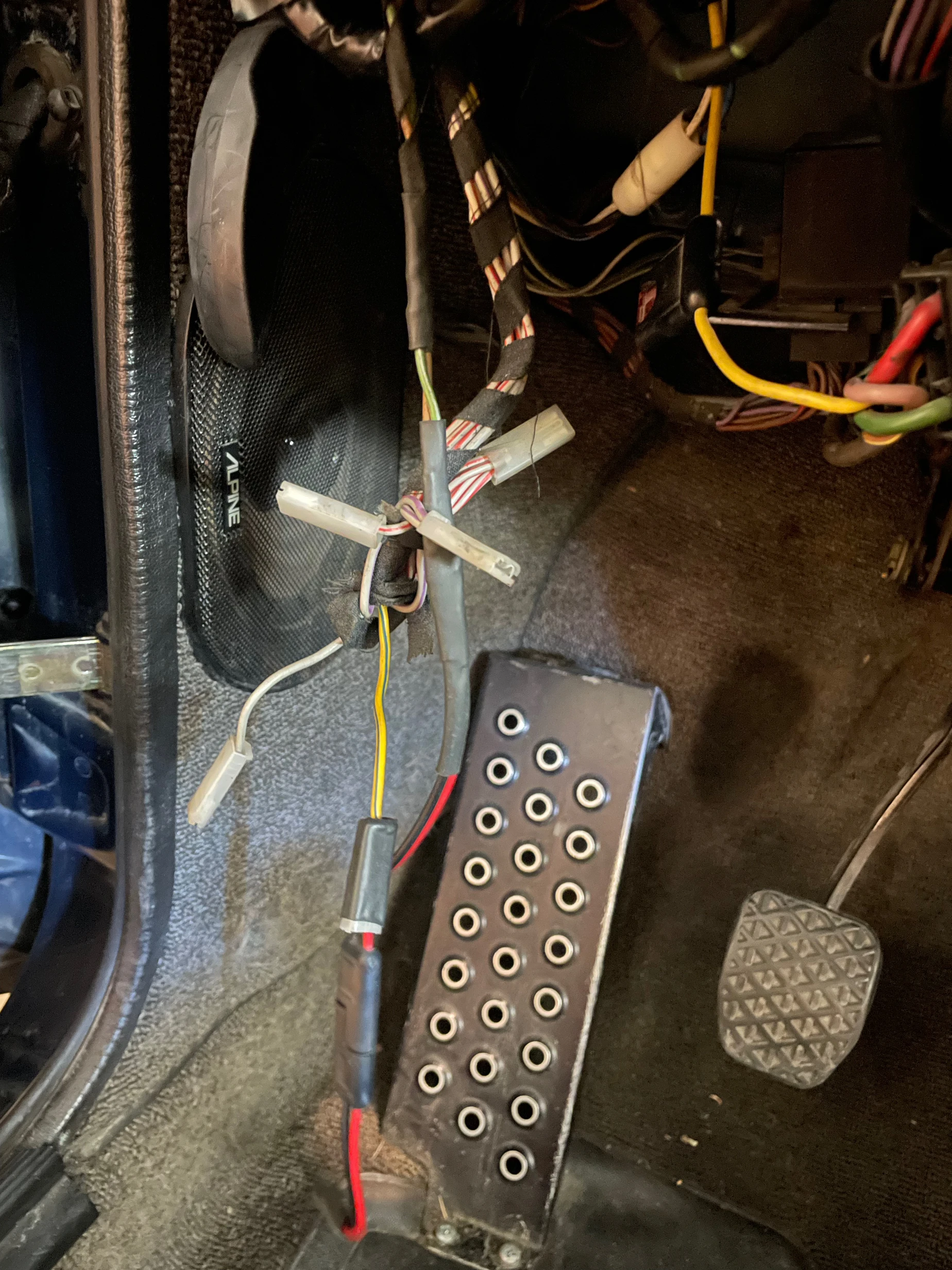

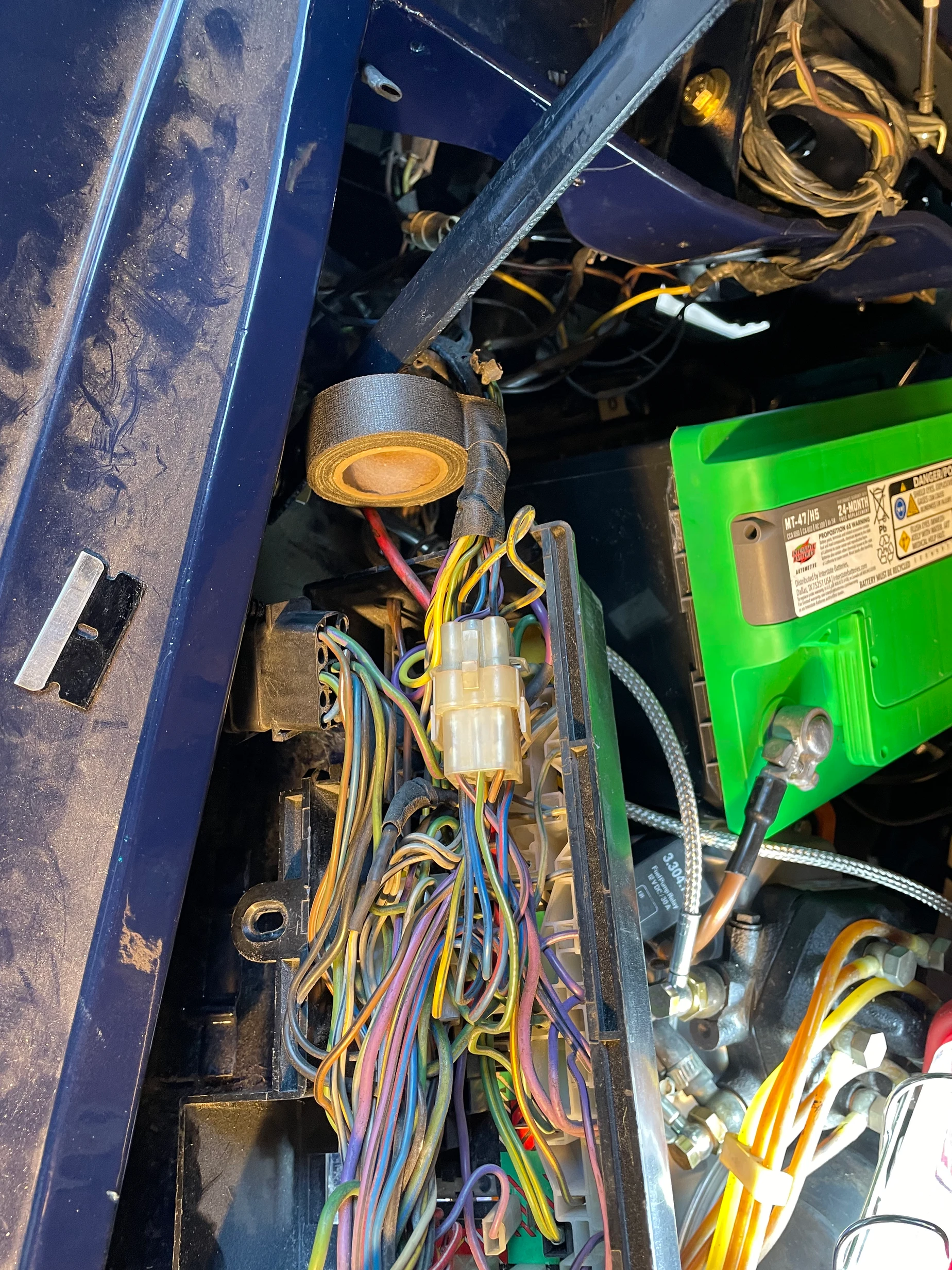

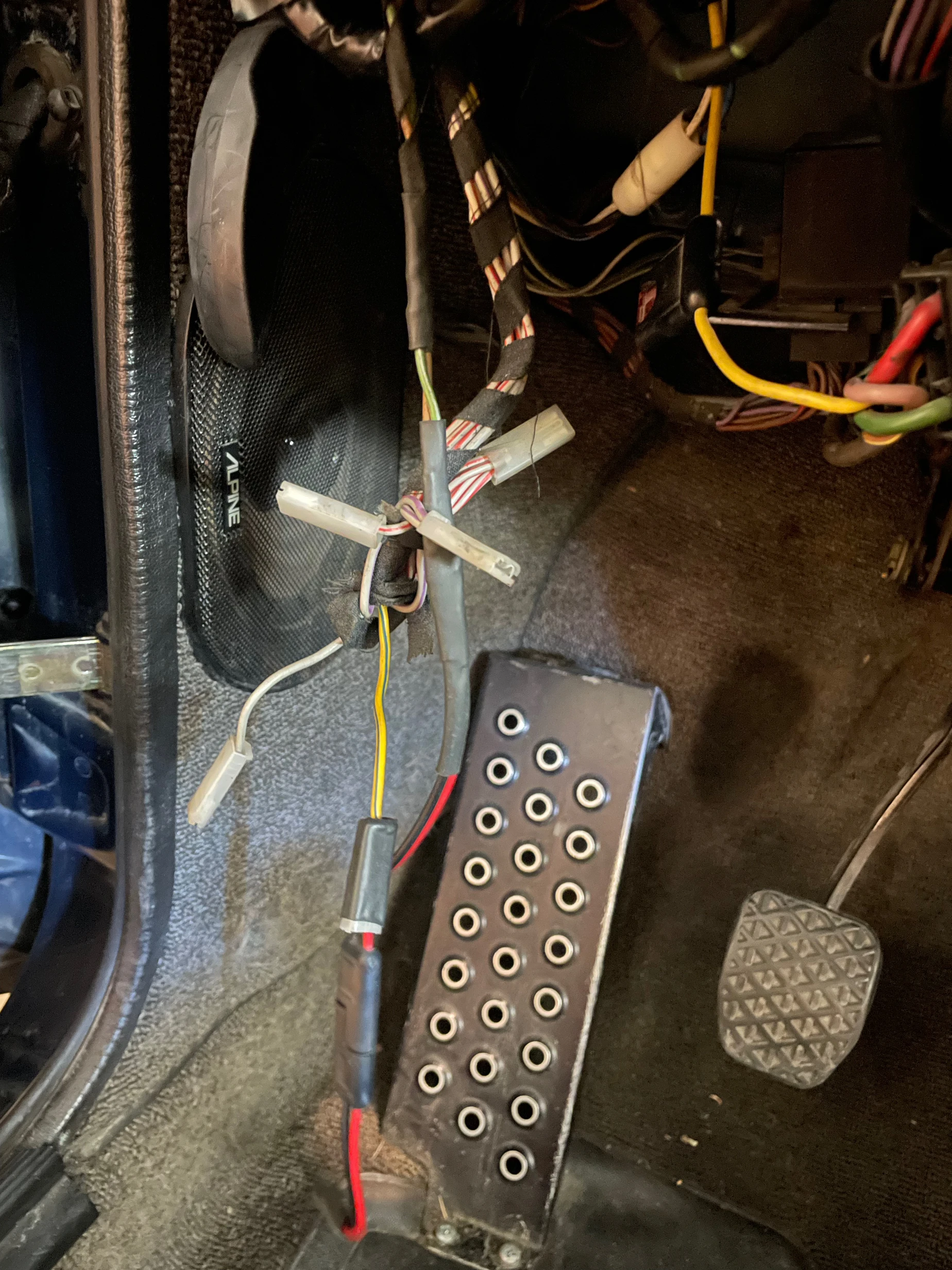

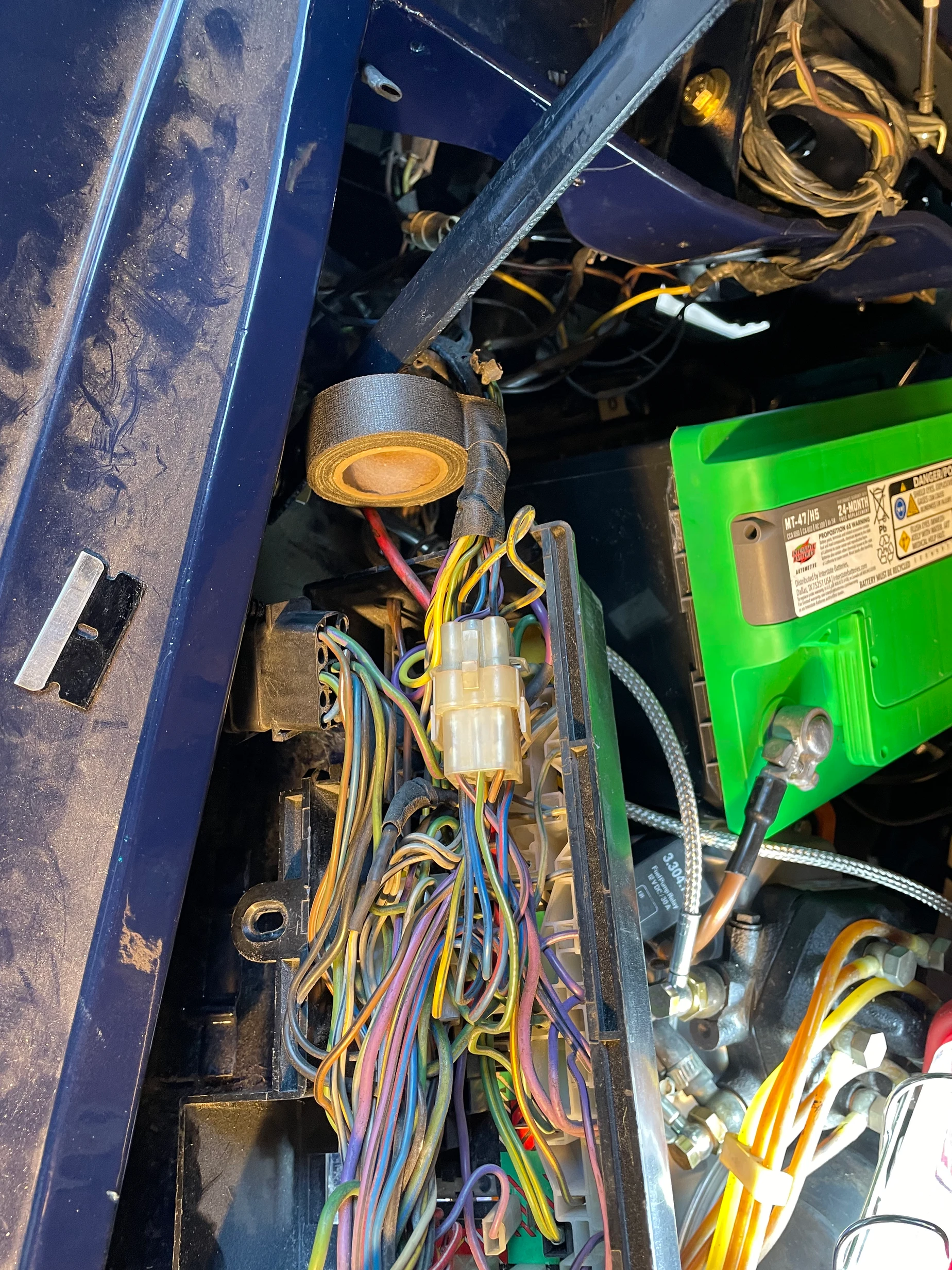

So I tinkered. I took off the electrical tape someone installed in a fit of ugliness and re-wrapped the wiring harness with new cloth tape.

So I tinkered. I took off the electrical tape someone installed in a fit of ugliness and re-wrapped the wiring harness with new cloth tape.

I take out the old, non-functional antenna and put in a new one (forget that there was no center console, let alone stereo in the car).

I take out the old, non-functional antenna and put in a new one (forget that there was no center console, let alone stereo in the car).

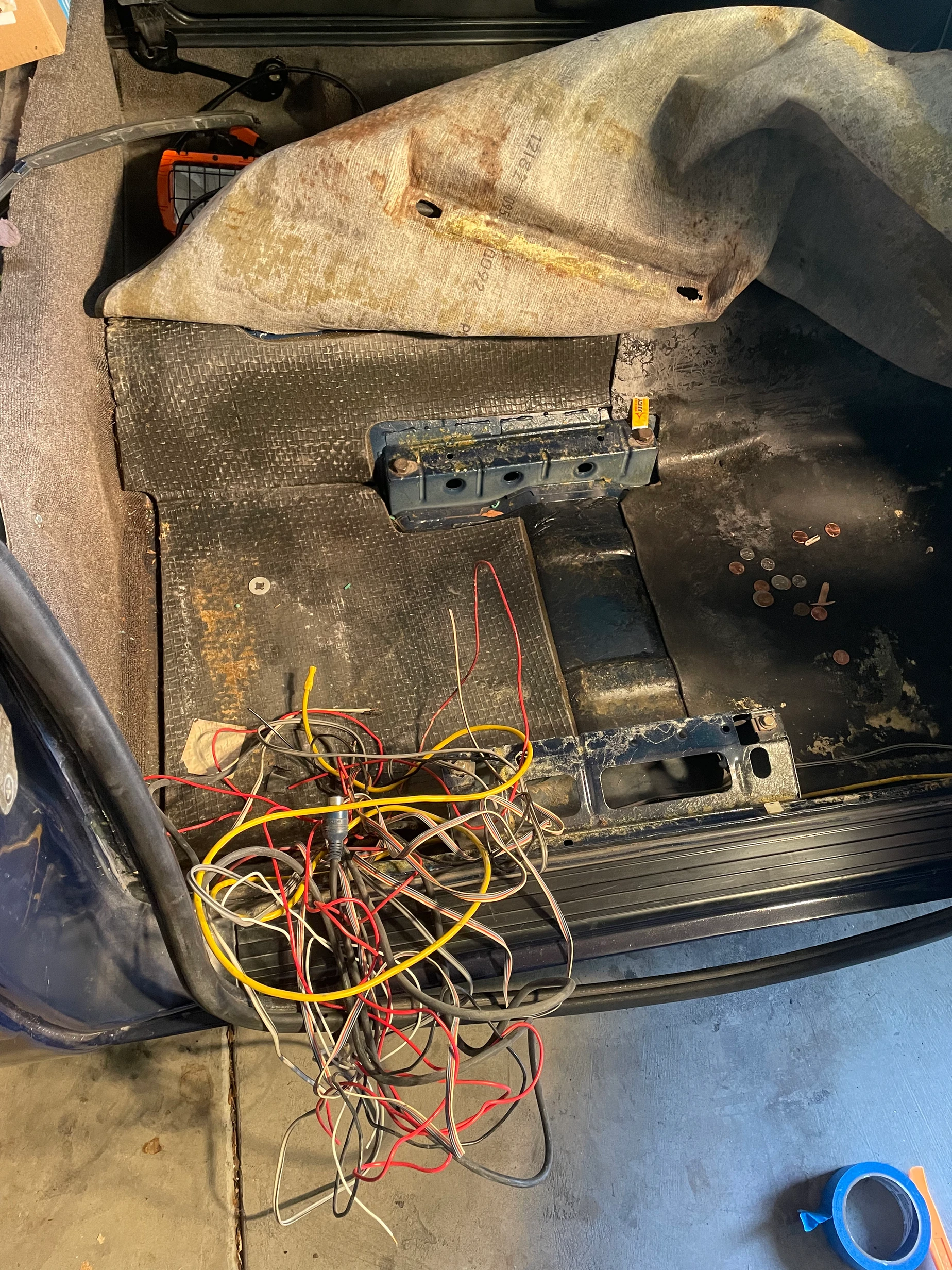

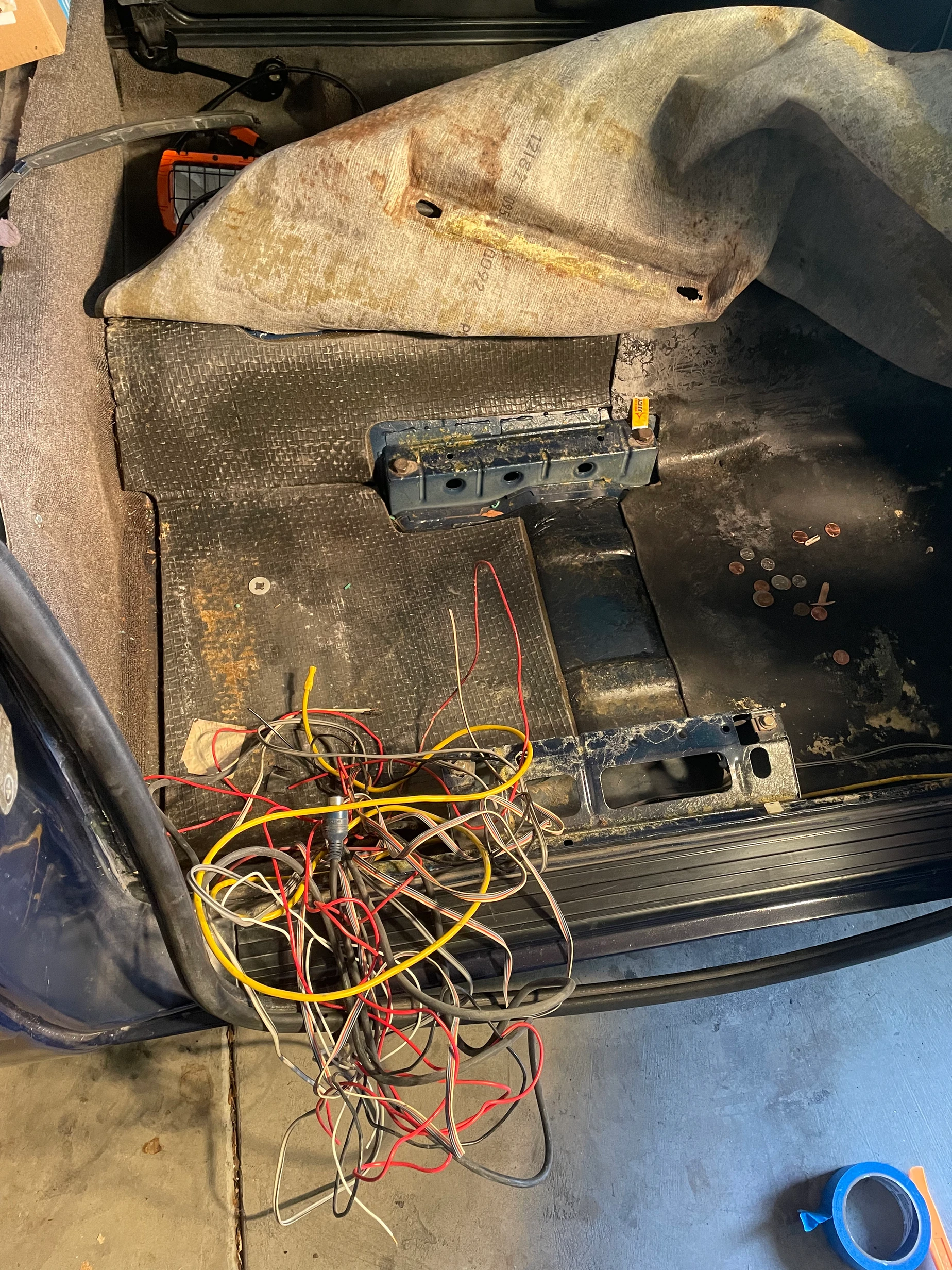

I traced down extra and errant wiring, cleaning messes in the engine compartment and under the dash.

I traced down extra and errant wiring, cleaning messes in the engine compartment and under the dash.

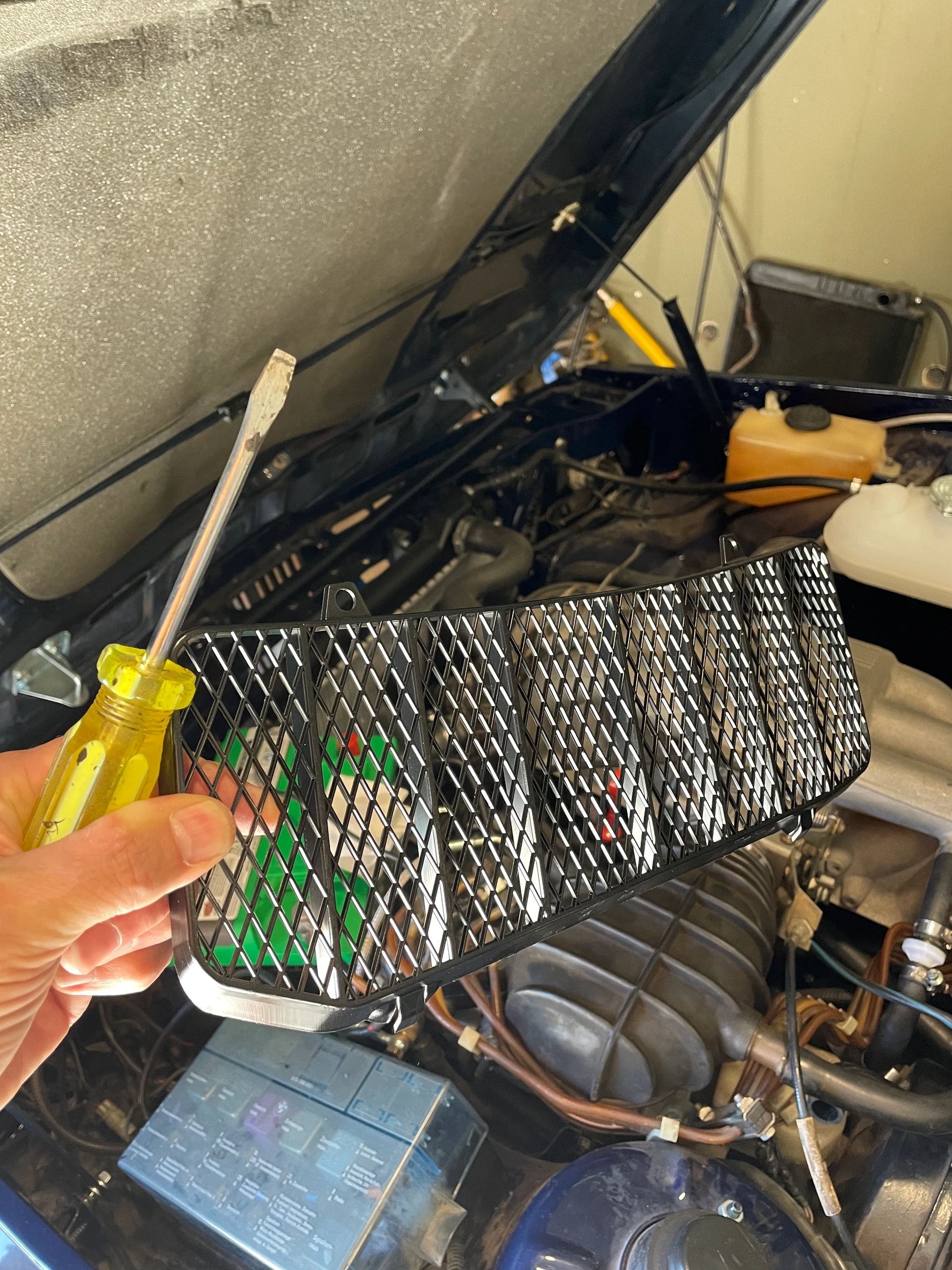

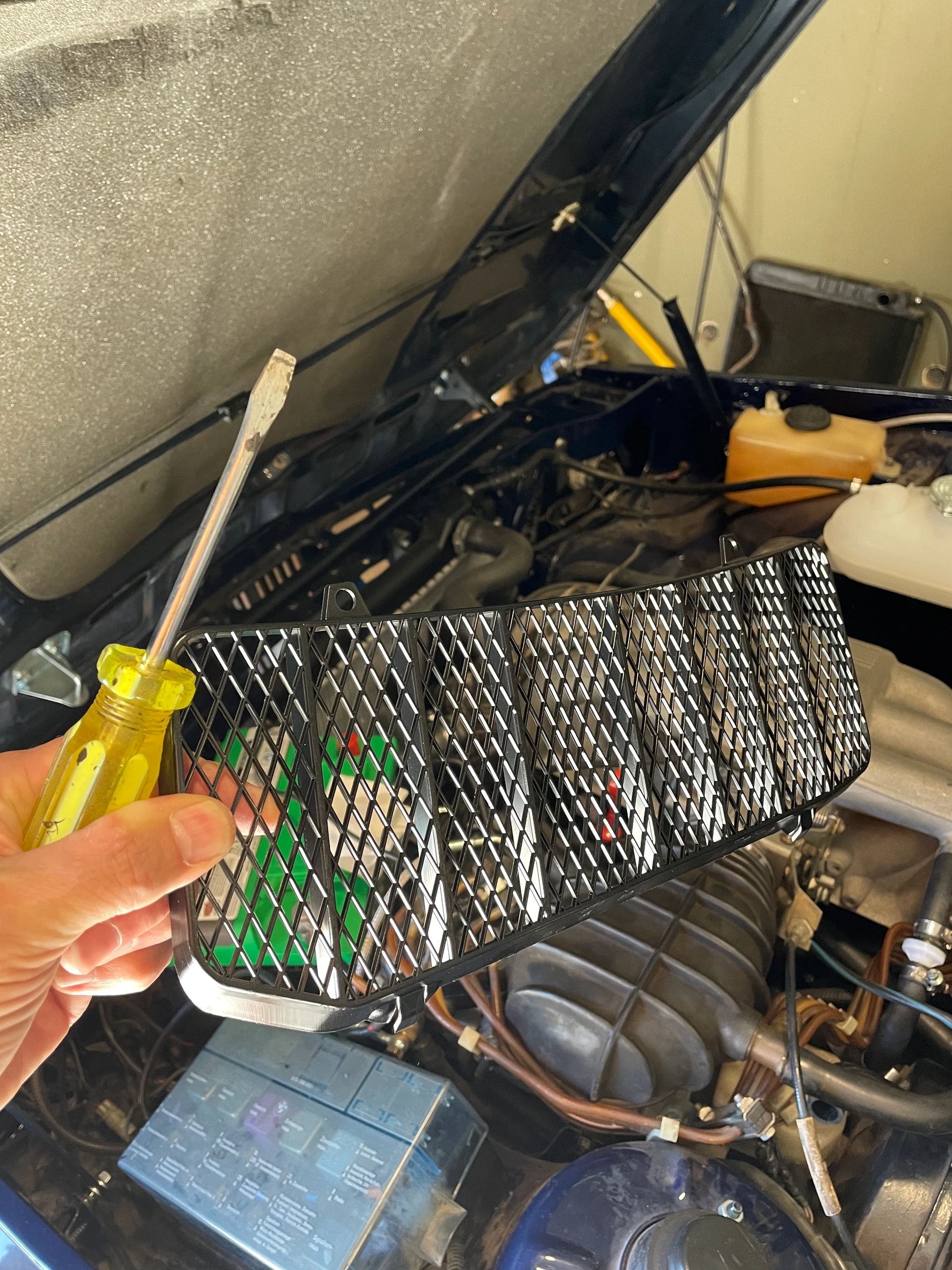

Several little parts were added, like the leaf guards in the hood.

Several little parts were added, like the leaf guards in the hood.

And, I did the one thing that is fairly easy yet yields big results and nice money shots: installed the freshly recovered seats in the blingy Alpina cloth.

And, I did the one thing that is fairly easy yet yields big results and nice money shots: installed the freshly recovered seats in the blingy Alpina cloth.

Other little things like cleaning the carpet, and rewiring the Hella big/little headlights helped move things along.

Other little things like cleaning the carpet, and rewiring the Hella big/little headlights helped move things along.

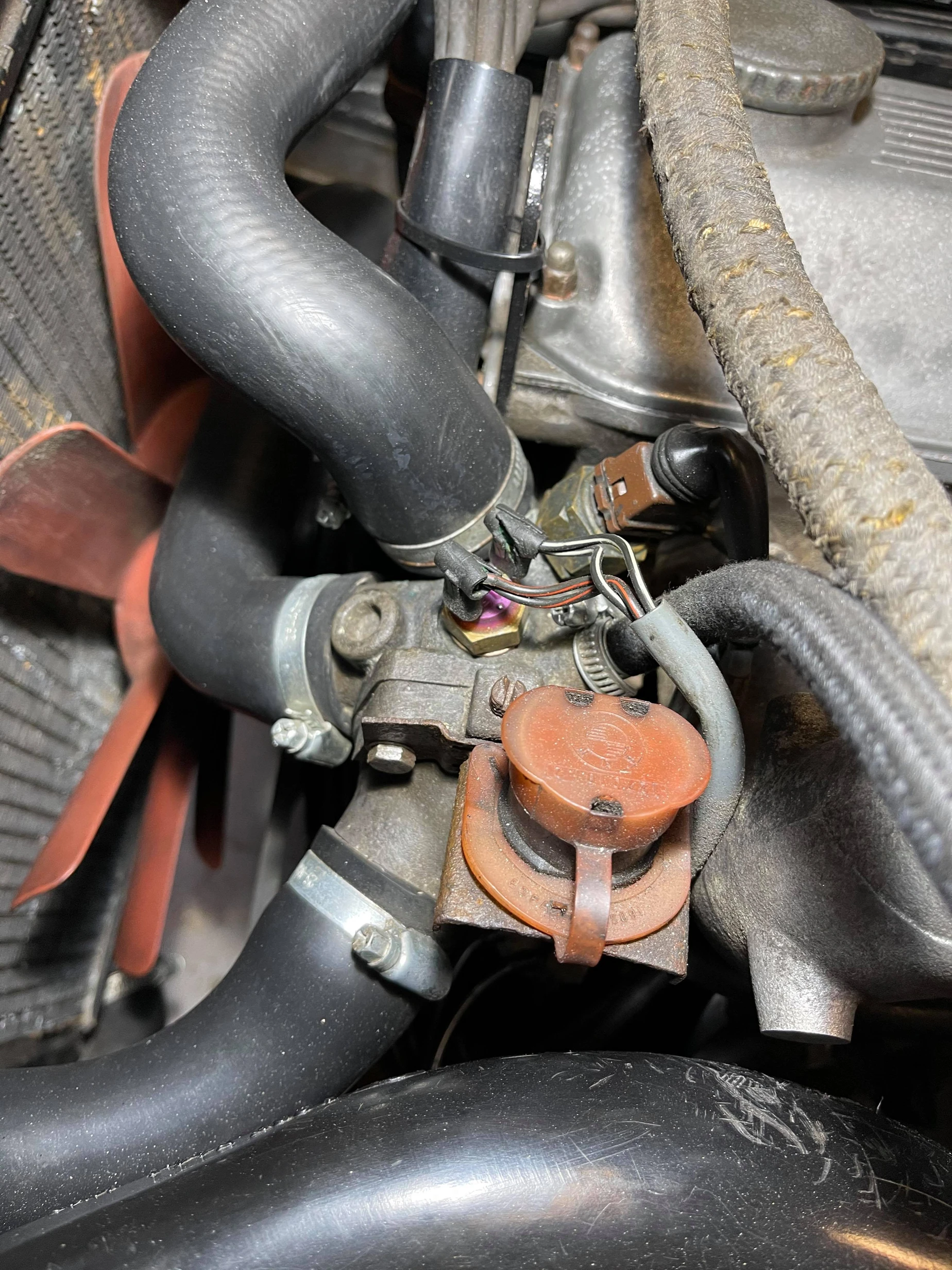

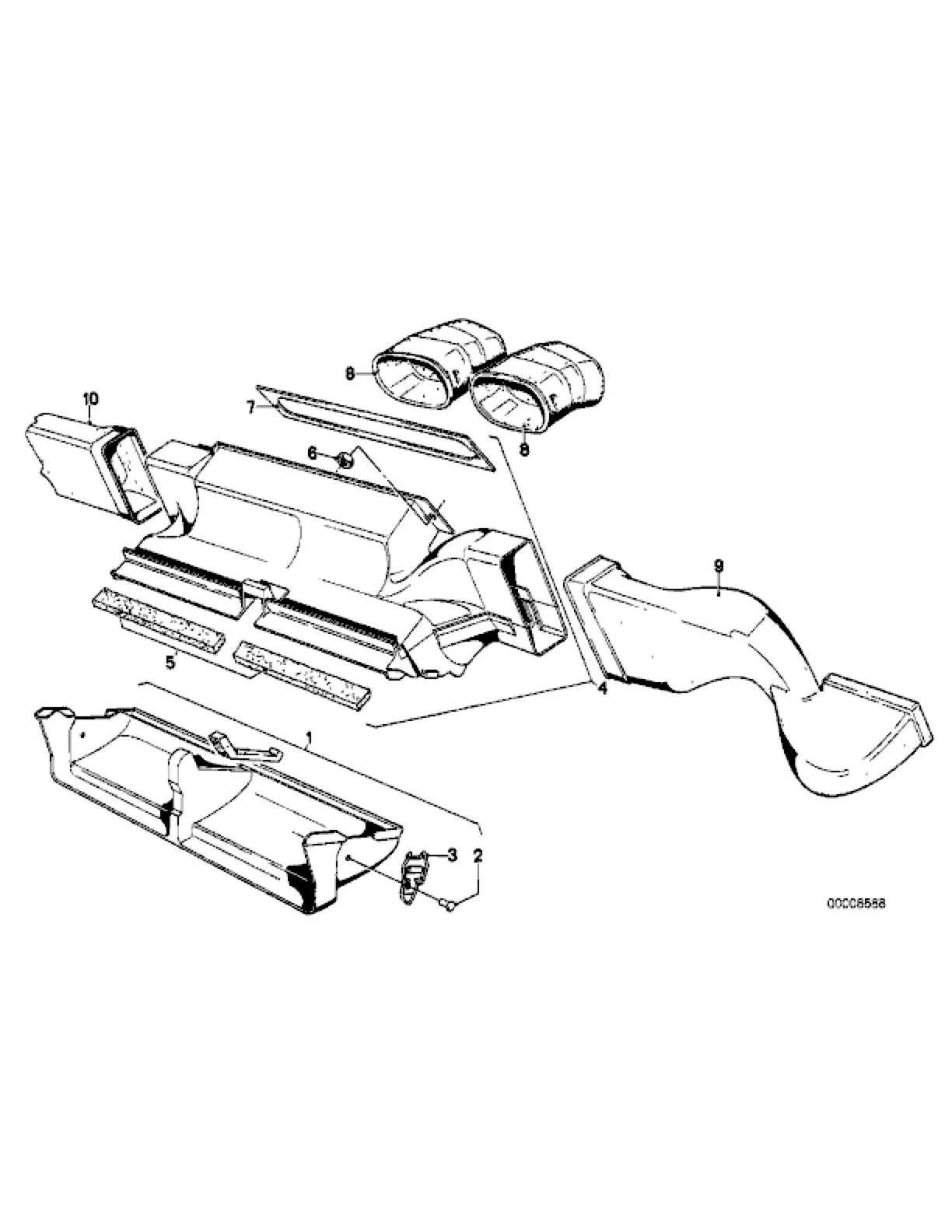

But then Summer became Fall and things stalled to a crawl, mostly due to festering frustration. Why was I frustrated? Heater problems. No, not the garage wasn’t heated. Rather, the problem was the heater in the car; specifically, my tinkering under the dash revealed that the heater ducting was removed along with the dash when it was taken out some 5 years ago (to have the cracks repaired); when the body shop reinstalled the dash they forgot to put the heater ducting back in first.

But then Summer became Fall and things stalled to a crawl, mostly due to festering frustration. Why was I frustrated? Heater problems. No, not the garage wasn’t heated. Rather, the problem was the heater in the car; specifically, my tinkering under the dash revealed that the heater ducting was removed along with the dash when it was taken out some 5 years ago (to have the cracks repaired); when the body shop reinstalled the dash they forgot to put the heater ducting back in first.

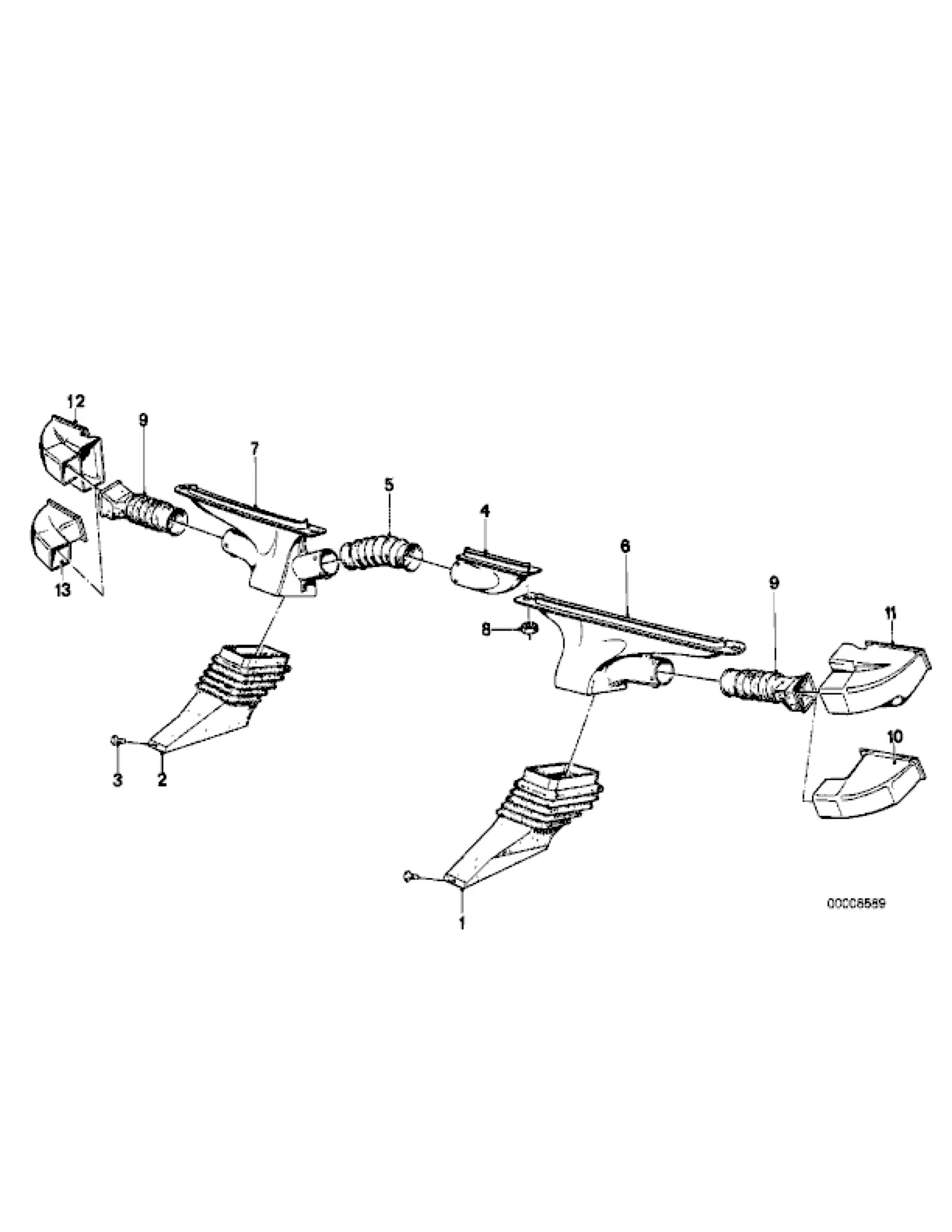

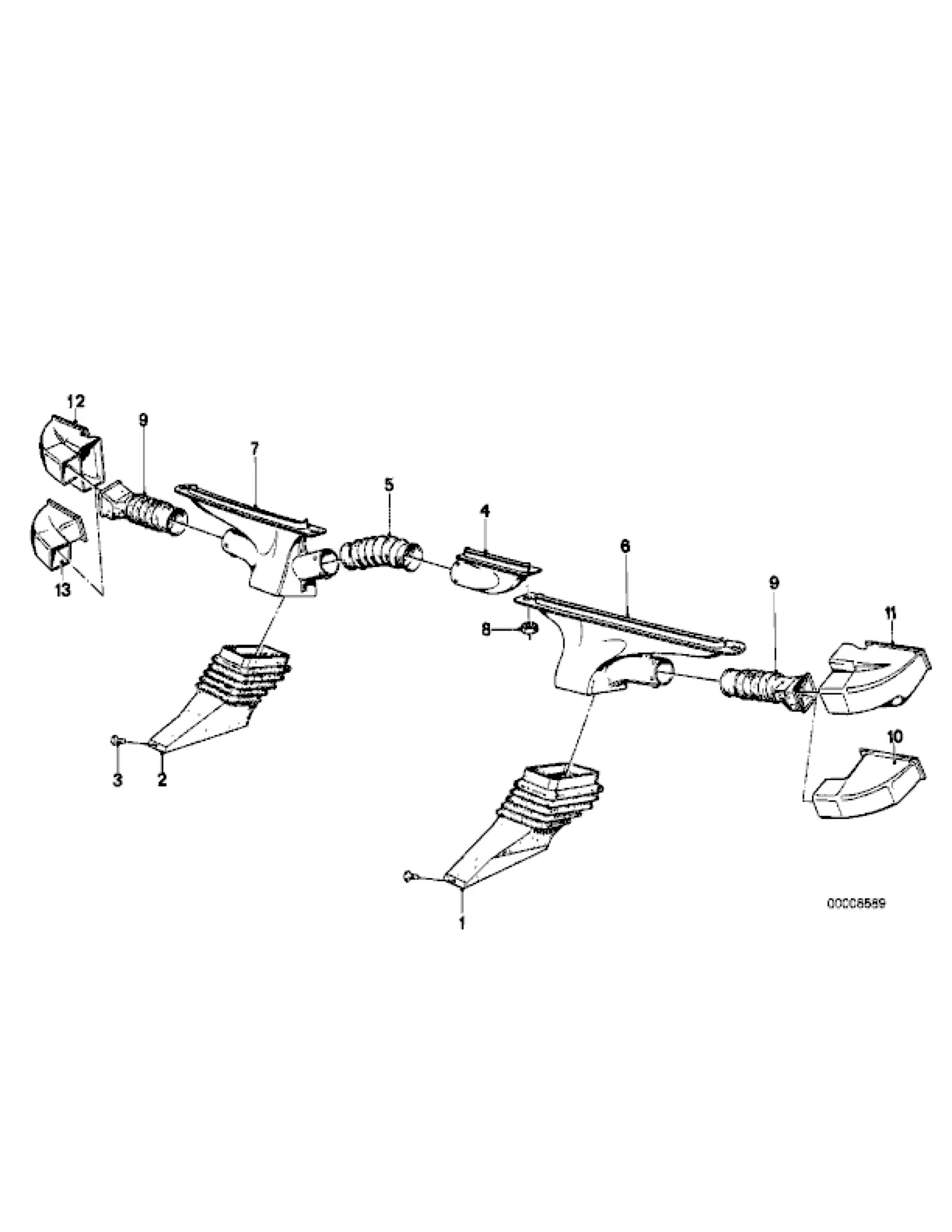

With some ingenuity I was able to squeeze almost all the ducting in place except for one last piece. But, oh that last one. Try as I might, there just wasn’t enough room to maneuver it in there……

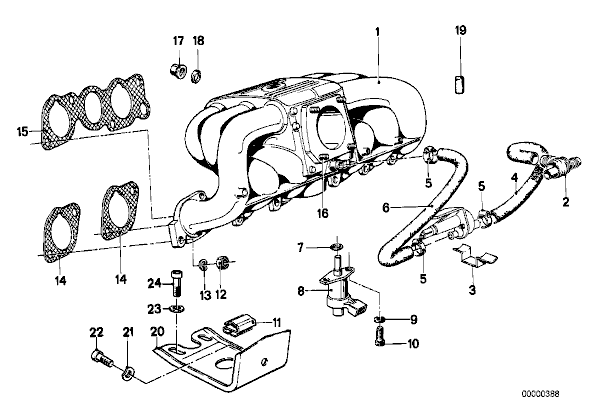

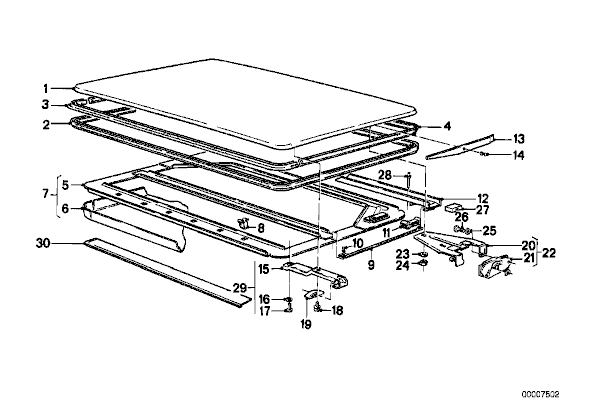

defroster ducting as shown in the parts “book”

defroster ducting as shown in the parts “book”

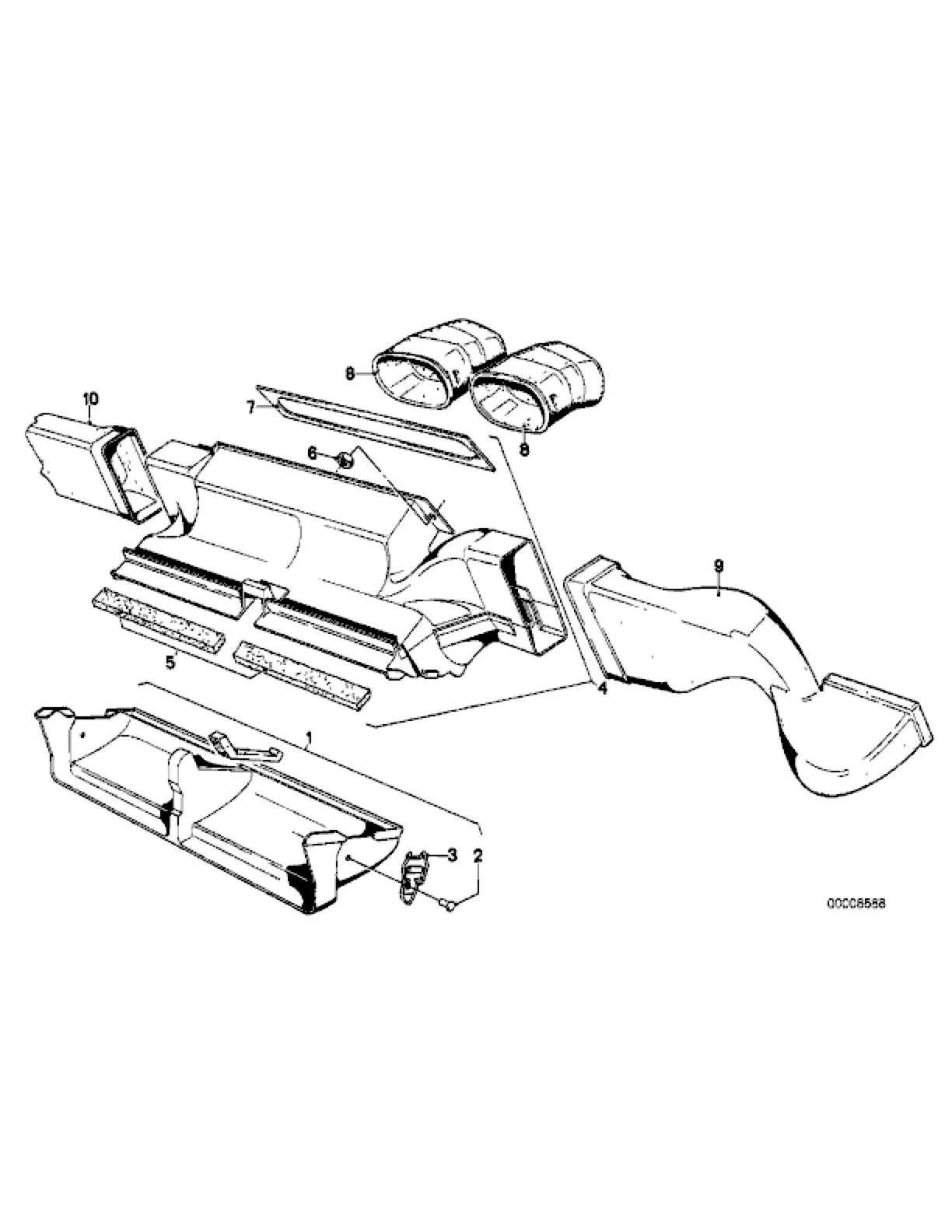

heater ducting as shown in parts “book”

heater ducting as shown in parts “book”

Frustrated, I walked away from the car for a while. After a couple of months without any progress, my long-suffering wife finally prodded me. I realized the enormity of the project was overwhelming me. True, it was great to have the car nearby, instead of two hours away. But I had finished the tinkering and it was time to do the real work. And for that, there was a lot of comfort in having it in a shop, surrounded by many mechanically minded brains happy to help at every turn. Not having a lift at home also made things tough; that was the only way for me to work under a car given my vertigo. All this killed any joy I found working on the car.

I started to wonder if I should bring the car to a shop for completion. It was not a step to be taken lightly. I took pride in re-assembling the car myself. It was truly my creation, my baby. But I knew my limits and learned that there were things, no matter how successful I was, that were above my paygrade: color sanding the paint, fixing the sunroof mechanism, fine tuning the injection, installing that last piece of heater ducting. So, I had already come to the conclusion that someone else was going to bring the car across the finish line. The only question was when.

Eventually, I decided to finish as many of the punch-list items as I could before getting it to the shop that was going to help towards completion. I wanted to try to start the car, so the engine got populated with spark plugs and fluids and other small but necessary items. Once done, a mechanic friend came over for an afternoon and we tried to get it started. We made some progress; it would crank over but not catch. We verified fuel but ran out of time before confirming spark. And that was the last significant attempt. A short while later, I had the car towed away again, this time to a shop that specializes in older BMWs.

They aren’t finished, in fact they pretty much just started. They get to my car in between their regular work; I’m in no rush and they aren’t either, really. But they got it started and are making the progress that I couldn’t. They also found that the brakes are acting up and it may need a new booster or master cylinder. For me, just hearing it run was great. I’m an amateur motor assembler and worry about I did wrong until the thing runs without grenading. We’ve crossed that line, so I guess I didn’t fuck anything up too much.

They aren’t finished, in fact they pretty much just started. They get to my car in between their regular work; I’m in no rush and they aren’t either, really. But they got it started and are making the progress that I couldn’t. They also found that the brakes are acting up and it may need a new booster or master cylinder. For me, just hearing it run was great. I’m an amateur motor assembler and worry about I did wrong until the thing runs without grenading. We’ve crossed that line, so I guess I didn’t fuck anything up too much.

<VIDEO of motor running>

The fact that the car is at a shop and that it’s running has brought back some momentum. And, more importantly, I’ve mapped out the next steps. The body shop I used on some other cars is two blocks away and they’re on-board for color sanding the paint, installing the Alpina stripes and rear spoiler, etc.

The biggest question mark with the car is still the heater; if the shop can get the last of the ducting in without removing the dash, then the control unit can go in and the interior can be buttoned-up. If not, then the dash has to come out again, which has a snowballing effect: the windshield has to come out to remove the dash. If the windshield is out, I should replace the new headliner, due to some issues with the fitment of the current one—and a few mistakes in cutting holes for the sunroof cranks and such. That’s a good amount of work, and costly, but worth it in the end to get everything right.

This is no time for cutting corners and a recent Bring-a-Trailer auction of an e21 B6 2.8 drives that point home: This car sold for $141,000 and it makes me wonder what mine is worth once completed. Sure, it’s not a B6. But Buchloe-built e21 C1s are actually rarer than B6s (In the e21 chassis, Alpina built 462 C1s and 534 B6s according to Paulo Tumminelli in the definitive book on Alpina history, OAL-BB 50: 50 Years of BMW Alpina Automobiles). And with the 2.8 stroker M20 motor, it should have the same or similar performance to the B6. I don’t expect it has B6 value but it should be a pretty nice and rare Buchloe-built C1.

But the value of car right now is solely what it means to me. And as alluded above, it is my baby, my creation because of all my blood, sweat and tears that have gone into it. Of course, all my previous projects were my babies for the same reasons and I ended up selling them after a couple of years and moving on to the next project. From that I realized I liked the process as much—maybe even more—than driving the thing. But times have changed and the projects are much more taxing on my older body and just maybe that has flipped. In the past the projects weren’t fatiguing or frustrating, they were joyous adventures. Maybe in my old age I’ll appreciate journeying in the car more than the journey of building it. Time will tell.

In the meantime, I have this in a conspicuous place, reminding me of what it’ll look like completed and to motivate me.

by alpinac1_pn9him | Apr 12, 2022 | Uncategorized

When I left you, dear reader, on New Years Eve 2021 the sunroof was being put together and I ticked off a list of things that still needed to be done to get the car back on the road. The list was significant – finish the engine electrical, populate the interior, including all the dash components, heater, console, and more – but comparatively short, given how long the list was when the pandemic started.

Since then the sunroof and hood have been installed and the car is ready to be trucked down from Sacramento to my garage in the San Francisco Bay Area, some 100 or so miles. Just for a little perspective, the picture below is from October 2017 when Stu came down with his truck and trailer to take the motorless shell up to Sacramento for the paint job.

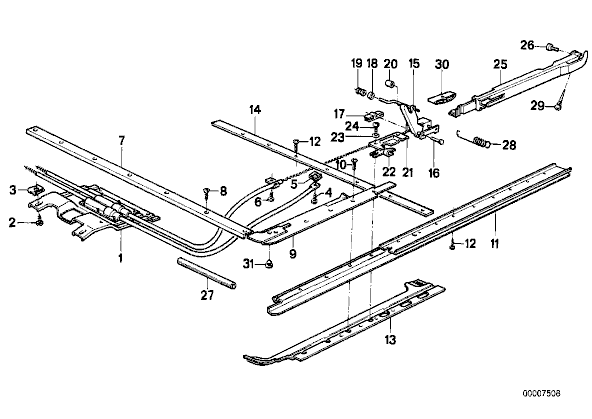

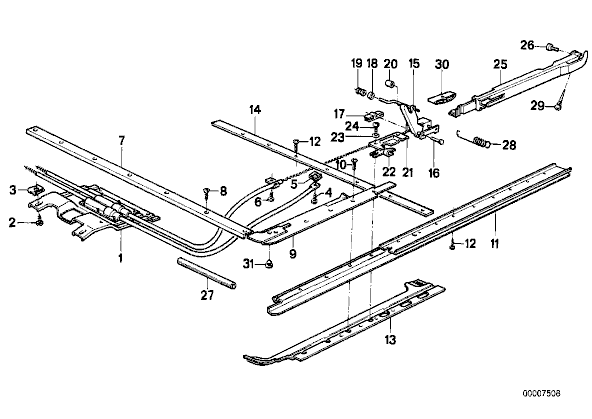

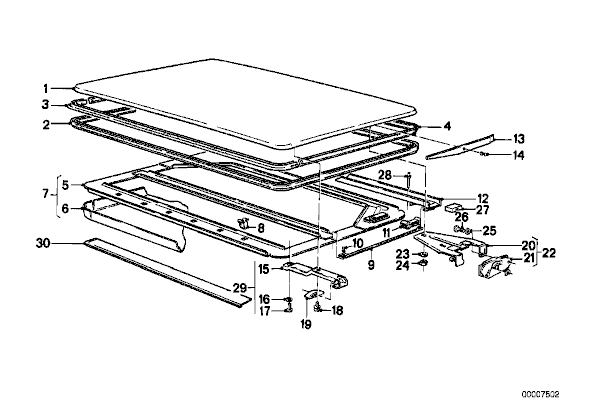

Getting the sunroof back in was not easy. The entire mechanics were disassembled and most of the little parts did not stay with the shell when the body shop closed. Sourcing those small but necessary parts takes time and ingenuity. Some parts were available from BMW, some were on eBay new or used, some we got from a junk yard with an old 6-series (thankfully BMW used the same parts in several different platforms). That took many trips up to Sacramento to install the parts I got and figure out the ones I needed to get. Slow and frustrating progress.

Getting the sunroof back in was not easy. The entire mechanics were disassembled and most of the little parts did not stay with the shell when the body shop closed. Sourcing those small but necessary parts takes time and ingenuity. Some parts were available from BMW, some were on eBay new or used, some we got from a junk yard with an old 6-series (thankfully BMW used the same parts in several different platforms). That took many trips up to Sacramento to install the parts I got and figure out the ones I needed to get. Slow and frustrating progress.

Above I told you the sunroof was in. And that is true. But it was a misleading but factual statement (my lawyer training coming through!). We finally got all the parts and were able to put the sunroof in the car. But we couldn’t get it operating. Or at least fully operating. The tilt works but not the back and forth. I’m sure with time and energy it will work but I was up for two days and had other things to accomplish before leaving. Plus, I really don’t like sunroofs anyway, so having it in but not working is not anything even near a hardship for me. Finally, the sunroof and the hood were the two final steps in getting the car water tight so it could be trucked back home.

Above I told you the sunroof was in. And that is true. But it was a misleading but factual statement (my lawyer training coming through!). We finally got all the parts and were able to put the sunroof in the car. But we couldn’t get it operating. Or at least fully operating. The tilt works but not the back and forth. I’m sure with time and energy it will work but I was up for two days and had other things to accomplish before leaving. Plus, I really don’t like sunroofs anyway, so having it in but not working is not anything even near a hardship for me. Finally, the sunroof and the hood were the two final steps in getting the car water tight so it could be trucked back home.

I was working on the hood also the day we got the sunroof in. As with the sunroof, the hood was disassembled for paint and many of the little parts were missing. I was able to find most new or on eBay but they were primered, not painted. So I got some rattle cans from paintscratch.com and painted them in between the sunroof installation. By the next morning all the parts were ready to be put in the hood. By happenstance an e21 was in the shop for me to use as a template; I’d look at the white car there and go back to my hood and install parts over and over. Soon three of us carried the hood over to the shell to reunite them. Bolting it on was straight-forward but took some time. The tensioners are not on right I suspect, as the hood won’t stay up on it’s own. But the car is water tight and ready to come home.

Now we just need to find a time when I’m in town and Stu can truck it down. Once it is back in my garage I’ll populate the interior and wire up the few remaining electrical items and figure out what else is left unfinished. Oh, and see about getting the sunroof operational and the hood staying in open position.

by alpinac1_pn9him | Dec 31, 2021 | Uncategorized

The title for this post was going to be A New Year, given that I sat down to write this on the morning of New Years Eve, 2021. But that title was taken by a 4-year-old post discussing the paint—an event so long ago I forgot the title had been used already. Yes, a lot of time has gone by but, besides retiring from my day job, my daughter graduating college, a global pandemic, and my son going off to college, it feels like not much has happened. Ok, I guess a lot has happened. Just not to the car, that is.

That theme—that life continues to move forward but the car doesn’t really—is both true and false. It’s been a good six months since my last post, enough time to complete the car. Of course that hasn’t happened and the progress that has been made doesn’t feel like half a year’s worth.

In that six months I’ve driven across the country twice, once by myself in a 1992 BMW M5 wagon I bought to replace my daily driver and then a second time with my daughter and her dog, bringing them home for the holidays. Both trips were fun but I would have preferred not have hit the deer and totaled the X3 that my daughter and I were taking across the country.

The M5 wagon in Utah

The totaled X3

Once back from my travels, I made my way up to Sacramento to work on the car. The motor is almost done. Fuel injection was populated. Headers bolted up. Cooling system—radiator and hoses—installed.

Rear windows put in and parts for door trim being sourced from around the world.

Rear windows put in and parts for door trim being sourced from around the world.

And, most recently, the sunroof is finally being addressed. First was cleaning up the sunroof frame and installing the headliner on it. Next up will be reinstalling the sunroof mechanics, the headliner frame and then the roof itself. That may happened next week.

And, most recently, the sunroof is finally being addressed. First was cleaning up the sunroof frame and installing the headliner on it. Next up will be reinstalling the sunroof mechanics, the headliner frame and then the roof itself. That may happened next week.

by alpinac1_pn9him | May 4, 2021 | Uncategorized

A lot has happened since the last post in early December. At the same time, it feels like the project bounced around with little coming to completion. During the hour and a half drive up to Sacramento I’d often review the progress in my mind and wonder if it was time for a new post. But there was no arc to a story; plenty was being done, progress was (slowly) being made. But none of the things I’d been working on were completed—the stories had beginnings, some had middles, but no end. And that, I realized, is the story.

Ok, that’s not completely true. There have been a few things that have been completed. The transmission is in and the rest of the drivetrain buttoned up. Some pesky rust was found on the frame rail, ground out and plates welded in to cover the holes and ensure structural integrity. Yet much of the car—the fuel injection, the cooling system, the interior—is still a work in progress, and progress has been slow. And, little by little, it keeps moving forward.

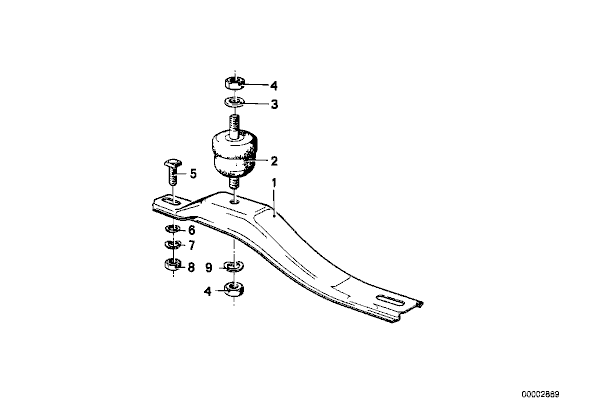

The reoccurring theme with the car, at least in this drive-up-to-Sacramento phase, has been the trying to put together a car that someone else took apart years ago. The transmission exemplifies it: After the motor was dropped in, the transmission was put in—we put the car up high on the lift and lifted in the transmission by hand and stabbed it in the clutch. Once bolted in we realized that we had the wrong rear support bracket (it was from a 5-series) but the transmission was hanging there unsupported; we needed something to hold it up while sourcing the right part. I flipped over the 5-series bracket, which caught a corner of the transmission, barely holding it in place until we got the right part. That took a few weeks: the bracket was NLA and when I found a used one it took awhile to get shipped to my home; it was in the car on my next trip up to the shop.

But eventually, the right support bracket was sourced and in the car, followed by a guibo and the shift linkage, clutch slave and a whole bunch of little things, resulting in a completed drivetrain. That was the good news from under the car.

The bad news was I noticed bubbling on driver’s side frame rail. I poked it and it was crumbly, a sure sign it was rust. A couple of hours with the Dremel tool and I had 3 holes in the frame rail ranging in size from a dime to a quarter or maybe even a half-dollar. After grinding out all the rust, the metal was treated. We cut some plates from steel sheet metal and Stu welded them in over the holes. I ground down the welds and primed it.

The plates being held in by tape, ready to weld

The welds ground down and the plates primed

Meanwhile, with the engine in, I started to populate it. First was the wiring, then the fuel injection. For the wiring, I asked a few folks on the FaceBook e21 page for pictures of the routing of the wiring; using those as guides, I laid out the wiring harness and connected the electrical components. That was relatively easy.

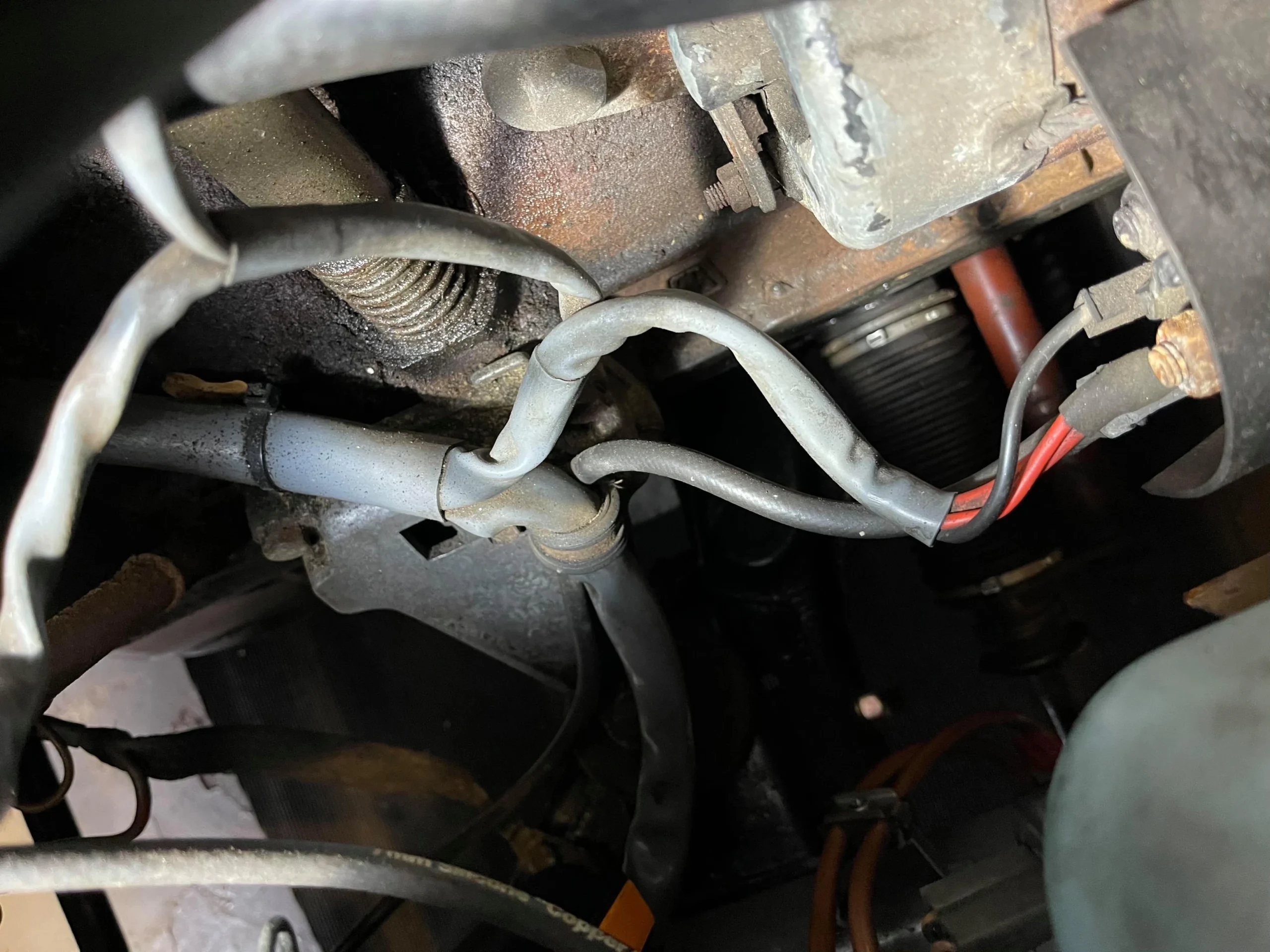

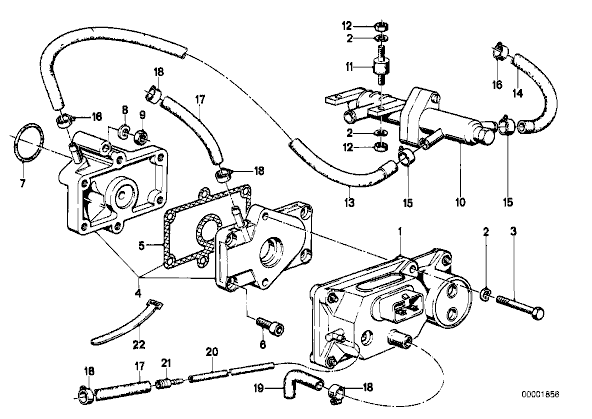

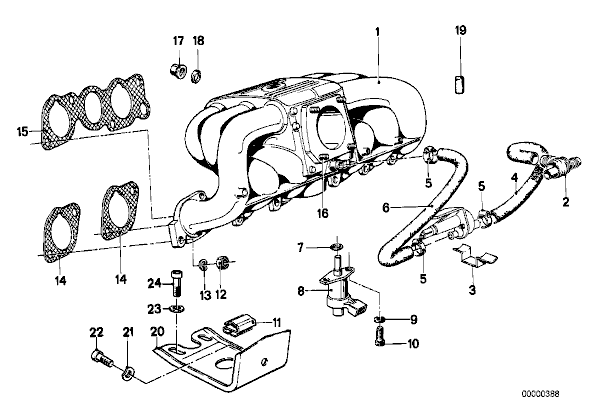

The fuel injection was more challenging. The basics of the Bosch K were easy enough but it wasn’t time for that yet. Figuring out the auxiliary air system was not so simple. I had too many parts and not enough space to fit it all. I consulted the parts pictures on Mobile Tradition website, which showed two different auxiliary air systems, one using electricity to heat it and another heated by the coolant. And I had parts for both. The parts catalog did not present it as an either-or situation and I spent a fair amount of time trying to figure out how the two systems worked together. I also wondered why would BMW have both systems in one car?

After consulting with other e21 323i owners, it became clear I was right to question both systems working in tandem; it was either-or and that my car used the coolant-based system when I tore it apart years ago. Later, I figured out that the second system was from the spare intake manifold I had. I could have used either but decided to stick with what the car came with, even though it was more complicated. (An interesting side-note: both systems used coolant as a warming agent on the intake system. The system I call coolant based system has coolant run under the fuel pressure regulator (in pic below) and then to the auxiliary air valve. The so-called electrical system uses an electronically warmed auxiliary air valve but runs coolant through the throttle body, I guess to warm the air as it goes into the intake manifold. Why they wanted to do that, I don’t know!)

The electrical system

The extra intake manifold with the electric auxiliary air valve

Once I knew which system I wanted to use, I needed to figure out the routing of the hoses. With that done, it was simply a matter of attaching the hoses and bolting the actual valve to the underside of the manifold. Of course, I wanted to replace worn hoses—and was both easy and difficult. It’s easy to attach new hoses and to source standard sized ones that don’t have weird twist and turns in them. But some were special order parts, further delaying progress because the only way to get them was from Walloth and Nesch in Germany. For some inexplicable “reason” BMW has a schizophrenic policy on US vendors selling euro-only parts. Some euro-only parts can be sourced by US vendors without any drama, but for others you have to show a registration proving you own such a car—and sometimes after doing that BMW still won’t allow them to be sold here. When that happens, the parts have to be ordered from German suppliers or foreign eBay vendors. If I can’t find the parts on eBay, Walloth and Nesch is often the solution, but given their 49 euro shipping charge, I try to bundle parts into a single order, causing even more delays.

The auxiliary air system installed

Planning ahead—and bundling parts orders—has been a challenge for me, given my myopic approach of simply attacking what is in front of me. I’ve been trying to teach myself to think ahead and, in that vein, I realized I’d need to put in the headers soon. The car had came with SuperSprint headers but they were old and rusty.

So, I took them to a header shop and had them welded up and ceramic coated. They look great now. It was nice, too, to do this in advance of actually needing them and not delaying the project while they were getting restored. Score one for the home team!

A bunch of little tasks have been completed, too. For example, the door panels are back on, with the handles, cranks, and arm rests (which were found in the strangest places in the shop). A new radiator and coolant overflow were ordered from Walloth and Nesch; including the 49 euro shipping, they were over $100 cheaper than a US vendor, believe it or not!

The exhaust was just hanging there, without the “doughnut” supports.

Five minutes later (after a week of waiting for the part), it was done. Were it was all that easy!

We all knew that eventually the fuel injection would be installed on the engine and that day finally came. Because of the modifications to the motor, the stock fuel injection wasn’t going to keep up with the fuel demands of the mild cam increase and significant extra displacement. So I Frankensteined together a bunch of Bosch K parts that Porsche used on the 2.7 liter euro 911S; that motor put out about 210 horsepower, so it flowed enough fuel for my motor. I also arrived at these parts in consultation with another C1 2.3 owner who built a similar motor.

Because the parts were Frankensteined together, I did a test fit (which I didn’t quiet finish yet). But first I had to clean up the remaining parts that I was using. The air box got cleaned and painted. The support base that connects the air flow sensor to the air box went into the media blaster to get cleaned up too.

The support bracket before getting blasted.

The support bracket cleaned and on half of the air box

Bolting the air flow sensor on was straight-forward

Before going further, those components needed to be test-fitted. I also needed to figure out what other parts were necessary to install the fuel injection. A couple more things were ordered and the car put away until they arrive.

After every session, the car has to be raised up and a very, very dusty e30 M3 is tucked in underneath. Good company!

Alas, the list of things to be done is still long: finish the fuel injection, figure out how to wire in the coil, install the headers, finish the headliner, install the sunroof, populate the dash (gauges, heater controls, etc.) that was disassembled when it was sent to Just Dashes to repair the cracks. Once that is done, it can be fired up and see if the damn thing even runs. Feels like that is months away. My goal was to drive the car to Monterey this August for car week. It feels like that is slipping further and further into the unlikely category….

Once at home, I put in the heater control panel (not hooked up, but at least there’s not a big hole in the middle of the dash!), tried to run down the short grounding out the gas gauge (no success), swapped in my extra speedo to see if that cured the problem (it didn’t; likely the speedo cable or the fitting at the transmission), cleaned up wiring issues under the dash, attended to many, many little details, and tried to straighten the off kilter steering wheel.

Once at home, I put in the heater control panel (not hooked up, but at least there’s not a big hole in the middle of the dash!), tried to run down the short grounding out the gas gauge (no success), swapped in my extra speedo to see if that cured the problem (it didn’t; likely the speedo cable or the fitting at the transmission), cleaned up wiring issues under the dash, attended to many, many little details, and tried to straighten the off kilter steering wheel.

So I tinkered. I took off the electrical tape someone installed in a fit of ugliness and re-wrapped the wiring harness with new cloth tape.

So I tinkered. I took off the electrical tape someone installed in a fit of ugliness and re-wrapped the wiring harness with new cloth tape. I take out the old, non-functional antenna and put in a new one (forget that there was no center console, let alone stereo in the car).

I take out the old, non-functional antenna and put in a new one (forget that there was no center console, let alone stereo in the car). I traced down extra and errant wiring, cleaning messes in the engine compartment and under the dash.

I traced down extra and errant wiring, cleaning messes in the engine compartment and under the dash.

Several little parts were added, like the leaf guards in the hood.

Several little parts were added, like the leaf guards in the hood.

And, I did the one thing that is fairly easy yet yields big results and nice money shots: installed the freshly recovered seats in the blingy Alpina cloth.

And, I did the one thing that is fairly easy yet yields big results and nice money shots: installed the freshly recovered seats in the blingy Alpina cloth.

Other little things like cleaning the carpet, and rewiring the Hella big/little headlights helped move things along.

Other little things like cleaning the carpet, and rewiring the Hella big/little headlights helped move things along.

But then Summer became Fall and things stalled to a crawl, mostly due to festering frustration. Why was I frustrated? Heater problems. No, not the garage wasn’t heated. Rather, the problem was the heater in the car; specifically, my tinkering under the dash revealed that the heater ducting was removed along with the dash when it was taken out some 5 years ago (to have the cracks repaired); when the body shop reinstalled the dash they forgot to put the heater ducting back in first.

But then Summer became Fall and things stalled to a crawl, mostly due to festering frustration. Why was I frustrated? Heater problems. No, not the garage wasn’t heated. Rather, the problem was the heater in the car; specifically, my tinkering under the dash revealed that the heater ducting was removed along with the dash when it was taken out some 5 years ago (to have the cracks repaired); when the body shop reinstalled the dash they forgot to put the heater ducting back in first. defroster ducting as shown in the parts “book”

defroster ducting as shown in the parts “book” heater ducting as shown in parts “book”

heater ducting as shown in parts “book” They aren’t finished, in fact they pretty much just started. They get to my car in between their regular work; I’m in no rush and they aren’t either, really. But they got it started and are making the progress that I couldn’t. They also found that the brakes are acting up and it may need a new booster or master cylinder. For me, just hearing it run was great. I’m an amateur motor assembler and worry about I did wrong until the thing runs without grenading. We’ve crossed that line, so I guess I didn’t fuck anything up too much.

They aren’t finished, in fact they pretty much just started. They get to my car in between their regular work; I’m in no rush and they aren’t either, really. But they got it started and are making the progress that I couldn’t. They also found that the brakes are acting up and it may need a new booster or master cylinder. For me, just hearing it run was great. I’m an amateur motor assembler and worry about I did wrong until the thing runs without grenading. We’ve crossed that line, so I guess I didn’t fuck anything up too much.

Getting the sunroof back in was not easy. The entire mechanics were disassembled and most of the little parts did not stay with the shell when the body shop closed. Sourcing those small but necessary parts takes time and ingenuity. Some parts were available from BMW, some were on eBay new or used, some we got from a junk yard with an old 6-series (thankfully BMW used the same parts in several different platforms). That took many trips up to Sacramento to install the parts I got and figure out the ones I needed to get. Slow and frustrating progress.

Getting the sunroof back in was not easy. The entire mechanics were disassembled and most of the little parts did not stay with the shell when the body shop closed. Sourcing those small but necessary parts takes time and ingenuity. Some parts were available from BMW, some were on eBay new or used, some we got from a junk yard with an old 6-series (thankfully BMW used the same parts in several different platforms). That took many trips up to Sacramento to install the parts I got and figure out the ones I needed to get. Slow and frustrating progress.

Above I told you the sunroof was in. And that is true. But it was a misleading but factual statement (my lawyer training coming through!). We finally got all the parts and were able to put the sunroof in the car. But we couldn’t get it operating. Or at least fully operating. The tilt works but not the back and forth. I’m sure with time and energy it will work but I was up for two days and had other things to accomplish before leaving. Plus, I really don’t like sunroofs anyway, so having it in but not working is not anything even near a hardship for me. Finally, the sunroof and the hood were the two final steps in getting the car water tight so it could be trucked back home.

Above I told you the sunroof was in. And that is true. But it was a misleading but factual statement (my lawyer training coming through!). We finally got all the parts and were able to put the sunroof in the car. But we couldn’t get it operating. Or at least fully operating. The tilt works but not the back and forth. I’m sure with time and energy it will work but I was up for two days and had other things to accomplish before leaving. Plus, I really don’t like sunroofs anyway, so having it in but not working is not anything even near a hardship for me. Finally, the sunroof and the hood were the two final steps in getting the car water tight so it could be trucked back home.

Rear windows put in and parts for door trim being sourced from around the world.

Rear windows put in and parts for door trim being sourced from around the world.

And, most recently, the sunroof is finally being addressed. First was cleaning up the sunroof frame and installing the headliner on it. Next up will be reinstalling the sunroof mechanics, the headliner frame and then the roof itself. That may happened next week.

And, most recently, the sunroof is finally being addressed. First was cleaning up the sunroof frame and installing the headliner on it. Next up will be reinstalling the sunroof mechanics, the headliner frame and then the roof itself. That may happened next week.

But there’s plenty to still be done. The interior still needs work: There are no seats, the dash has not been populated and lots of little parts are surely missing or broken, including the heater control unit. But that can wait until after we confirm that the car will actually run. To get there, I have a ton of details that need attention: wire in the coil (replaced by an MSD by a previous owner); finish other electric details, like sourcing and attaching battery leads; and plumb in the rest of the fuel delivery system.

But there’s plenty to still be done. The interior still needs work: There are no seats, the dash has not been populated and lots of little parts are surely missing or broken, including the heater control unit. But that can wait until after we confirm that the car will actually run. To get there, I have a ton of details that need attention: wire in the coil (replaced by an MSD by a previous owner); finish other electric details, like sourcing and attaching battery leads; and plumb in the rest of the fuel delivery system.