Slowly, the bottom end progresses

With the crank in the block and the pistons and rods assembled, next was putting them into the cylinders.

First, rods needed to be separated. The bolts were torqued down pretty good and I needed a little help loosening them. An impact wrench does the trick.

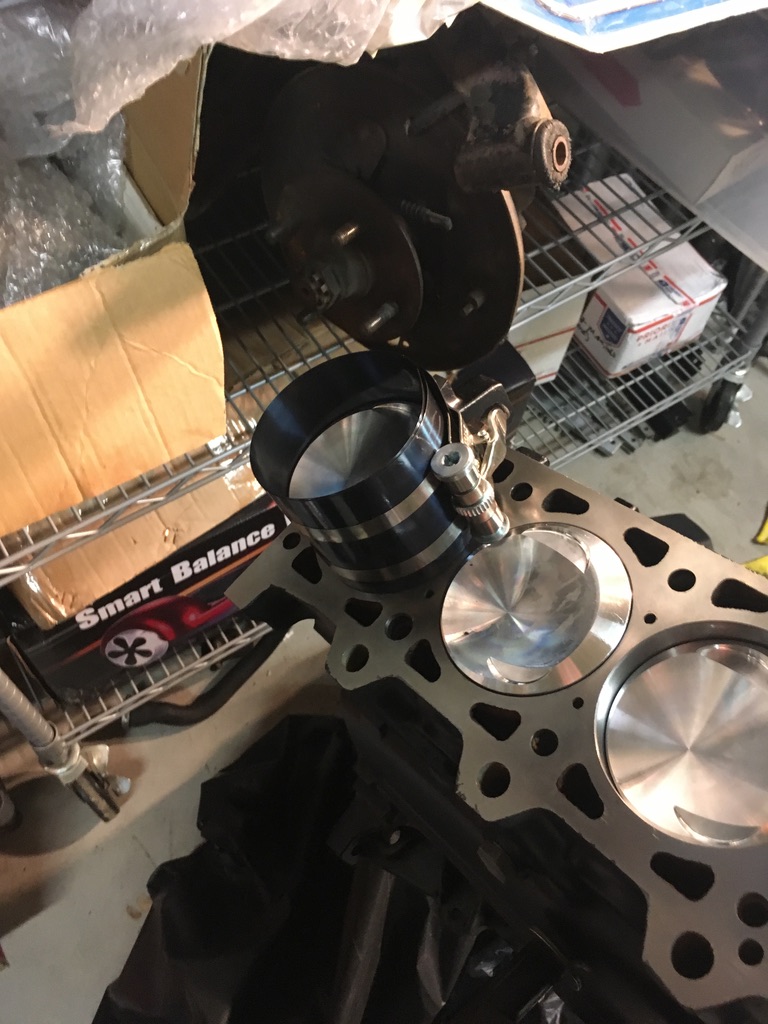

Then, on goes the ring compressor.

Then, on goes the ring compressor.

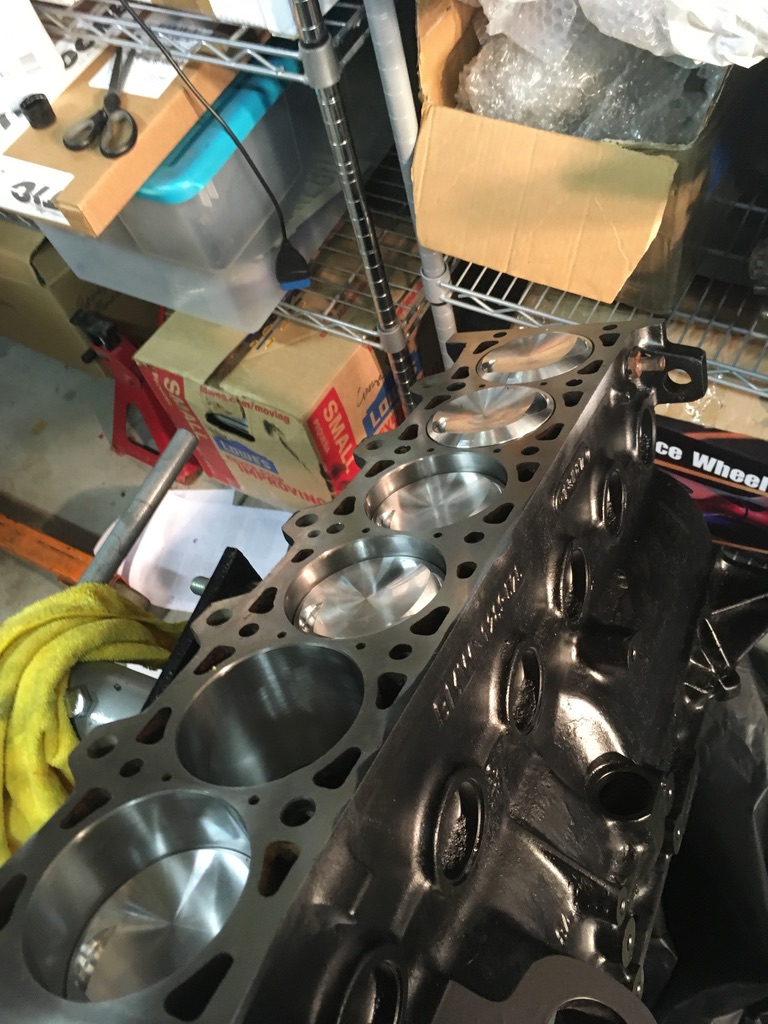

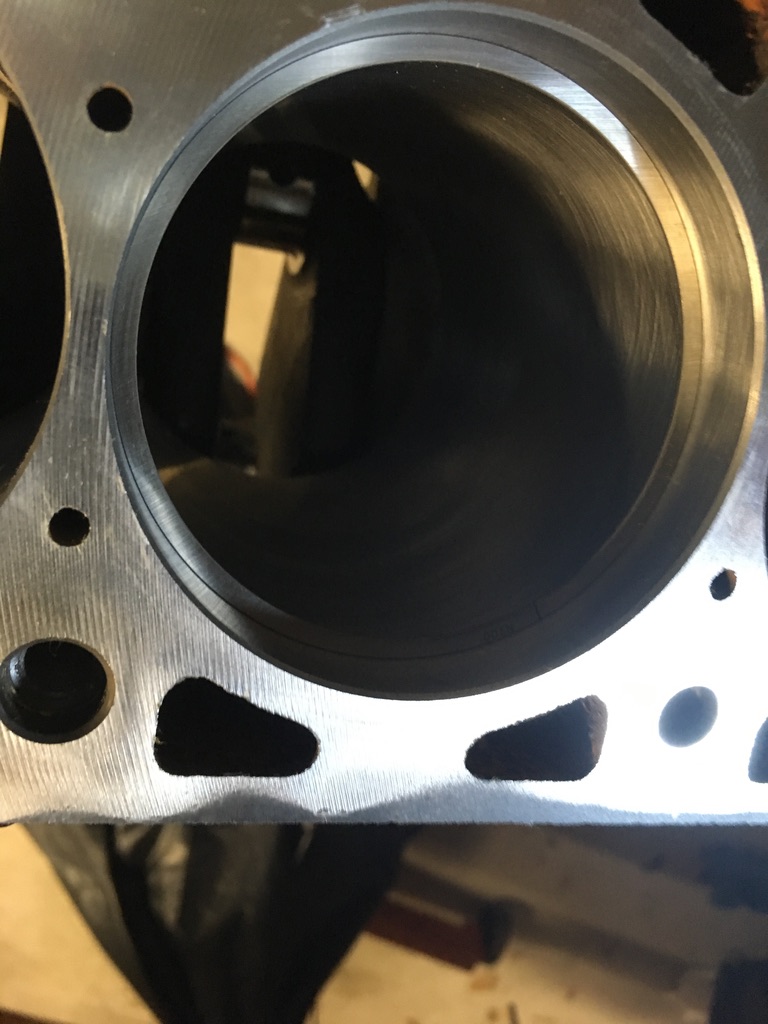

And placed in the block (with rod bearing installed and assembly lube applied. Also, make sure the crank journal for that cylinder is at the bottom of its stroke, so the con rod doesn’t ding it (don’t ask me how I learned that lesson!).

And placed in the block (with rod bearing installed and assembly lube applied. Also, make sure the crank journal for that cylinder is at the bottom of its stroke, so the con rod doesn’t ding it (don’t ask me how I learned that lesson!).

And placed in the block (with rod bearing installed and assembly lube applied. Also, make sure the crank journal for that cylinder is at the bottom of its stroke, so the con rod doesn’t ding it (don’t ask me how I learned that lesson!).

And placed in the block (with rod bearing installed and assembly lube applied. Also, make sure the crank journal for that cylinder is at the bottom of its stroke, so the con rod doesn’t ding it (don’t ask me how I learned that lesson!).

One at a time.

One at a time.

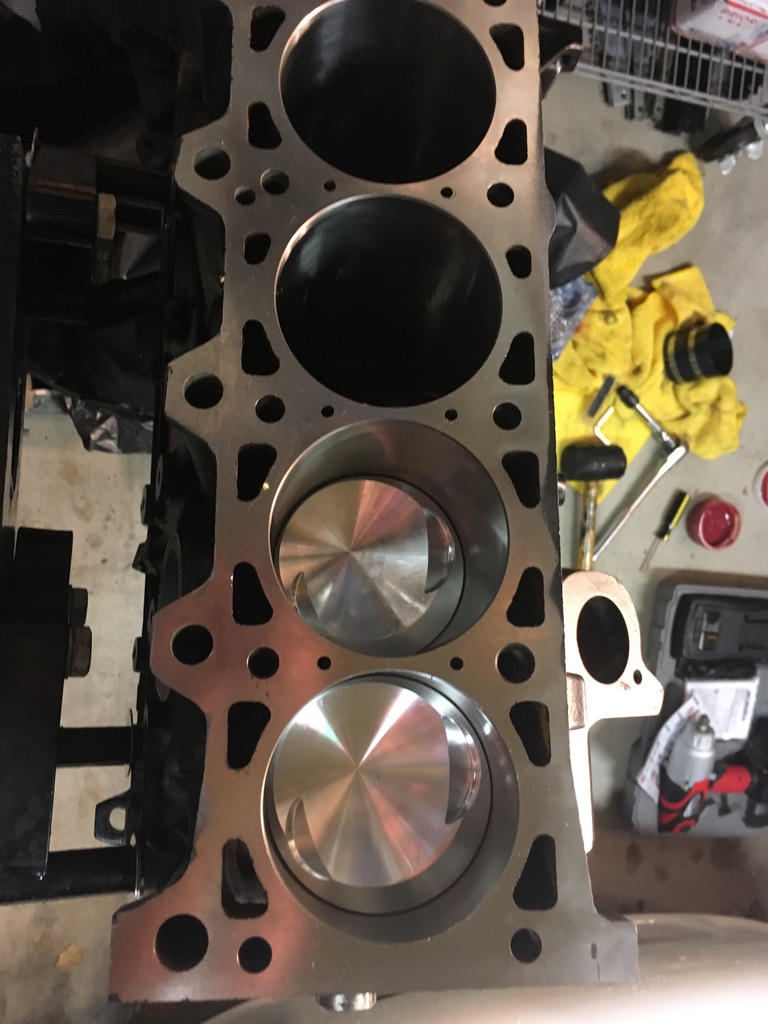

Eventually, all six are in.

Eventually, all six are in.

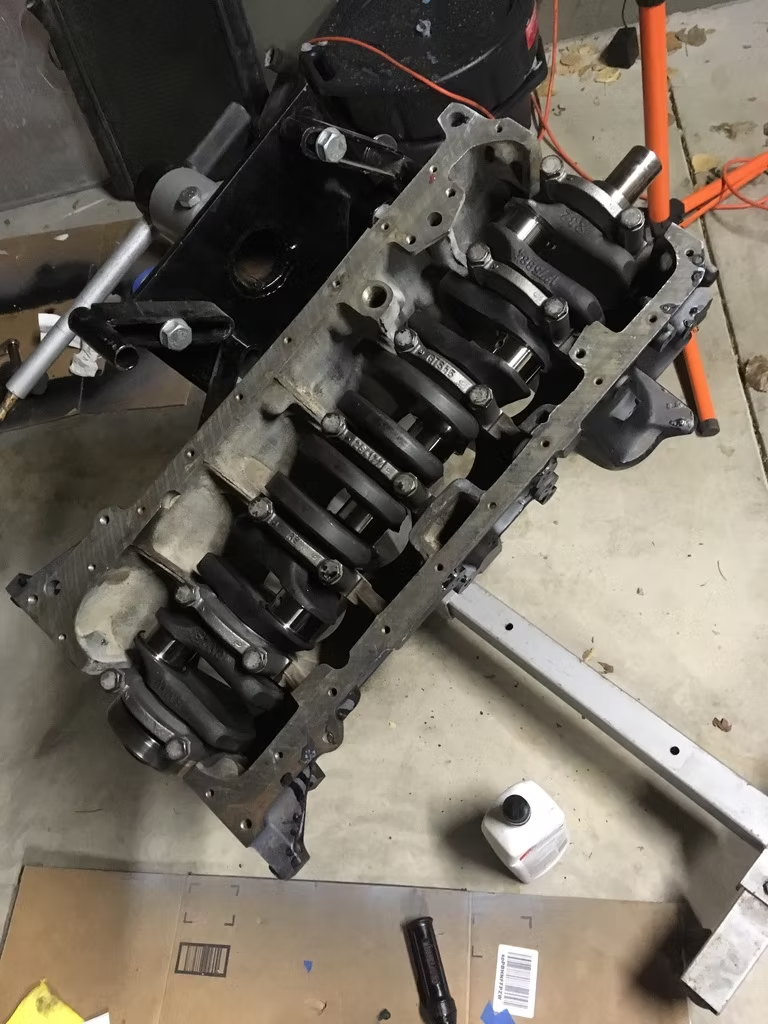

Torque the rod bolts.

Torque the rod bolts.

And if you’re lucky, it still turns.

And if you’re lucky, it still turns.

<Embedded video>

Meanwhile, the reassembly of the body has stalled, waiting for a new headliner. The head, too, is MIA, still at the machine shop waiting for “the end of the week.”

Up next: oil pump, flywheel and the head getting back for the machine shop and then mating it to the block.

Then I tried to figure out which way the end caps went (internet research helped as it wasn’t obvious from trying to fit them).

Then I tried to figure out which way the end caps went (internet research helped as it wasn’t obvious from trying to fit them). With the order and orientation of the end caps clarified, it was time to install the rod bearings in the block.

With the order and orientation of the end caps clarified, it was time to install the rod bearings in the block.

And the end caps.

And the end caps.

Then it was time for the turbo diesel crank.

Then it was time for the turbo diesel crank.

Gently place the crank in the block.

Gently place the crank in the block.

And install the end caps with bearings.

And install the end caps with bearings.

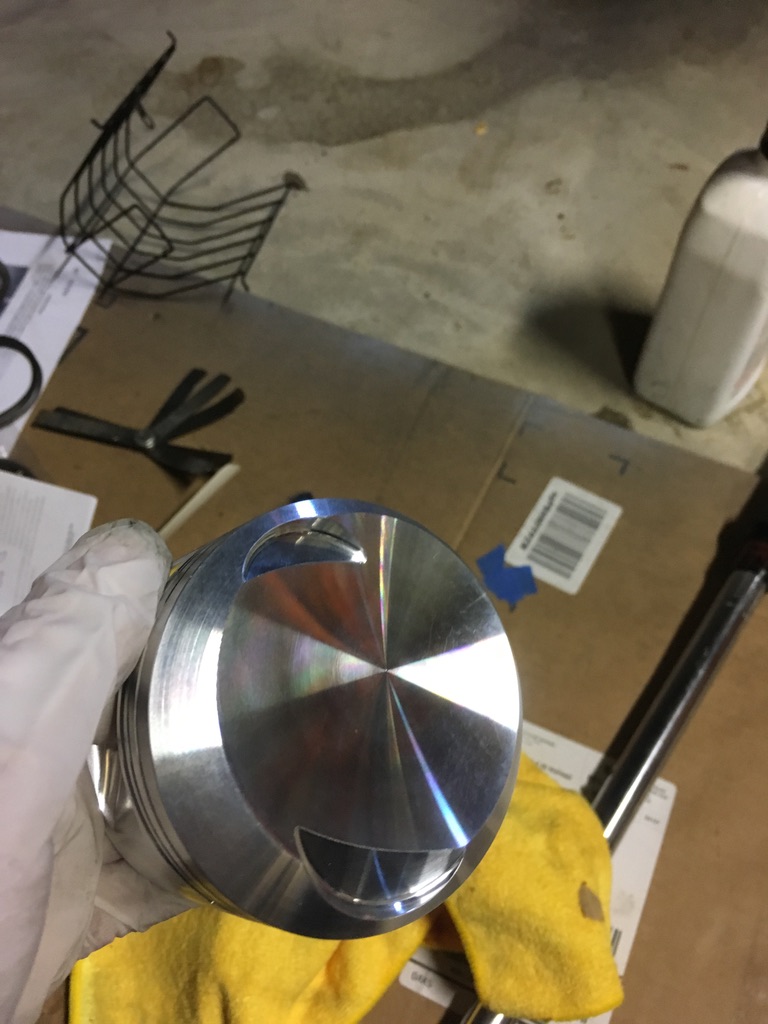

And install them on the pistons.

And install them on the pistons.

Then attach the rods to the pistons. The hardest part being, without the right tool, installing the wrist-pin retaining clips.

Then attach the rods to the pistons. The hardest part being, without the right tool, installing the wrist-pin retaining clips.

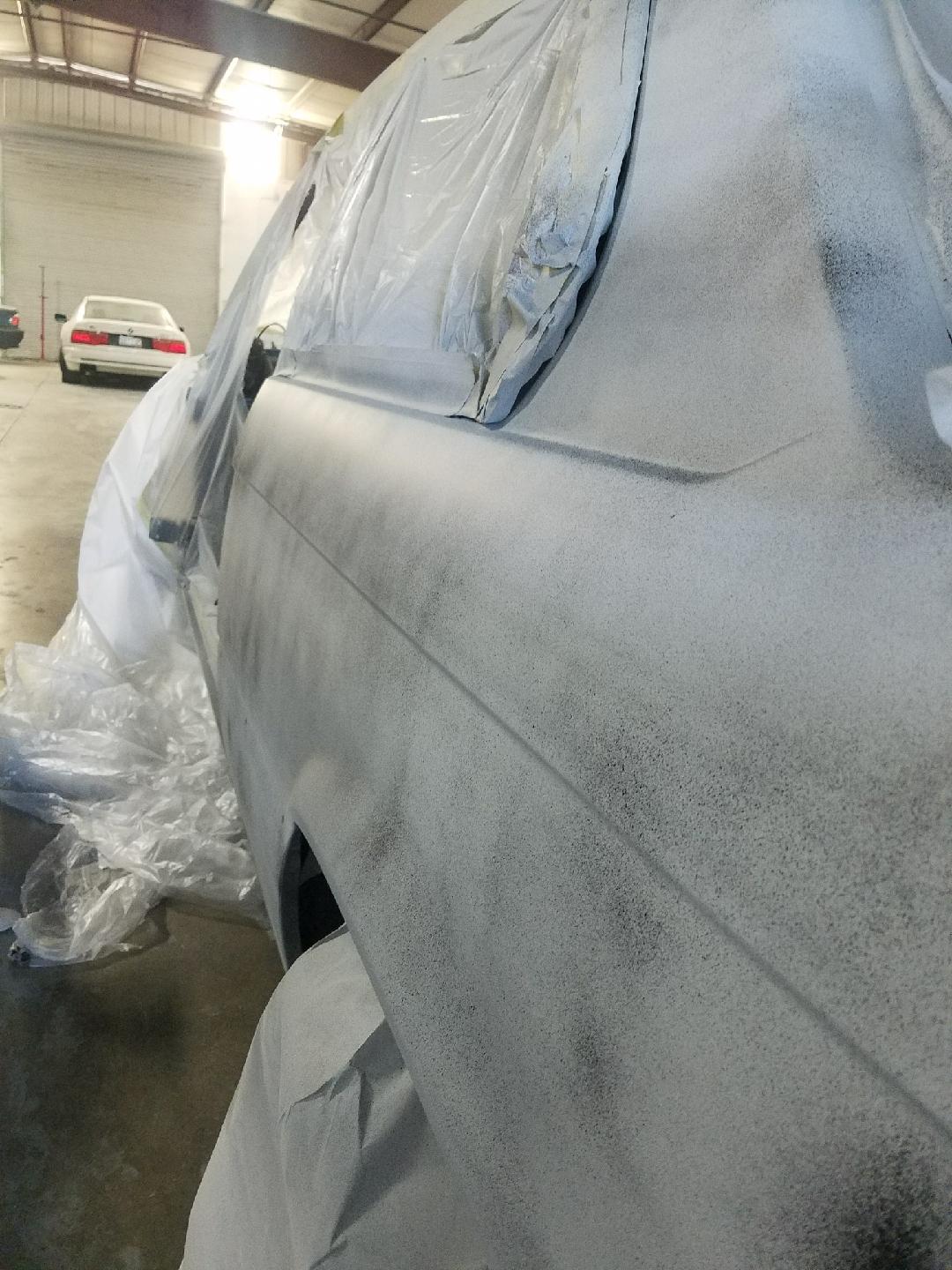

And then finally the shell, including the engine compartment, got painted.

And then finally the shell, including the engine compartment, got painted.

Next? The “new” dash and the glass will be installed and the body re-assembled. And with any luck, “tomorrow” may eventually come and the motor parts will be ready for me to begin assembling the motor.

Next? The “new” dash and the glass will be installed and the body re-assembled. And with any luck, “tomorrow” may eventually come and the motor parts will be ready for me to begin assembling the motor.

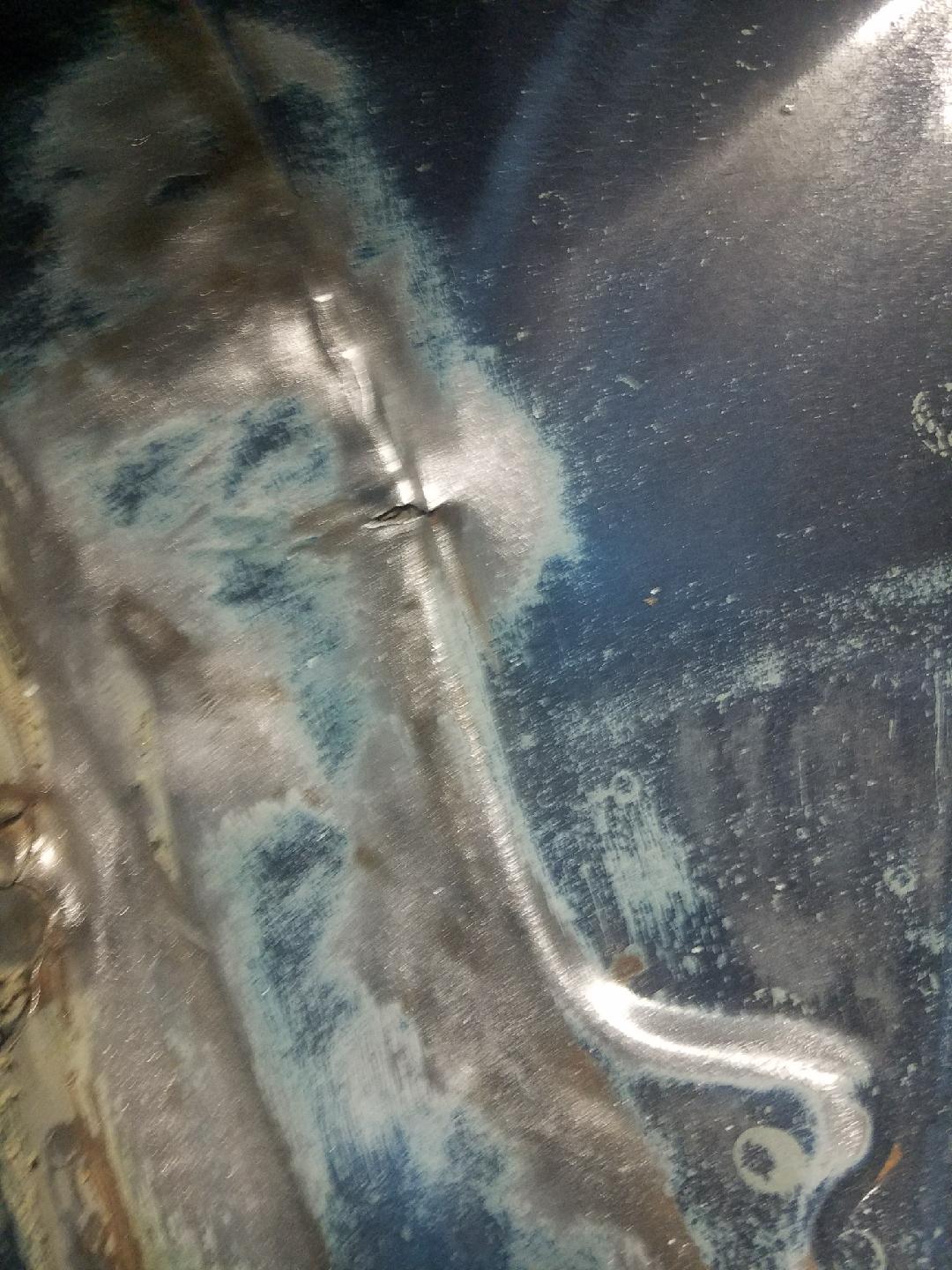

And welded up.

And welded up.

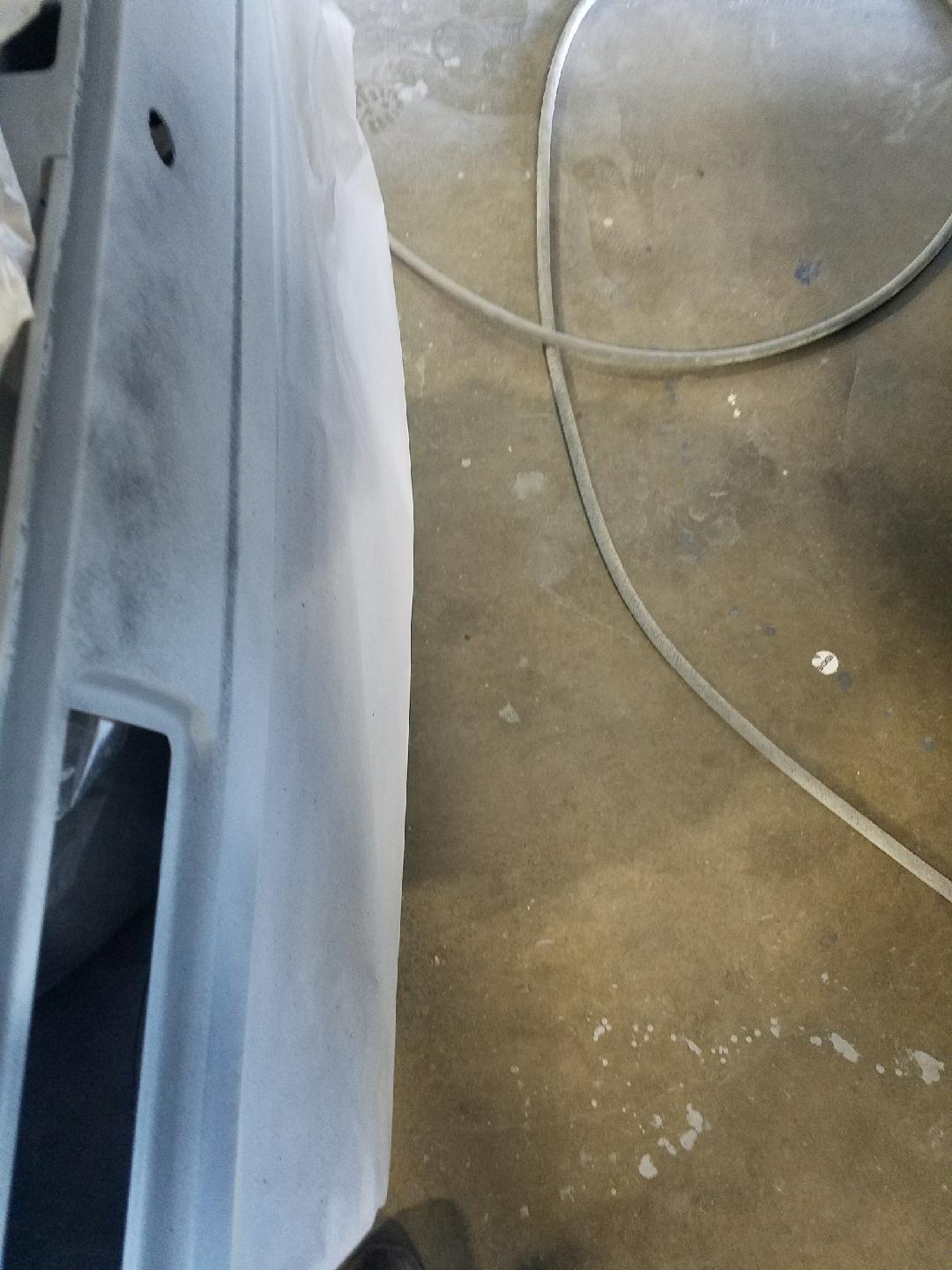

The front fender gets cleaned up, including plugging the holes for the USA sidemarker lights.

The front fender gets cleaned up, including plugging the holes for the USA sidemarker lights. Waves a long the rear fenders and roof are smoothed out.

Waves a long the rear fenders and roof are smoothed out.

And the air dam gets cleaned up as well.

And the air dam gets cleaned up as well. Next up: finish prepping for paint, prime it, and then paint it. The body work has good momentum, I sure hope the motor will start moving along.

Next up: finish prepping for paint, prime it, and then paint it. The body work has good momentum, I sure hope the motor will start moving along.

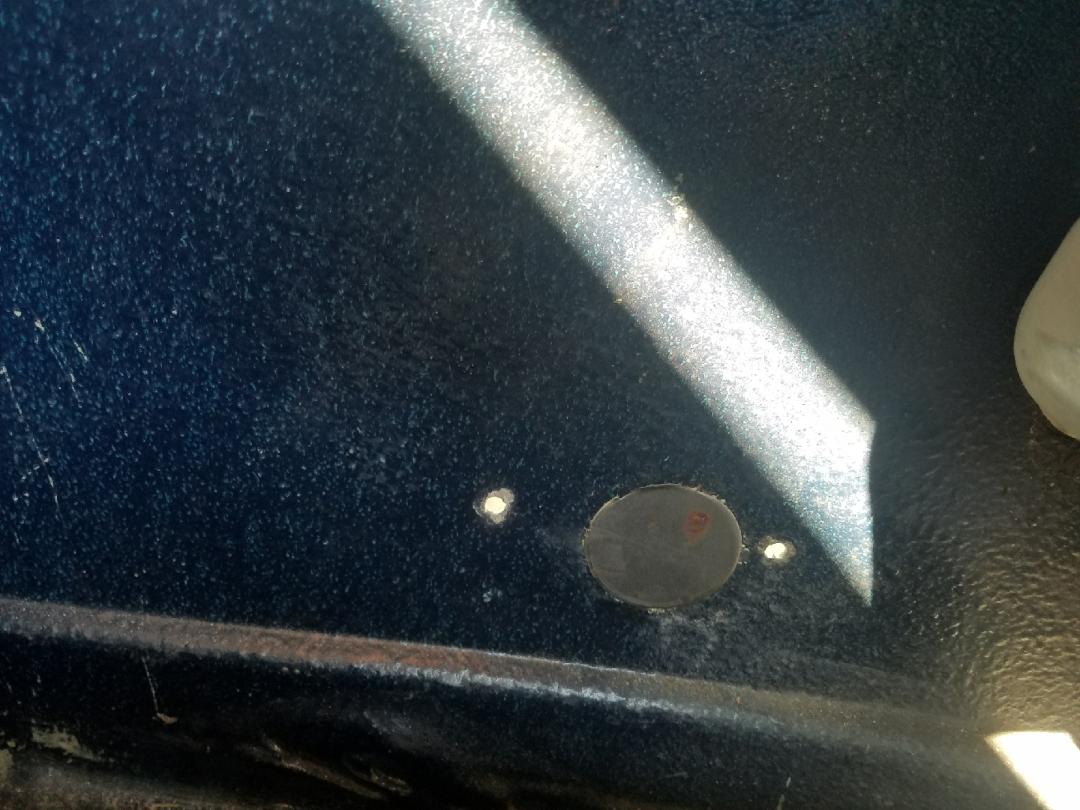

The shock towers had been drilled for a rear strut brace/battery holder that I removed (putting the battery back in the engine compartment).

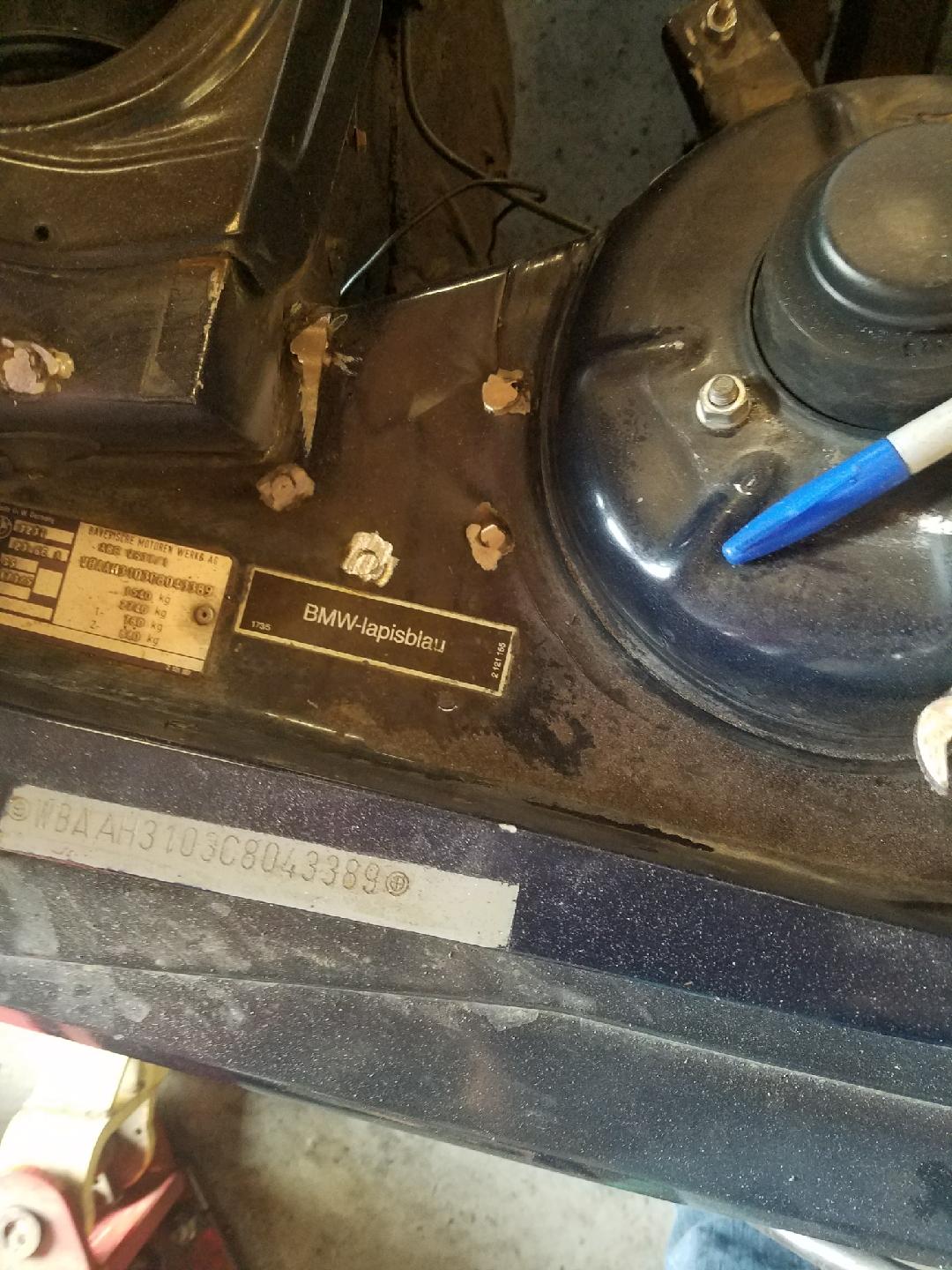

The shock towers had been drilled for a rear strut brace/battery holder that I removed (putting the battery back in the engine compartment). And there were weird holes drilled in various places, including in the engine compartment near the VIN plate; what those holes were for is another mystery (I thought it might be for an Alpina VIN plate, but it didn’t fit the spacing of the holes).

And there were weird holes drilled in various places, including in the engine compartment near the VIN plate; what those holes were for is another mystery (I thought it might be for an Alpina VIN plate, but it didn’t fit the spacing of the holes). Bits of rust – typical for a 1980s BMW, even one that spent it’s whole life in California – and other imperfections are taken care of.

Bits of rust – typical for a 1980s BMW, even one that spent it’s whole life in California – and other imperfections are taken care of.

The trunk lid and hood are taken off, prepped.

The trunk lid and hood are taken off, prepped.

And painted.

And painted. And then the whole body is stripped and prepped. And someday, painted.

And then the whole body is stripped and prepped. And someday, painted.

While all this was going on, I began delivering parts to the machine shop. The guy I’m using specializes in 4 and 6-cylinder air-cooled Porsche motors, but he is the shop used by one of the local vintage BMW specialty shops. I loaded much of the parts in my Porsche and brought both the forged M20 turbo-diesel crank and a bin of many other parts (custom pistons, clutch, forged rods, etc.), and the Schrick camshaft.

While all this was going on, I began delivering parts to the machine shop. The guy I’m using specializes in 4 and 6-cylinder air-cooled Porsche motors, but he is the shop used by one of the local vintage BMW specialty shops. I loaded much of the parts in my Porsche and brought both the forged M20 turbo-diesel crank and a bin of many other parts (custom pistons, clutch, forged rods, etc.), and the Schrick camshaft.

The block and head are already there, as is the intake manifold, which needs to be bored to match the bigger ports in the 325i “885” head.

The block and head are already there, as is the intake manifold, which needs to be bored to match the bigger ports in the 325i “885” head.