by alpinac1_pn9him | Apr 12, 2022 | Uncategorized

When I left you, dear reader, on New Years Eve 2021 the sunroof was being put together and I ticked off a list of things that still needed to be done to get the car back on the road. The list was significant – finish the engine electrical, populate the interior, including all the dash components, heater, console, and more – but comparatively short, given how long the list was when the pandemic started.

Since then the sunroof and hood have been installed and the car is ready to be trucked down from Sacramento to my garage in the San Francisco Bay Area, some 100 or so miles. Just for a little perspective, the picture below is from October 2017 when Stu came down with his truck and trailer to take the motorless shell up to Sacramento for the paint job.

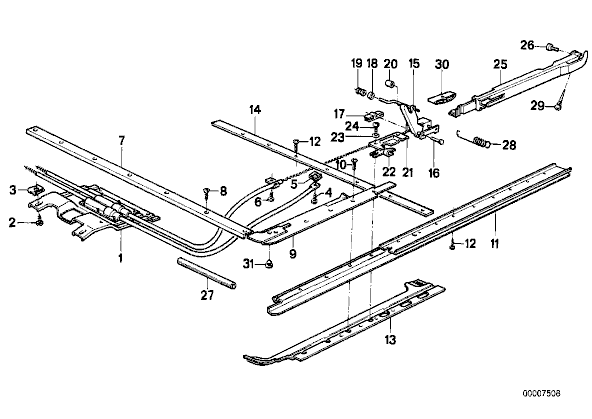

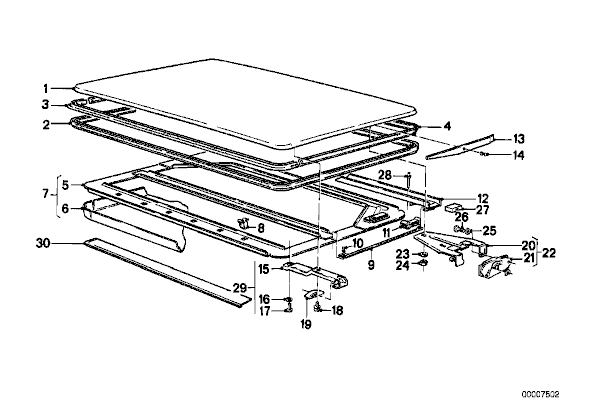

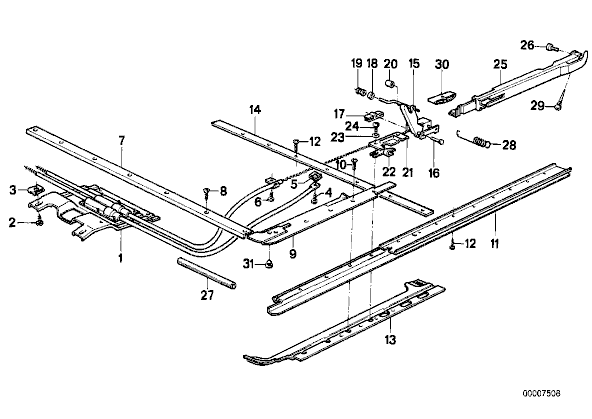

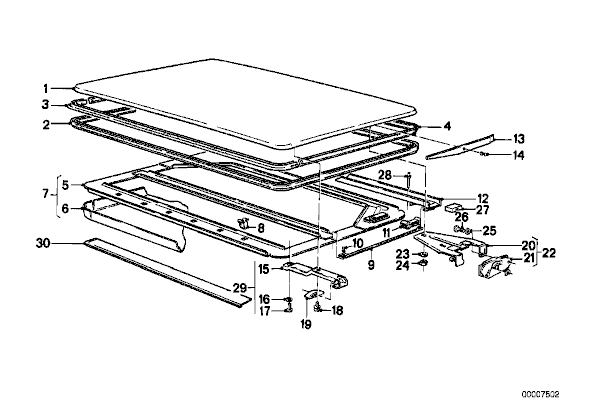

Getting the sunroof back in was not easy. The entire mechanics were disassembled and most of the little parts did not stay with the shell when the body shop closed. Sourcing those small but necessary parts takes time and ingenuity. Some parts were available from BMW, some were on eBay new or used, some we got from a junk yard with an old 6-series (thankfully BMW used the same parts in several different platforms). That took many trips up to Sacramento to install the parts I got and figure out the ones I needed to get. Slow and frustrating progress.

Getting the sunroof back in was not easy. The entire mechanics were disassembled and most of the little parts did not stay with the shell when the body shop closed. Sourcing those small but necessary parts takes time and ingenuity. Some parts were available from BMW, some were on eBay new or used, some we got from a junk yard with an old 6-series (thankfully BMW used the same parts in several different platforms). That took many trips up to Sacramento to install the parts I got and figure out the ones I needed to get. Slow and frustrating progress.

Above I told you the sunroof was in. And that is true. But it was a misleading but factual statement (my lawyer training coming through!). We finally got all the parts and were able to put the sunroof in the car. But we couldn’t get it operating. Or at least fully operating. The tilt works but not the back and forth. I’m sure with time and energy it will work but I was up for two days and had other things to accomplish before leaving. Plus, I really don’t like sunroofs anyway, so having it in but not working is not anything even near a hardship for me. Finally, the sunroof and the hood were the two final steps in getting the car water tight so it could be trucked back home.

Above I told you the sunroof was in. And that is true. But it was a misleading but factual statement (my lawyer training coming through!). We finally got all the parts and were able to put the sunroof in the car. But we couldn’t get it operating. Or at least fully operating. The tilt works but not the back and forth. I’m sure with time and energy it will work but I was up for two days and had other things to accomplish before leaving. Plus, I really don’t like sunroofs anyway, so having it in but not working is not anything even near a hardship for me. Finally, the sunroof and the hood were the two final steps in getting the car water tight so it could be trucked back home.

I was working on the hood also the day we got the sunroof in. As with the sunroof, the hood was disassembled for paint and many of the little parts were missing. I was able to find most new or on eBay but they were primered, not painted. So I got some rattle cans from paintscratch.com and painted them in between the sunroof installation. By the next morning all the parts were ready to be put in the hood. By happenstance an e21 was in the shop for me to use as a template; I’d look at the white car there and go back to my hood and install parts over and over. Soon three of us carried the hood over to the shell to reunite them. Bolting it on was straight-forward but took some time. The tensioners are not on right I suspect, as the hood won’t stay up on it’s own. But the car is water tight and ready to come home.

Now we just need to find a time when I’m in town and Stu can truck it down. Once it is back in my garage I’ll populate the interior and wire up the few remaining electrical items and figure out what else is left unfinished. Oh, and see about getting the sunroof operational and the hood staying in open position.

by alpinac1_pn9him | Dec 31, 2021 | Uncategorized

The title for this post was going to be A New Year, given that I sat down to write this on the morning of New Years Eve, 2021. But that title was taken by a 4-year-old post discussing the paint—an event so long ago I forgot the title had been used already. Yes, a lot of time has gone by but, besides retiring from my day job, my daughter graduating college, a global pandemic, and my son going off to college, it feels like not much has happened. Ok, I guess a lot has happened. Just not to the car, that is.

That theme—that life continues to move forward but the car doesn’t really—is both true and false. It’s been a good six months since my last post, enough time to complete the car. Of course that hasn’t happened and the progress that has been made doesn’t feel like half a year’s worth.

In that six months I’ve driven across the country twice, once by myself in a 1992 BMW M5 wagon I bought to replace my daily driver and then a second time with my daughter and her dog, bringing them home for the holidays. Both trips were fun but I would have preferred not have hit the deer and totaled the X3 that my daughter and I were taking across the country.

The M5 wagon in Utah

The totaled X3

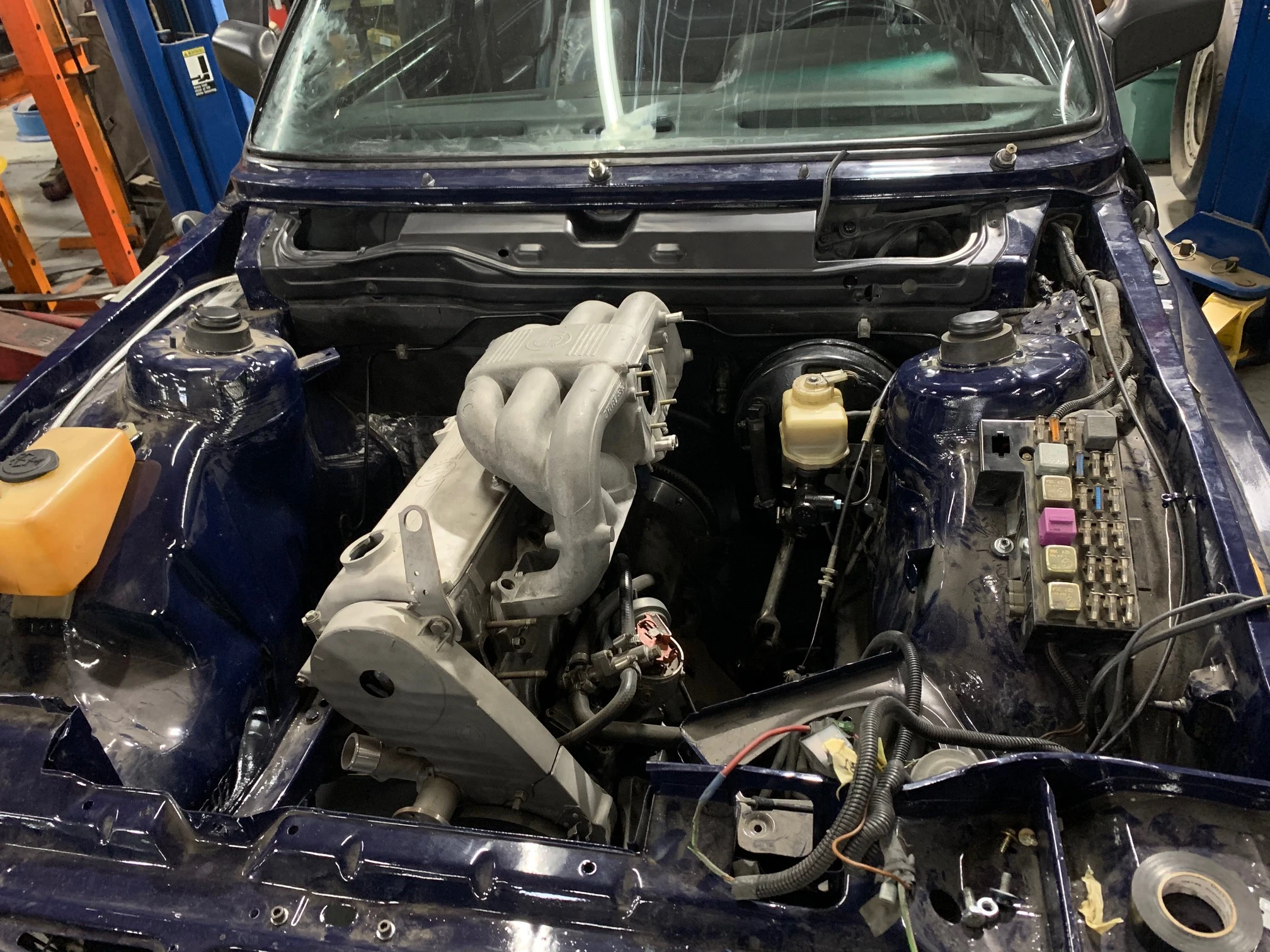

Once back from my travels, I made my way up to Sacramento to work on the car. The motor is almost done. Fuel injection was populated. Headers bolted up. Cooling system—radiator and hoses—installed.

Rear windows put in and parts for door trim being sourced from around the world.

Rear windows put in and parts for door trim being sourced from around the world.

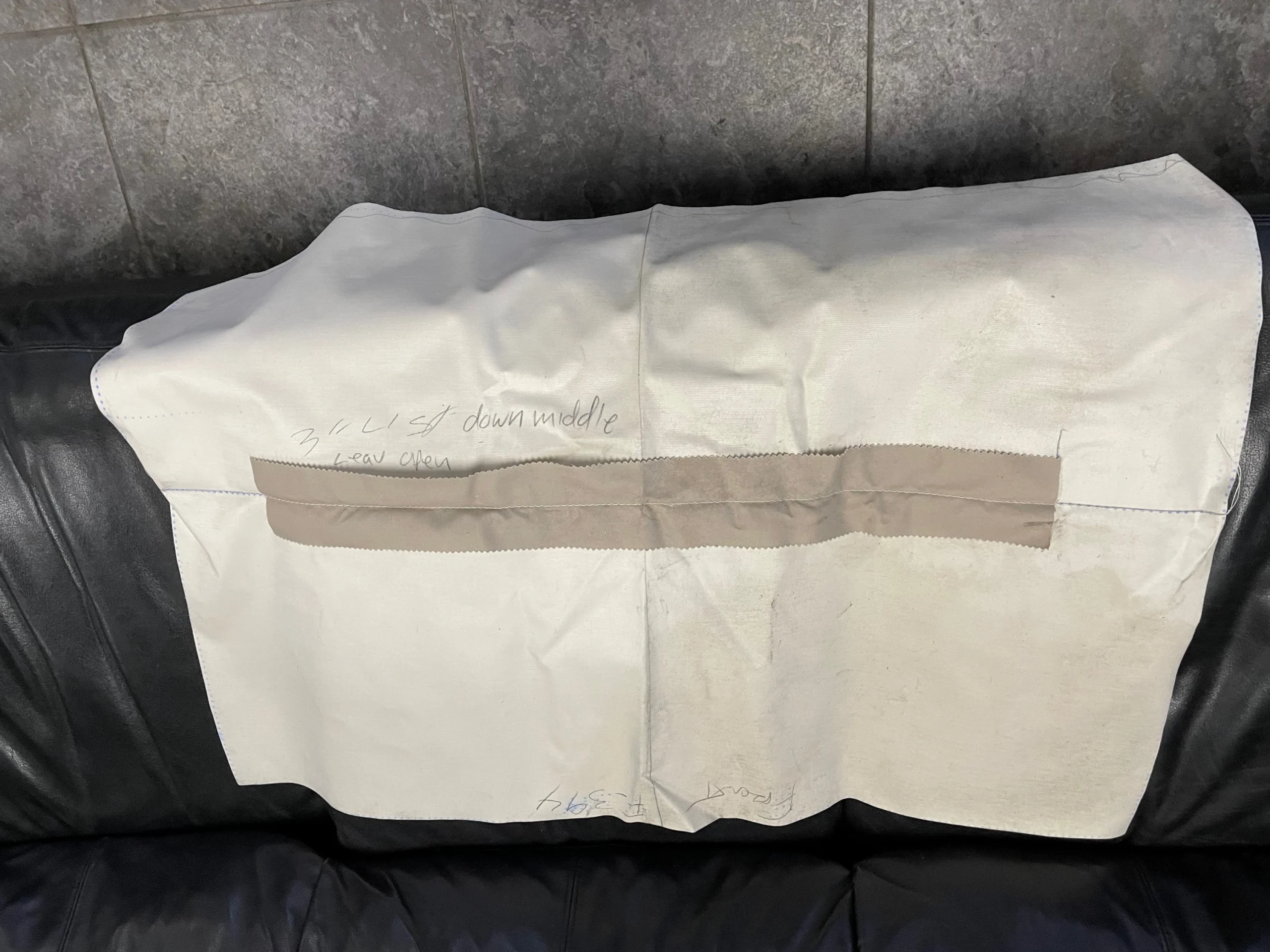

And, most recently, the sunroof is finally being addressed. First was cleaning up the sunroof frame and installing the headliner on it. Next up will be reinstalling the sunroof mechanics, the headliner frame and then the roof itself. That may happened next week.

And, most recently, the sunroof is finally being addressed. First was cleaning up the sunroof frame and installing the headliner on it. Next up will be reinstalling the sunroof mechanics, the headliner frame and then the roof itself. That may happened next week.

by alpinac1_pn9him | May 4, 2021 | Uncategorized

A lot has happened since the last post in early December. At the same time, it feels like the project bounced around with little coming to completion. During the hour and a half drive up to Sacramento I’d often review the progress in my mind and wonder if it was time for a new post. But there was no arc to a story; plenty was being done, progress was (slowly) being made. But none of the things I’d been working on were completed—the stories had beginnings, some had middles, but no end. And that, I realized, is the story.

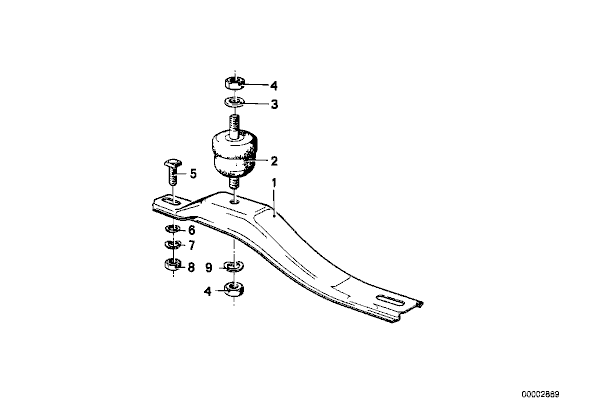

Ok, that’s not completely true. There have been a few things that have been completed. The transmission is in and the rest of the drivetrain buttoned up. Some pesky rust was found on the frame rail, ground out and plates welded in to cover the holes and ensure structural integrity. Yet much of the car—the fuel injection, the cooling system, the interior—is still a work in progress, and progress has been slow. And, little by little, it keeps moving forward.

The reoccurring theme with the car, at least in this drive-up-to-Sacramento phase, has been the trying to put together a car that someone else took apart years ago. The transmission exemplifies it: After the motor was dropped in, the transmission was put in—we put the car up high on the lift and lifted in the transmission by hand and stabbed it in the clutch. Once bolted in we realized that we had the wrong rear support bracket (it was from a 5-series) but the transmission was hanging there unsupported; we needed something to hold it up while sourcing the right part. I flipped over the 5-series bracket, which caught a corner of the transmission, barely holding it in place until we got the right part. That took a few weeks: the bracket was NLA and when I found a used one it took awhile to get shipped to my home; it was in the car on my next trip up to the shop.

But eventually, the right support bracket was sourced and in the car, followed by a guibo and the shift linkage, clutch slave and a whole bunch of little things, resulting in a completed drivetrain. That was the good news from under the car.

The bad news was I noticed bubbling on driver’s side frame rail. I poked it and it was crumbly, a sure sign it was rust. A couple of hours with the Dremel tool and I had 3 holes in the frame rail ranging in size from a dime to a quarter or maybe even a half-dollar. After grinding out all the rust, the metal was treated. We cut some plates from steel sheet metal and Stu welded them in over the holes. I ground down the welds and primed it.

The plates being held in by tape, ready to weld

The welds ground down and the plates primed

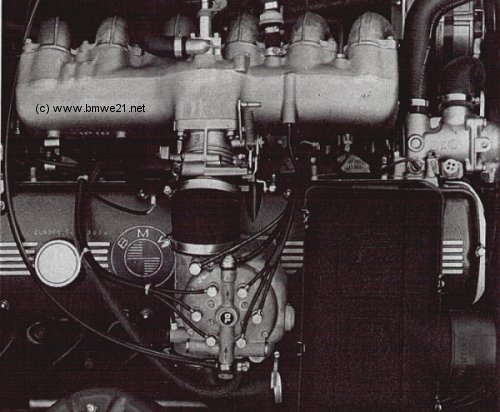

Meanwhile, with the engine in, I started to populate it. First was the wiring, then the fuel injection. For the wiring, I asked a few folks on the FaceBook e21 page for pictures of the routing of the wiring; using those as guides, I laid out the wiring harness and connected the electrical components. That was relatively easy.

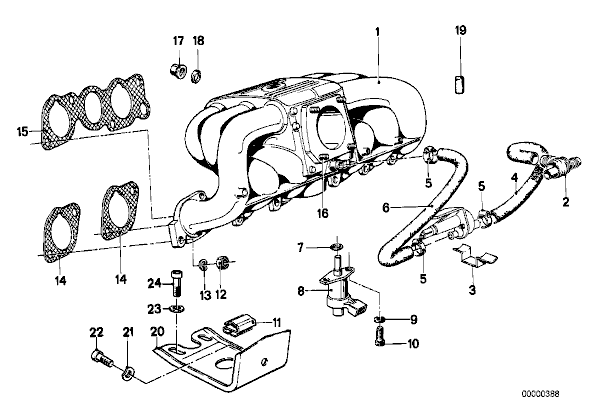

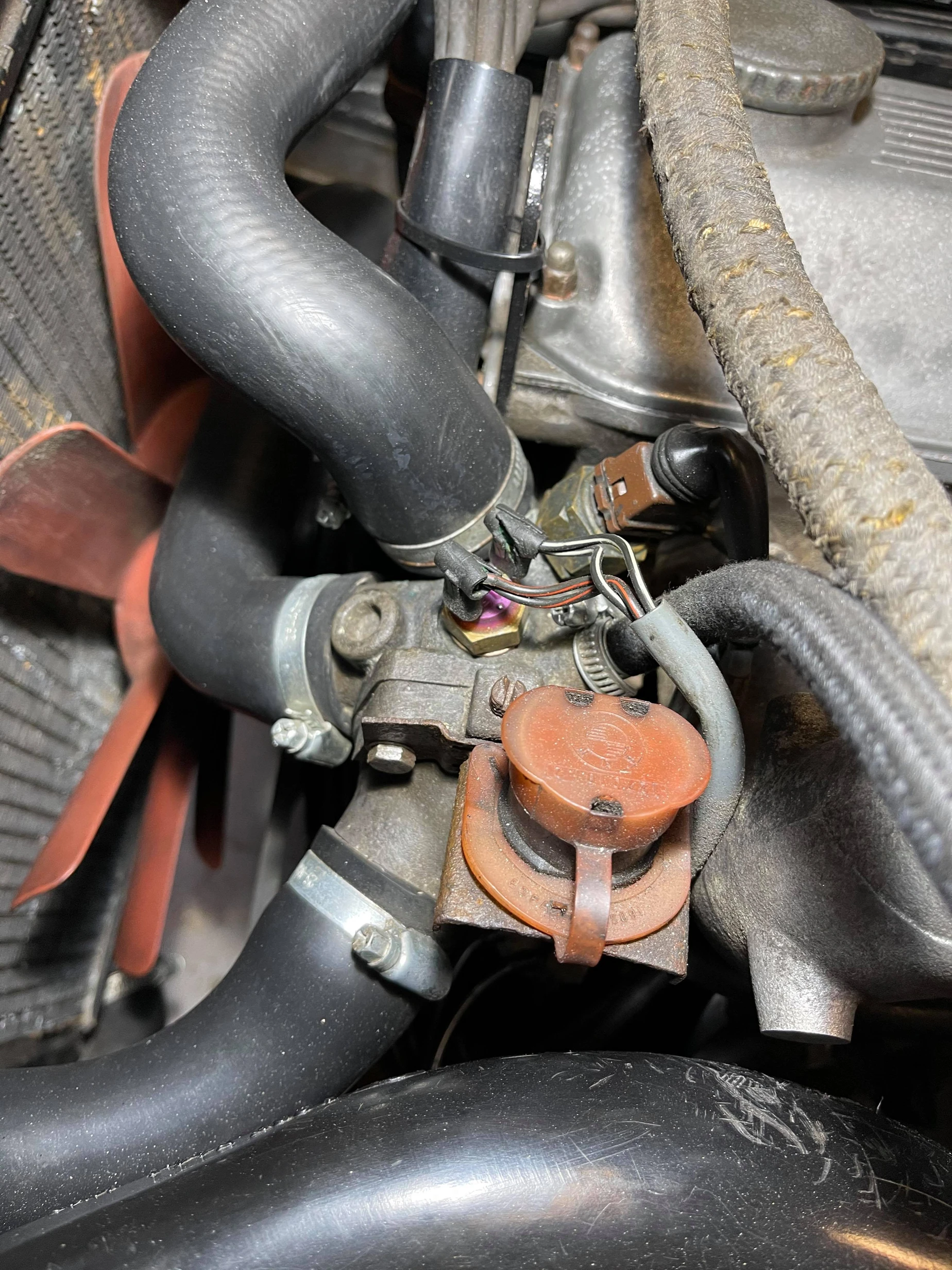

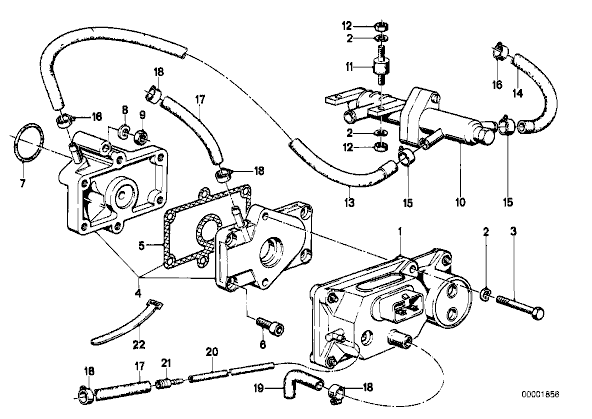

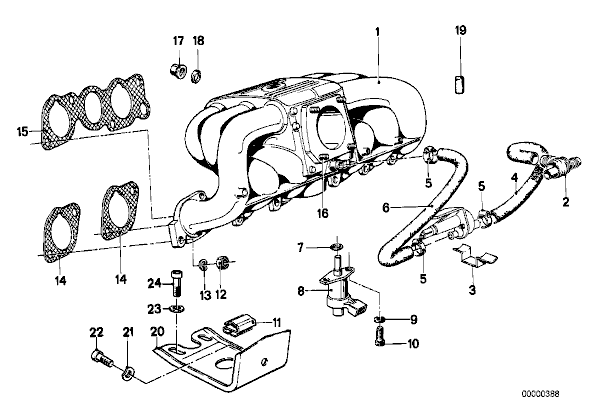

The fuel injection was more challenging. The basics of the Bosch K were easy enough but it wasn’t time for that yet. Figuring out the auxiliary air system was not so simple. I had too many parts and not enough space to fit it all. I consulted the parts pictures on Mobile Tradition website, which showed two different auxiliary air systems, one using electricity to heat it and another heated by the coolant. And I had parts for both. The parts catalog did not present it as an either-or situation and I spent a fair amount of time trying to figure out how the two systems worked together. I also wondered why would BMW have both systems in one car?

After consulting with other e21 323i owners, it became clear I was right to question both systems working in tandem; it was either-or and that my car used the coolant-based system when I tore it apart years ago. Later, I figured out that the second system was from the spare intake manifold I had. I could have used either but decided to stick with what the car came with, even though it was more complicated. (An interesting side-note: both systems used coolant as a warming agent on the intake system. The system I call coolant based system has coolant run under the fuel pressure regulator (in pic below) and then to the auxiliary air valve. The so-called electrical system uses an electronically warmed auxiliary air valve but runs coolant through the throttle body, I guess to warm the air as it goes into the intake manifold. Why they wanted to do that, I don’t know!)

The electrical system

The extra intake manifold with the electric auxiliary air valve

Once I knew which system I wanted to use, I needed to figure out the routing of the hoses. With that done, it was simply a matter of attaching the hoses and bolting the actual valve to the underside of the manifold. Of course, I wanted to replace worn hoses—and was both easy and difficult. It’s easy to attach new hoses and to source standard sized ones that don’t have weird twist and turns in them. But some were special order parts, further delaying progress because the only way to get them was from Walloth and Nesch in Germany. For some inexplicable “reason” BMW has a schizophrenic policy on US vendors selling euro-only parts. Some euro-only parts can be sourced by US vendors without any drama, but for others you have to show a registration proving you own such a car—and sometimes after doing that BMW still won’t allow them to be sold here. When that happens, the parts have to be ordered from German suppliers or foreign eBay vendors. If I can’t find the parts on eBay, Walloth and Nesch is often the solution, but given their 49 euro shipping charge, I try to bundle parts into a single order, causing even more delays.

The auxiliary air system installed

Planning ahead—and bundling parts orders—has been a challenge for me, given my myopic approach of simply attacking what is in front of me. I’ve been trying to teach myself to think ahead and, in that vein, I realized I’d need to put in the headers soon. The car had came with SuperSprint headers but they were old and rusty.

So, I took them to a header shop and had them welded up and ceramic coated. They look great now. It was nice, too, to do this in advance of actually needing them and not delaying the project while they were getting restored. Score one for the home team!

A bunch of little tasks have been completed, too. For example, the door panels are back on, with the handles, cranks, and arm rests (which were found in the strangest places in the shop). A new radiator and coolant overflow were ordered from Walloth and Nesch; including the 49 euro shipping, they were over $100 cheaper than a US vendor, believe it or not!

The exhaust was just hanging there, without the “doughnut” supports.

Five minutes later (after a week of waiting for the part), it was done. Were it was all that easy!

We all knew that eventually the fuel injection would be installed on the engine and that day finally came. Because of the modifications to the motor, the stock fuel injection wasn’t going to keep up with the fuel demands of the mild cam increase and significant extra displacement. So I Frankensteined together a bunch of Bosch K parts that Porsche used on the 2.7 liter euro 911S; that motor put out about 210 horsepower, so it flowed enough fuel for my motor. I also arrived at these parts in consultation with another C1 2.3 owner who built a similar motor.

Because the parts were Frankensteined together, I did a test fit (which I didn’t quiet finish yet). But first I had to clean up the remaining parts that I was using. The air box got cleaned and painted. The support base that connects the air flow sensor to the air box went into the media blaster to get cleaned up too.

The support bracket before getting blasted.

The support bracket cleaned and on half of the air box

Bolting the air flow sensor on was straight-forward

Before going further, those components needed to be test-fitted. I also needed to figure out what other parts were necessary to install the fuel injection. A couple more things were ordered and the car put away until they arrive.

After every session, the car has to be raised up and a very, very dusty e30 M3 is tucked in underneath. Good company!

Alas, the list of things to be done is still long: finish the fuel injection, figure out how to wire in the coil, install the headers, finish the headliner, install the sunroof, populate the dash (gauges, heater controls, etc.) that was disassembled when it was sent to Just Dashes to repair the cracks. Once that is done, it can be fired up and see if the damn thing even runs. Feels like that is months away. My goal was to drive the car to Monterey this August for car week. It feels like that is slipping further and further into the unlikely category….

by alpinac1_pn9him | Dec 20, 2020 | Uncategorized

A little over a month ago there was the first progress update in two years. Because of the pandemic I had the time to go up to Sacramento regularly and get moving the project along; Stu welcomed this because he didn’t have time to do it yet wanted to see things go forward. The goal was for me to go up at least once a week, which I’ve been able to do since the last post.

Reassembly presents a strange dichotomy. It is sometimes simultaneously enthralling and frustrating. It is enthralling to reassemble a car that was touched by the hands of God, the Alpina factory, seeing what they did—both sophisticated and, occasionally, somewhat primitive.

But the challenge of finding the parts to reassemble the car is frustrating. The disassembly was haphazard and parts show up in the strangest places in the shop, others missing or found after I’ve ordered new ones. At times it seems I’m spending more time searching the internet for little bits here and there than reassembling the car. On top of that, some of the parts I collected 4 years ago turned out to be the wrong ones (and can’t be returned now) or are just missing. On top of that, there’s the steep learning curve of trying to assemble a car you didn’t take apart.

The door locks are great example. They were taken out for painting and the original gaskets were nowhere to be found—probably they deteriorated and were not reusable—and new ones needed to be ordered. New ones were sourced from a local BMW dealer, but they didn’t work—they were round without indents to follow the contours of the lock body. Although the right part number, BMW apparently has consolidated those gaskets with ones from other cars and the “right” part (according to BMW) didn’t fit my car. A search on eBay found the New Old Stock ones that would work but they were in Greece (gotta love the internet!). The vendor had great feedback and several other BMW parts for sale so I clicked buy.

Four weeks later DHL delivered the gaskets and I finally had everything needed to put in the door locks. Getting the lock cylinder into the door was a trick, at least for someone like me who has never done it before. I started with the passenger side. The cylinder seemingly did not fit into the hole in the door; after fruitlessly trying to wiggling it in, I got more and more forceful, pushing it and then finally I held it centered on the hole and hit it with the palm of my hand. It barely went in and fell out as soon as I touched it. But, progress (however slight). A small hammer and gentle taps and it was in, but not by much—maybe a quarter-inch. Hit it a little harder and it went further in. Even harder and it was halfway in. Consistent gentle taps slowly morphed into firmer hits and it was getting closer and closer; it took a mere half an hour to get it firmly planted in the door. Learning how hard I could hit it took time; the fit was so tight it needed some serious force but I didn’t want to wack it too hard and damage the door. Then it took me 15 minutes to figure out how to attach little arm on the back of the cylinder to the lock; adding to the frustration was working in a tight space with no good line-of-sight. But, I figured out what parts of the door innards to disassemble to get room and sight; once I did, it was an easy job. The passenger side took 45 minutes (most of that being the learning curve), but the second one was finished in less than ten minutes. Knowledge is a powerful tool!

Four weeks later DHL delivered the gaskets and I finally had everything needed to put in the door locks. Getting the lock cylinder into the door was a trick, at least for someone like me who has never done it before. I started with the passenger side. The cylinder seemingly did not fit into the hole in the door; after fruitlessly trying to wiggling it in, I got more and more forceful, pushing it and then finally I held it centered on the hole and hit it with the palm of my hand. It barely went in and fell out as soon as I touched it. But, progress (however slight). A small hammer and gentle taps and it was in, but not by much—maybe a quarter-inch. Hit it a little harder and it went further in. Even harder and it was halfway in. Consistent gentle taps slowly morphed into firmer hits and it was getting closer and closer; it took a mere half an hour to get it firmly planted in the door. Learning how hard I could hit it took time; the fit was so tight it needed some serious force but I didn’t want to wack it too hard and damage the door. Then it took me 15 minutes to figure out how to attach little arm on the back of the cylinder to the lock; adding to the frustration was working in a tight space with no good line-of-sight. But, I figured out what parts of the door innards to disassemble to get room and sight; once I did, it was an easy job. The passenger side took 45 minutes (most of that being the learning curve), but the second one was finished in less than ten minutes. Knowledge is a powerful tool!

Another challenge was figuring out how the bundle of wires was supposed to routed through the engine compartment. I looked at the harness, which had an ugly re-wrap in electrical tape, and it was not at all apparent how to get from the fusebox to the headlights and horns. I inquired on the FaceBook e21 group and I found someone who restored a similar C1 2.3 (really, any e21 would have been fine, but it was great to find someone who did such a great job and documented it with photos). He sent pictures of his wiring and I was in business. I re-wrapped the harness in friction tape and routed it through the engine compartment.

Another challenge was figuring out how the bundle of wires was supposed to routed through the engine compartment. I looked at the harness, which had an ugly re-wrap in electrical tape, and it was not at all apparent how to get from the fusebox to the headlights and horns. I inquired on the FaceBook e21 group and I found someone who restored a similar C1 2.3 (really, any e21 would have been fine, but it was great to find someone who did such a great job and documented it with photos). He sent pictures of his wiring and I was in business. I re-wrapped the harness in friction tape and routed it through the engine compartment.

Then I installed the horns and lights and then grills.

Then I installed the horns and lights and then grills.

Then air dam. And talk about collecting dust! It looked like it had been painted some weird animal print pattern, but I washed it and it was good to go.

Then air dam. And talk about collecting dust! It looked like it had been painted some weird animal print pattern, but I washed it and it was good to go.

Putting the air dam on the car was one of the interesting archaeological parts of the restoration. The air dam has brake cooling ducts but behind the ducts on a stock body is the lower valance. So the boys at Buchloe cut a rectangle out of the valance to allow the air to flow to the brakes. Those cuts were uneven and kind of primitive. Honestly, they looked like something I would do in my garage!

Putting the air dam on the car was one of the interesting archaeological parts of the restoration. The air dam has brake cooling ducts but behind the ducts on a stock body is the lower valance. So the boys at Buchloe cut a rectangle out of the valance to allow the air to flow to the brakes. Those cuts were uneven and kind of primitive. Honestly, they looked like something I would do in my garage!

And sometimes it’s just fun cleaning things up and making them look spiffy; the hood latches were old and rusty, so into the media blaster they went. Quickly they were cleaned up and sprayed with lacquer. A serious improvement.

And sometimes it’s just fun cleaning things up and making them look spiffy; the hood latches were old and rusty, so into the media blaster they went. Quickly they were cleaned up and sprayed with lacquer. A serious improvement.

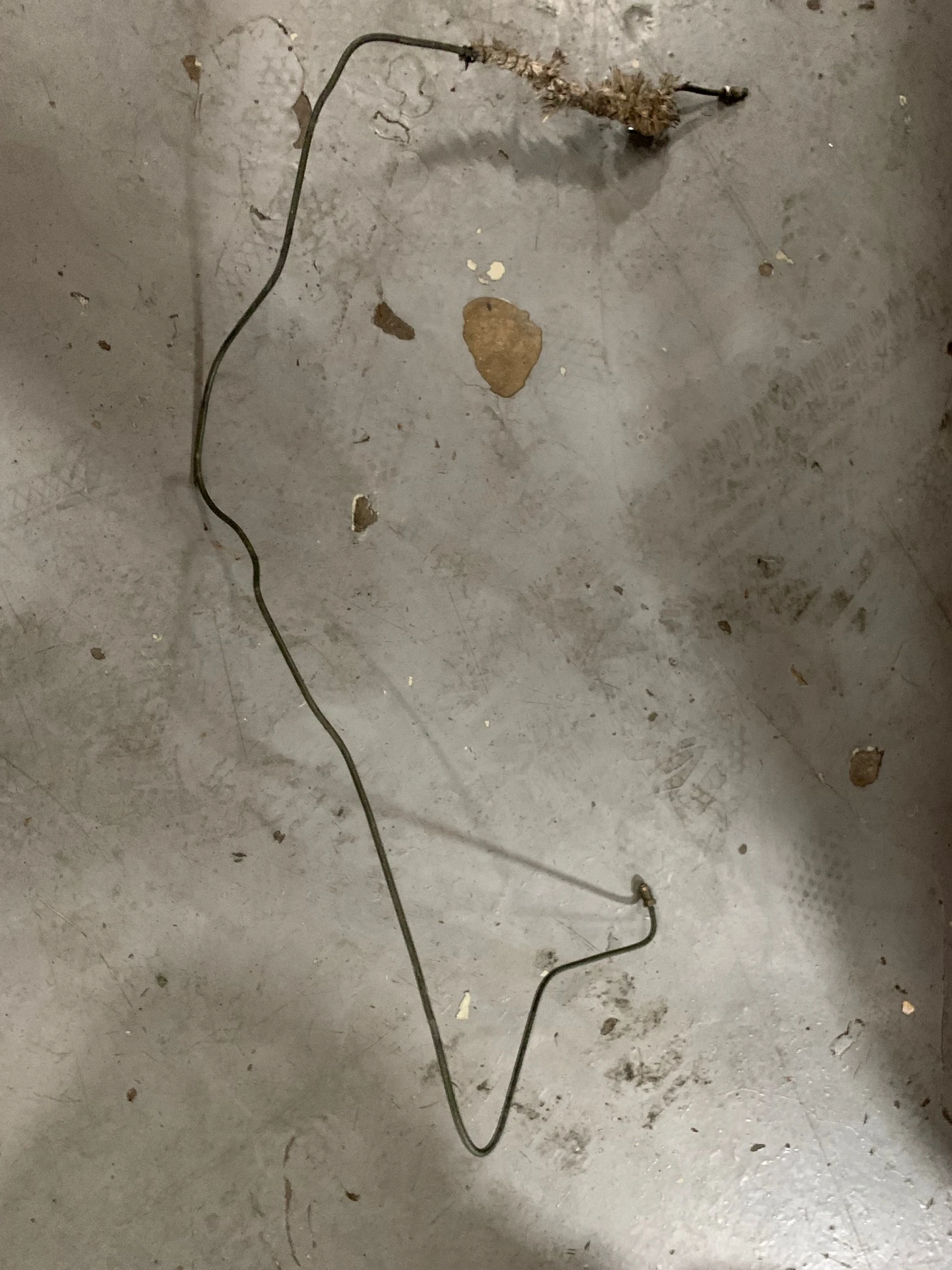

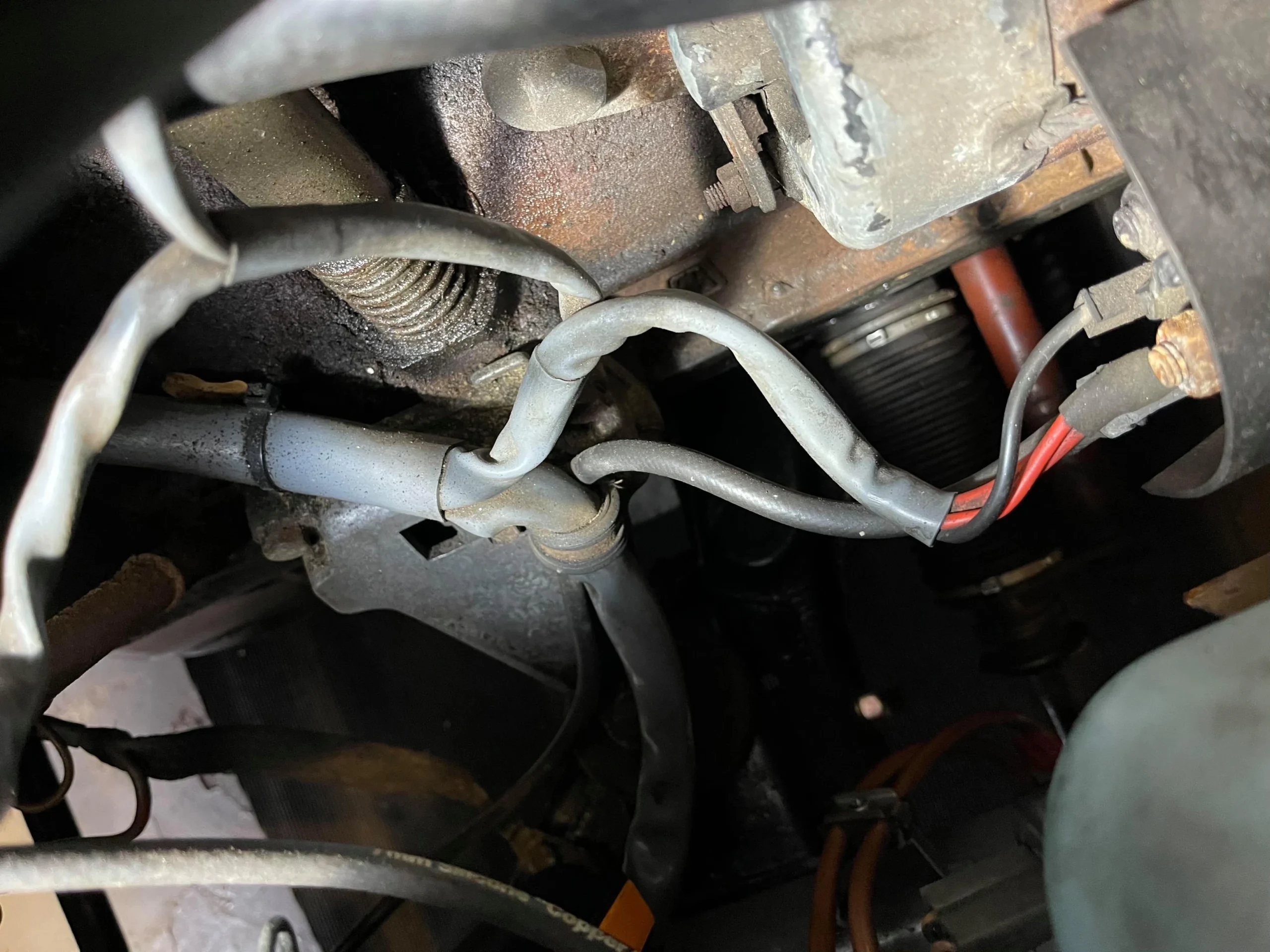

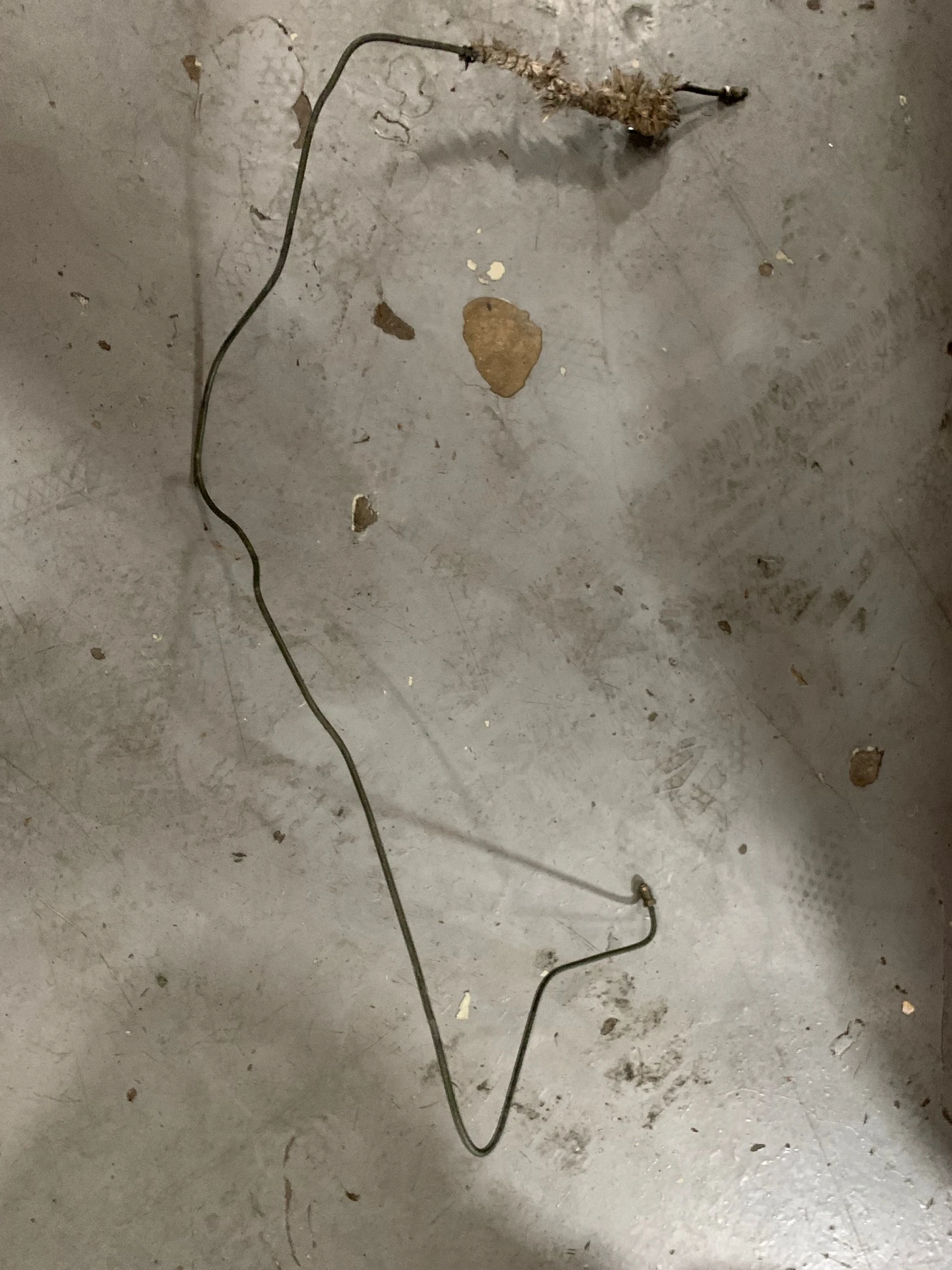

<PICs of old brake line>

When you buy brake line, BMW provides a straight piece of brake line that you have to bend to fit. What really makes it a challenge is that the line takes a very circuitous route from the master to the caliper and the original line was bent when it was taken out and it couldn’t be used as a template. I got a pic of the route, which was helpful but still not specific enough. We went to a junk yard and were gifted a template (the old rusted line from a carcass of a 320i). Using a template made mimicking the route much easier and the finished product looks as good as from the factory.

After that, the rest of the brake system—booster, new master cylinder, and reservoir—get installed. The brake master was one of those problems with the delayed project. Four years ago I ordered a new one but when I went to install it, the fittings where the brakes lines screwed in were in the wrong places. Too late to return it, I had to get another new one, this one fitting just right.

After that, the rest of the brake system—booster, new master cylinder, and reservoir—get installed. The brake master was one of those problems with the delayed project. Four years ago I ordered a new one but when I went to install it, the fittings where the brakes lines screwed in were in the wrong places. Too late to return it, I had to get another new one, this one fitting just right.

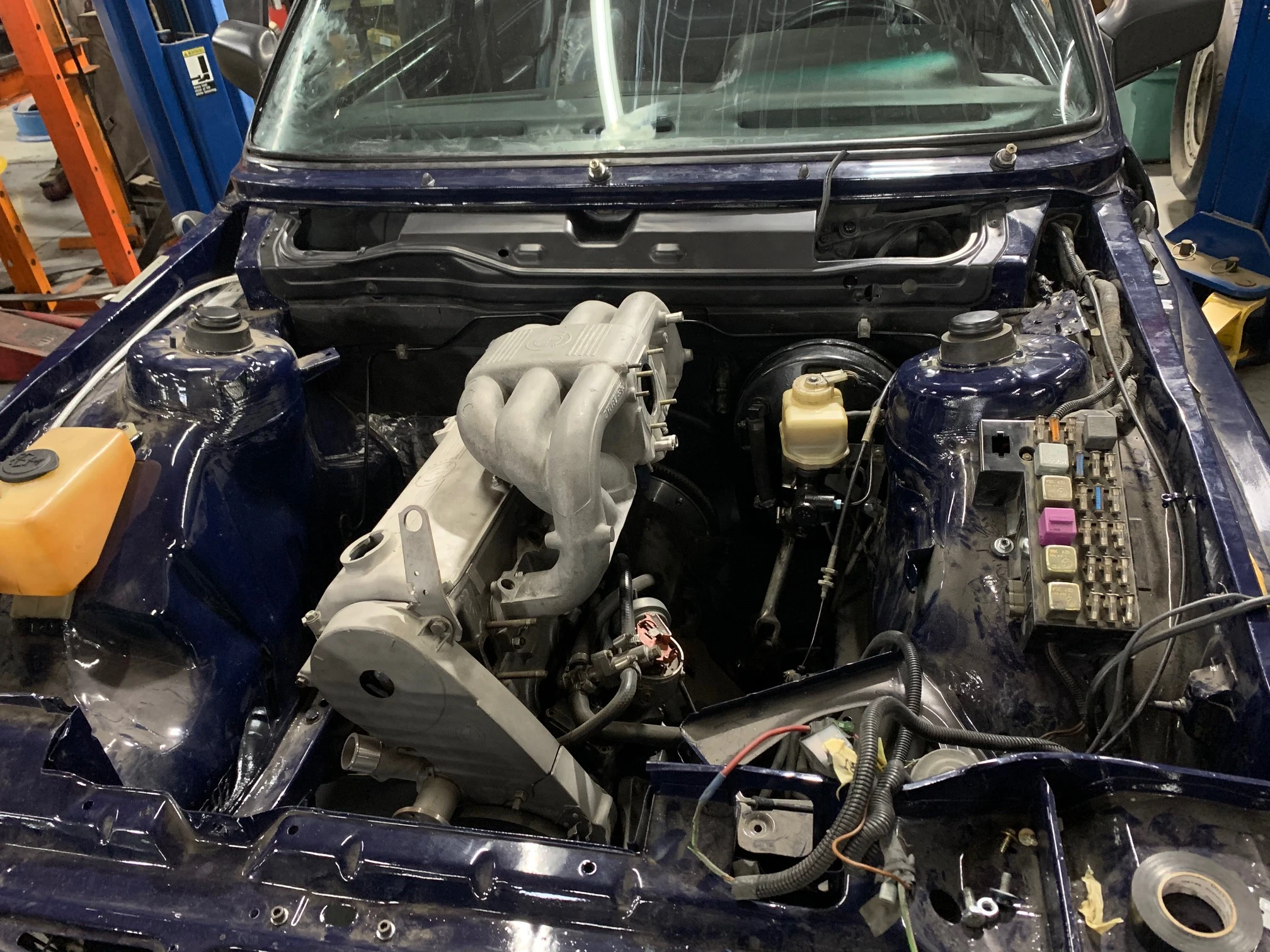

With most of the work done to the engine compartment, it was time to drop-in the motor. Putting in the motor was pretty straight-forward and two nuts later, it was part of the car again.

With most of the work done to the engine compartment, it was time to drop-in the motor. Putting in the motor was pretty straight-forward and two nuts later, it was part of the car again.

With the long block in, building it up to be a working motor was up next. The old thermostat manifold was not in great shape and need some heat to take it apart.

With the long block in, building it up to be a working motor was up next. The old thermostat manifold was not in great shape and need some heat to take it apart.

by alpinac1_pn9him | Nov 1, 2020 | Uncategorized

It’s been over two years since my last blog update and four years to the day (November 1) since I proudly posted on FaceBook that I bought this car, my first real Alpina. I say first because I now also own a 1981 B7 turbo e12 (www.alpinab7.com). I bought the B7 largely because it is just such a cool car; but, I also partly bought it because this project had stalled to a point that I wanted a cool vintage that I could drive while trying to get the e21 back in on the road.

The pandemic has helped many car enthusiasts, including me, by giving them time to wrench on their project car. Happily, most (if not all) of the attention was focused on getting the B7 in better shape. The car was not well-cared for over the years and, while it was a decent driver-condition car, it needed a bunch of TLC. And the pandemic kept me at home where I could order parts on-line and wrench on the car, giving it the much-needed attention.

The pandemic, however, did not help this project. Stu’s shop was negatively effected by the pandemic, losing mechanics (not because the virus) and forcing him to focus on his day-to-day business and not follies like restoring old Alpinas. He does, after all, have a shop to run, customers to keep happy and on the road, and bills to pay with normal, more profitable work. So, the C1 was the neglected red-haired step child. The C1 had been painted but not reassembled (Stu sold his body shop and the car was moved to the main shop, but mostly sat, waiting for Stu to have free time to put it back together).

I got to a certain point with the B7—sort of a go big or go home point, where the car should just be driven as-is or take a big step in restoration. Regardless of the path chosen, I passed the point of tinkering on it in my garage, as going “big” meant it taking it back to the turbo specialists who would make the fuel injection more reliable—a job way, way above my pay-grade. At those cross-roads with the B7, I turned my attention to the C1, which began with a call to Stu.

I figured the best way to get this project going forward was for me to go up to Sacramento and start assembling the car myself. Before I could make that suggestion Stu says “you should come up here and do the easier stuff yourself and help me do the harder stuff.” I jumped at it and we made a plan. That was a few weeks back and I’ve gone up three times (so far) in the past two weeks.

Our first job was putting the “new” dash in the car. The original dash had been sent to Just Dashes for repairs, which looked great but the fit was tight. With me, Stu, and his 18-year-old shop helper pushing and pulling, we got it in.

Stu worked on installing the new the headliner.

Stu worked on installing the new the headliner.

And I bolted up the valance panel.

And I bolted up the valance panel.

Much of my time was spent organizing the parts taken off in disassembly, which took a good amount of time. The guys at the body shop took it apart assuming they’d be putting it back together immediately so the disassembly was not organized in anticipation of a multi-year project. Finding everything more than two years later was (and continues to be) a challenge, but not an insurmountable one. While searching for unlabeled, haphazardly placed parts is not particularly fun, the project is: all my past restorations have been mechanical or interior work. Reassembling a car striped for paint is a new experience. And a good portion of the satisfaction of a project for me is the connection, the bond, one gets with a car when restoring it. And I’m feeling a special bond with his project, with its new (to me) challenges; challenges akin to building a car anew.

Much of my time was spent organizing the parts taken off in disassembly, which took a good amount of time. The guys at the body shop took it apart assuming they’d be putting it back together immediately so the disassembly was not organized in anticipation of a multi-year project. Finding everything more than two years later was (and continues to be) a challenge, but not an insurmountable one. While searching for unlabeled, haphazardly placed parts is not particularly fun, the project is: all my past restorations have been mechanical or interior work. Reassembling a car striped for paint is a new experience. And a good portion of the satisfaction of a project for me is the connection, the bond, one gets with a car when restoring it. And I’m feeling a special bond with his project, with its new (to me) challenges; challenges akin to building a car anew.

Our plan is for me to keep going up to Sacramento until we get the car to a point that it can be put on the back of a trailer, driven back down to my house where I’ll finish the work.

Our plan is for me to keep going up to Sacramento until we get the car to a point that it can be put on the back of a trailer, driven back down to my house where I’ll finish the work.

by alpinac1_pn9him | Aug 25, 2018 | Uncategorized

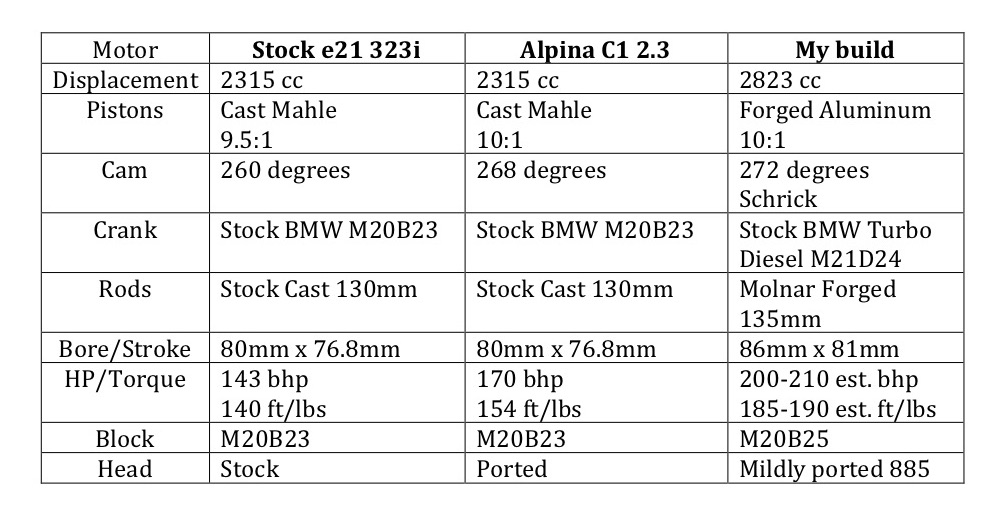

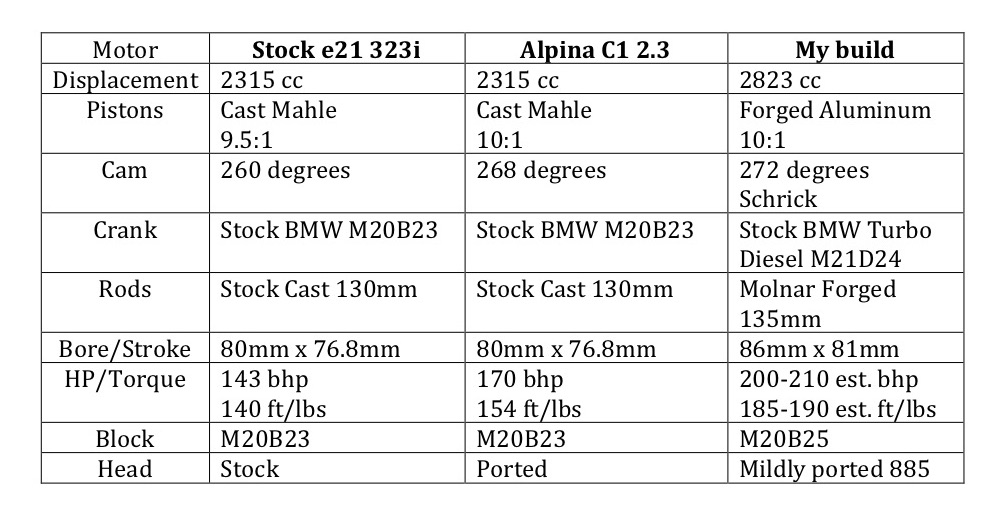

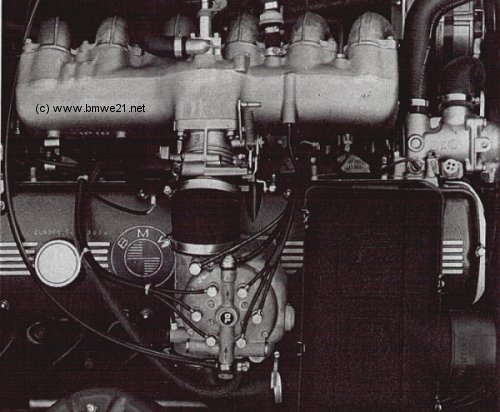

As described in the last post, the motor build is mostly completed. There are a few weird odds-and-ends yet to be done, like a drill and tap for a bolt to secure warm-up regulator to the block and such – nothing major. But I realized that the final build specifications were never discussed fully. So here’s a chart and explanation of my build, comparing it to stock BMW and the Alpina build.

Virtually every decision-point was vetted. Twenty-eight hundred cc displacement was chosen because I wanted to use a turbo-diesel crank (it’s a very stout crack, able to withstand the high pressures of the diesel motor) and I always kinda liked the e30 c2 2.7, based on the same crank and big bore. The pistons were an easy decision, given the crank and desire to get at least 2700cc. I didn’t feel the need for a much bigger bore and knew that several folks had successfully used a 86 mm bore on the stock 325i M20 block.

Virtually every decision-point was vetted. Twenty-eight hundred cc displacement was chosen because I wanted to use a turbo-diesel crank (it’s a very stout crack, able to withstand the high pressures of the diesel motor) and I always kinda liked the e30 c2 2.7, based on the same crank and big bore. The pistons were an easy decision, given the crank and desire to get at least 2700cc. I didn’t feel the need for a much bigger bore and knew that several folks had successfully used a 86 mm bore on the stock 325i M20 block.

The rods were a compromise. Because the pistons were custom, I could use virtually any BMW rod that fit the crank. If I used stock BMW rods, I would spend money buying them, testing and refreshing them, and lightening and balancing them. If I went with proven, USA forged rods like Carrillo or such I’d spend a fortune. For the same price as used rods plus machine shop work, however, I could get forged Chinese rods that were finished in the USA by a reputable shop. That is just what I did, with 135mm rods from Molnar Technologies. Tom Molnar was the Metallurgist and engineer for Oliver Rods and Cranks for over 20 years; he was the founder of K-1 Technologies and recently started his own shop. I was confident with that background that my compromise rods were built by someone with the necessary know-how.

The Schrick 272 was also a compromise camshaft, but for different reasons. Retaining the Bosch K-Jet fuel injection was the limiting factor. From what I’ve been told, the flap in the air-fuel meter is sensitive to pressure changes in the intake plenum and a higher-duration cam will create too much pressure change for the K-Jet fuel injection. Normally, with the increased displacement, I would build in more cam – and while the Schrick 272 is a “bigger” cam than the stock Alpina 268, it is not monumentally so. Obviously, it’s only 4 degrees more duration than the Alpina cam and 12 more than BMW. In the faux A4S I built, for example, I had 2.2 liters of displacement (S14 crank in stock M10 block) and a Schrick 304. The 304 has significantly more duration than the 264 degree stock M10 cam and is usually thought to be too much cam for the street, with high horsepower but little bottom-end power. But the increased displacement made up for that and the motor was actually very docile and flexible – lots of horsepower but the increased cubic inches (or centimeters, as the case may be) gave it lots of low-end torque. If I could have done that here, I would have. But no such luck and the 272 was the most duration I could comfortably get while retaining the stock(ish) K-Jet fuel injection.

The M20B25 block was chosen simply for convenience – there are a ton of them available and but for the drill-and-tap for warm-up regulator, there are no practical differences. The 885 head is said to flow best of the available M20 heads, so that choice was simple too. The head and intake plenum were mildly ported and matched.

I guestimate the motor to put out about 200 horsepower and 185 foot-pounds of torque. Both numbers represent a gain of 30 horsepower and foot-pounds. The horsepower is an educated guess, starting at the Alpina 170 mark for the 2.3 liter C1 motor and then comparing to the Alpina B6 2.8, which has a tad less displacement (2788 v. 2823). The B6 motor puts out 200 or 218, depending on fuel injection and cam. The Pierburg version of the B6, with an airflow meter similar to the K-Jet and a 260 degree cam, puts out 200. The Bosch L-Jet version with a 280 degree cam, puts out 218. Mine is probably somewhere in between but 200 should be a safe number, given the displacement, cam, compression ratio and fuel injection. (Note that Alpina used considerably less cam duration for fuel injection similar to mine.)

For torque I used the B6 2.8 as a reference point as well. The early B6 motor put out 182 and the later 195. Mine should be in the middle as well but 185 is a safe number.

For torque I used the B6 2.8 as a reference point as well. The early B6 motor put out 182 and the later 195. Mine should be in the middle as well but 185 is a safe number.

If these numbers are right, I will be getting B6 performance essentially with weight savings of 57 pounds – all at the nose. (The M20 weight is 258 lbs while the M30 is 315 pounds.) That’s not bad!

A comparison of the C1 and B6 specs can be found here: http://www.bmwe21.net/?page_id=301

Getting the sunroof back in was not easy. The entire mechanics were disassembled and most of the little parts did not stay with the shell when the body shop closed. Sourcing those small but necessary parts takes time and ingenuity. Some parts were available from BMW, some were on eBay new or used, some we got from a junk yard with an old 6-series (thankfully BMW used the same parts in several different platforms). That took many trips up to Sacramento to install the parts I got and figure out the ones I needed to get. Slow and frustrating progress.

Getting the sunroof back in was not easy. The entire mechanics were disassembled and most of the little parts did not stay with the shell when the body shop closed. Sourcing those small but necessary parts takes time and ingenuity. Some parts were available from BMW, some were on eBay new or used, some we got from a junk yard with an old 6-series (thankfully BMW used the same parts in several different platforms). That took many trips up to Sacramento to install the parts I got and figure out the ones I needed to get. Slow and frustrating progress.

Above I told you the sunroof was in. And that is true. But it was a misleading but factual statement (my lawyer training coming through!). We finally got all the parts and were able to put the sunroof in the car. But we couldn’t get it operating. Or at least fully operating. The tilt works but not the back and forth. I’m sure with time and energy it will work but I was up for two days and had other things to accomplish before leaving. Plus, I really don’t like sunroofs anyway, so having it in but not working is not anything even near a hardship for me. Finally, the sunroof and the hood were the two final steps in getting the car water tight so it could be trucked back home.

Above I told you the sunroof was in. And that is true. But it was a misleading but factual statement (my lawyer training coming through!). We finally got all the parts and were able to put the sunroof in the car. But we couldn’t get it operating. Or at least fully operating. The tilt works but not the back and forth. I’m sure with time and energy it will work but I was up for two days and had other things to accomplish before leaving. Plus, I really don’t like sunroofs anyway, so having it in but not working is not anything even near a hardship for me. Finally, the sunroof and the hood were the two final steps in getting the car water tight so it could be trucked back home.

Rear windows put in and parts for door trim being sourced from around the world.

Rear windows put in and parts for door trim being sourced from around the world.

And, most recently, the sunroof is finally being addressed. First was cleaning up the sunroof frame and installing the headliner on it. Next up will be reinstalling the sunroof mechanics, the headliner frame and then the roof itself. That may happened next week.

And, most recently, the sunroof is finally being addressed. First was cleaning up the sunroof frame and installing the headliner on it. Next up will be reinstalling the sunroof mechanics, the headliner frame and then the roof itself. That may happened next week.

But there’s plenty to still be done. The interior still needs work: There are no seats, the dash has not been populated and lots of little parts are surely missing or broken, including the heater control unit. But that can wait until after we confirm that the car will actually run. To get there, I have a ton of details that need attention: wire in the coil (replaced by an MSD by a previous owner); finish other electric details, like sourcing and attaching battery leads; and plumb in the rest of the fuel delivery system.

But there’s plenty to still be done. The interior still needs work: There are no seats, the dash has not been populated and lots of little parts are surely missing or broken, including the heater control unit. But that can wait until after we confirm that the car will actually run. To get there, I have a ton of details that need attention: wire in the coil (replaced by an MSD by a previous owner); finish other electric details, like sourcing and attaching battery leads; and plumb in the rest of the fuel delivery system.

Four weeks later DHL delivered the gaskets and I finally had everything needed to put in the door locks. Getting the lock cylinder into the door was a trick, at least for someone like me who has never done it before. I started with the passenger side. The cylinder seemingly did not fit into the hole in the door; after fruitlessly trying to wiggling it in, I got more and more forceful, pushing it and then finally I held it centered on the hole and hit it with the palm of my hand. It barely went in and fell out as soon as I touched it. But, progress (however slight). A small hammer and gentle taps and it was in, but not by much—maybe a quarter-inch. Hit it a little harder and it went further in. Even harder and it was halfway in. Consistent gentle taps slowly morphed into firmer hits and it was getting closer and closer; it took a mere half an hour to get it firmly planted in the door. Learning how hard I could hit it took time; the fit was so tight it needed some serious force but I didn’t want to wack it too hard and damage the door. Then it took me 15 minutes to figure out how to attach little arm on the back of the cylinder to the lock; adding to the frustration was working in a tight space with no good line-of-sight. But, I figured out what parts of the door innards to disassemble to get room and sight; once I did, it was an easy job. The passenger side took 45 minutes (most of that being the learning curve), but the second one was finished in less than ten minutes. Knowledge is a powerful tool!

Four weeks later DHL delivered the gaskets and I finally had everything needed to put in the door locks. Getting the lock cylinder into the door was a trick, at least for someone like me who has never done it before. I started with the passenger side. The cylinder seemingly did not fit into the hole in the door; after fruitlessly trying to wiggling it in, I got more and more forceful, pushing it and then finally I held it centered on the hole and hit it with the palm of my hand. It barely went in and fell out as soon as I touched it. But, progress (however slight). A small hammer and gentle taps and it was in, but not by much—maybe a quarter-inch. Hit it a little harder and it went further in. Even harder and it was halfway in. Consistent gentle taps slowly morphed into firmer hits and it was getting closer and closer; it took a mere half an hour to get it firmly planted in the door. Learning how hard I could hit it took time; the fit was so tight it needed some serious force but I didn’t want to wack it too hard and damage the door. Then it took me 15 minutes to figure out how to attach little arm on the back of the cylinder to the lock; adding to the frustration was working in a tight space with no good line-of-sight. But, I figured out what parts of the door innards to disassemble to get room and sight; once I did, it was an easy job. The passenger side took 45 minutes (most of that being the learning curve), but the second one was finished in less than ten minutes. Knowledge is a powerful tool! Another challenge was figuring out how the bundle of wires was supposed to routed through the engine compartment. I looked at the harness, which had an ugly re-wrap in electrical tape, and it was not at all apparent how to get from the fusebox to the headlights and horns. I inquired on the FaceBook e21 group and I found someone who restored a similar C1 2.3 (really, any e21 would have been fine, but it was great to find someone who did such a great job and documented it with photos). He sent pictures of his wiring and I was in business. I re-wrapped the harness in friction tape and routed it through the engine compartment.

Another challenge was figuring out how the bundle of wires was supposed to routed through the engine compartment. I looked at the harness, which had an ugly re-wrap in electrical tape, and it was not at all apparent how to get from the fusebox to the headlights and horns. I inquired on the FaceBook e21 group and I found someone who restored a similar C1 2.3 (really, any e21 would have been fine, but it was great to find someone who did such a great job and documented it with photos). He sent pictures of his wiring and I was in business. I re-wrapped the harness in friction tape and routed it through the engine compartment.

With the wiring in, next was the bumpers. They had been sitting around the shop literally collecting dust. I washed them off and then installed them.

With the wiring in, next was the bumpers. They had been sitting around the shop literally collecting dust. I washed them off and then installed them.

Then I installed the horns and lights and then grills.

Then I installed the horns and lights and then grills. Putting the air dam on the car was one of the interesting archaeological parts of the restoration. The air dam has brake cooling ducts but behind the ducts on a stock body is the lower valance. So the boys at Buchloe cut a rectangle out of the valance to allow the air to flow to the brakes. Those cuts were uneven and kind of primitive. Honestly, they looked like something I would do in my garage!

Putting the air dam on the car was one of the interesting archaeological parts of the restoration. The air dam has brake cooling ducts but behind the ducts on a stock body is the lower valance. So the boys at Buchloe cut a rectangle out of the valance to allow the air to flow to the brakes. Those cuts were uneven and kind of primitive. Honestly, they looked like something I would do in my garage! And sometimes it’s just fun cleaning things up and making them look spiffy; the hood latches were old and rusty, so into the media blaster they went. Quickly they were cleaned up and sprayed with lacquer. A serious improvement.

And sometimes it’s just fun cleaning things up and making them look spiffy; the hood latches were old and rusty, so into the media blaster they went. Quickly they were cleaned up and sprayed with lacquer. A serious improvement.

A project like this has a ton of small things that need to be done, like running the wire back through the small channels on the inside of the trunk lid. Fitting the wiring through those channel can be a challenge, but patience and persistence pay off.

A project like this has a ton of small things that need to be done, like running the wire back through the small channels on the inside of the trunk lid. Fitting the wiring through those channel can be a challenge, but patience and persistence pay off.

But it also has some significant challenges. One was the metal brake line to the caliper on the front passenger side. The original one was bent, weak, and just ugly.

But it also has some significant challenges. One was the metal brake line to the caliper on the front passenger side. The original one was bent, weak, and just ugly. After that, the rest of the brake system—booster, new master cylinder, and reservoir—get installed. The brake master was one of those problems with the delayed project. Four years ago I ordered a new one but when I went to install it, the fittings where the brakes lines screwed in were in the wrong places. Too late to return it, I had to get another new one, this one fitting just right.

After that, the rest of the brake system—booster, new master cylinder, and reservoir—get installed. The brake master was one of those problems with the delayed project. Four years ago I ordered a new one but when I went to install it, the fittings where the brakes lines screwed in were in the wrong places. Too late to return it, I had to get another new one, this one fitting just right. With most of the work done to the engine compartment, it was time to drop-in the motor. Putting in the motor was pretty straight-forward and two nuts later, it was part of the car again.

With most of the work done to the engine compartment, it was time to drop-in the motor. Putting in the motor was pretty straight-forward and two nuts later, it was part of the car again. With the long block in, building it up to be a working motor was up next. The old thermostat manifold was not in great shape and need some heat to take it apart.

With the long block in, building it up to be a working motor was up next. The old thermostat manifold was not in great shape and need some heat to take it apart.

The fuel injection is up next but offers some challenges. With the bigger displacement, the stock 323i/C1 fuel injection won’t flow enough fuel. Four years ago, I bought the necessary parts (I’ll describe those in a future post) but Stu swears he doesn’t have them and I can’t find them in my parts stash. Luckily, Stu had similar ones in his parts stash and we should, soon, be good to go on that front…..

The fuel injection is up next but offers some challenges. With the bigger displacement, the stock 323i/C1 fuel injection won’t flow enough fuel. Four years ago, I bought the necessary parts (I’ll describe those in a future post) but Stu swears he doesn’t have them and I can’t find them in my parts stash. Luckily, Stu had similar ones in his parts stash and we should, soon, be good to go on that front….. Stu worked on installing the new the headliner.

Stu worked on installing the new the headliner.

The three of us put in the windshield.

The three of us put in the windshield. And I bolted up the valance panel.

And I bolted up the valance panel. Much of my time was spent organizing the parts taken off in disassembly, which took a good amount of time. The guys at the body shop took it apart assuming they’d be putting it back together immediately so the disassembly was not organized in anticipation of a multi-year project. Finding everything more than two years later was (and continues to be) a challenge, but not an insurmountable one. While searching for unlabeled, haphazardly placed parts is not particularly fun, the project is: all my past restorations have been mechanical or interior work. Reassembling a car striped for paint is a new experience. And a good portion of the satisfaction of a project for me is the connection, the bond, one gets with a car when restoring it. And I’m feeling a special bond with his project, with its new (to me) challenges; challenges akin to building a car anew.

Much of my time was spent organizing the parts taken off in disassembly, which took a good amount of time. The guys at the body shop took it apart assuming they’d be putting it back together immediately so the disassembly was not organized in anticipation of a multi-year project. Finding everything more than two years later was (and continues to be) a challenge, but not an insurmountable one. While searching for unlabeled, haphazardly placed parts is not particularly fun, the project is: all my past restorations have been mechanical or interior work. Reassembling a car striped for paint is a new experience. And a good portion of the satisfaction of a project for me is the connection, the bond, one gets with a car when restoring it. And I’m feeling a special bond with his project, with its new (to me) challenges; challenges akin to building a car anew. Our plan is for me to keep going up to Sacramento until we get the car to a point that it can be put on the back of a trailer, driven back down to my house where I’ll finish the work.

Our plan is for me to keep going up to Sacramento until we get the car to a point that it can be put on the back of a trailer, driven back down to my house where I’ll finish the work. Virtually every decision-point was vetted. Twenty-eight hundred cc displacement was chosen because I wanted to use a turbo-diesel crank (it’s a very stout crack, able to withstand the high pressures of the diesel motor) and I always kinda liked the e30 c2 2.7, based on the same crank and big bore. The pistons were an easy decision, given the crank and desire to get at least 2700cc. I didn’t feel the need for a much bigger bore and knew that several folks had successfully used a 86 mm bore on the stock 325i M20 block.

Virtually every decision-point was vetted. Twenty-eight hundred cc displacement was chosen because I wanted to use a turbo-diesel crank (it’s a very stout crack, able to withstand the high pressures of the diesel motor) and I always kinda liked the e30 c2 2.7, based on the same crank and big bore. The pistons were an easy decision, given the crank and desire to get at least 2700cc. I didn’t feel the need for a much bigger bore and knew that several folks had successfully used a 86 mm bore on the stock 325i M20 block.

For torque I used the B6 2.8 as a reference point as well. The early B6 motor put out 182 and the later 195. Mine should be in the middle as well but 185 is a safe number.

For torque I used the B6 2.8 as a reference point as well. The early B6 motor put out 182 and the later 195. Mine should be in the middle as well but 185 is a safe number.