The Motor, completed. Sort of.

The last post – Death by a thousand delays – ended with more parts missing and some health issues for me, causing another delay. But, it turned out the time off from work allowed me to focus on the motor. And I got it out the door and off to Sacramento, to be tinkered with a tad and then, hopefully soon, dropped in the car.

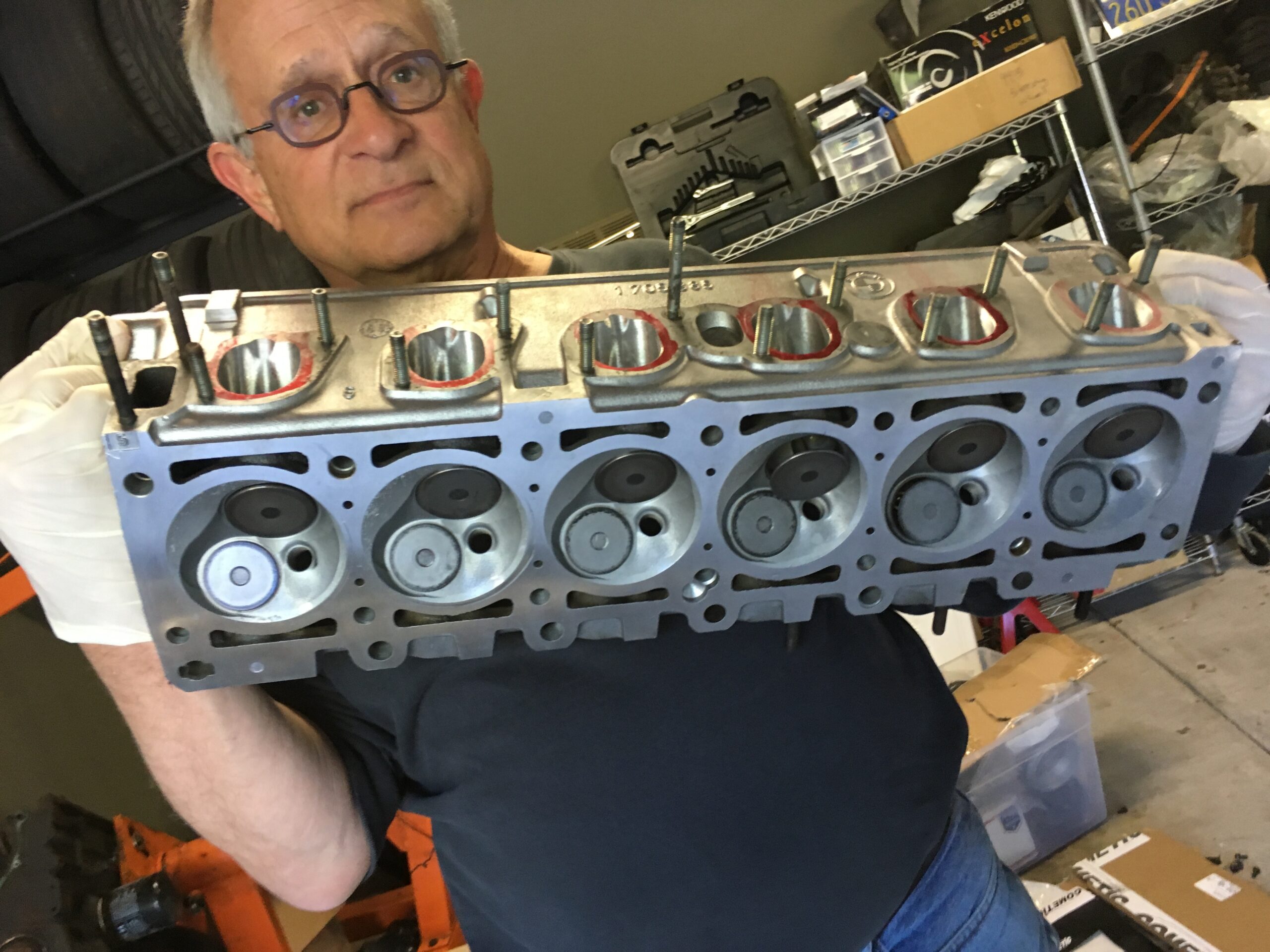

With the washers for the head bolts sourced, I was able to finally install the head.

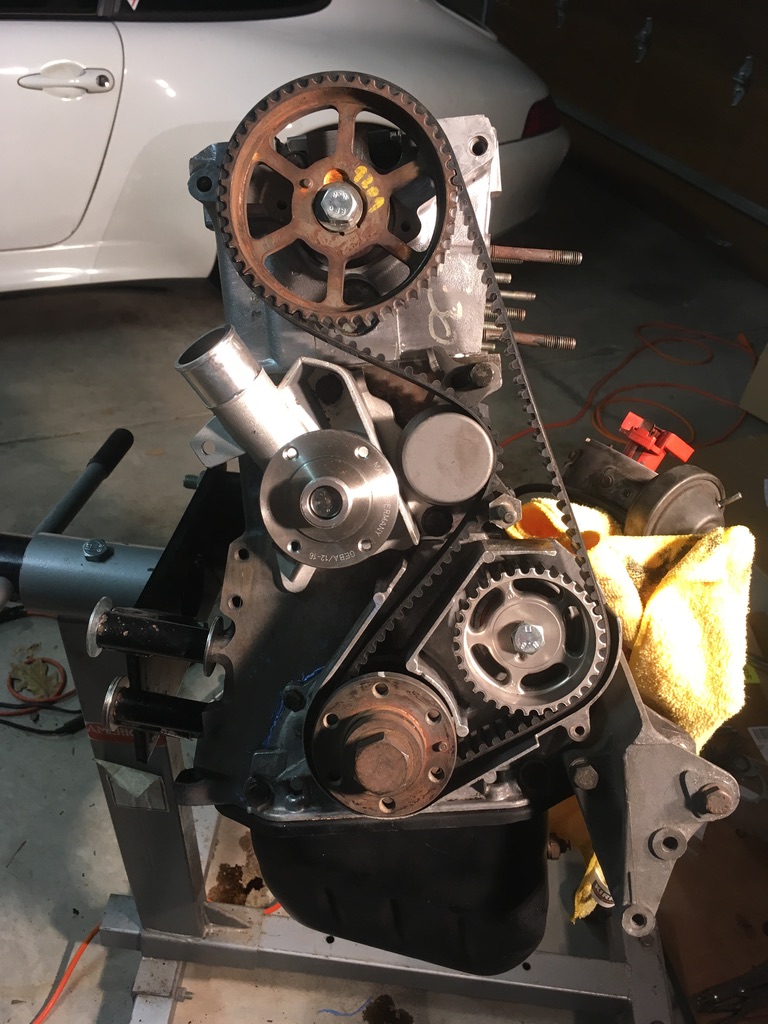

And then the drive belt and the pulleys.

And then the drive belt and the pulleys.

Then the oil pan was ready to go on.

Then the oil pan was ready to go on.

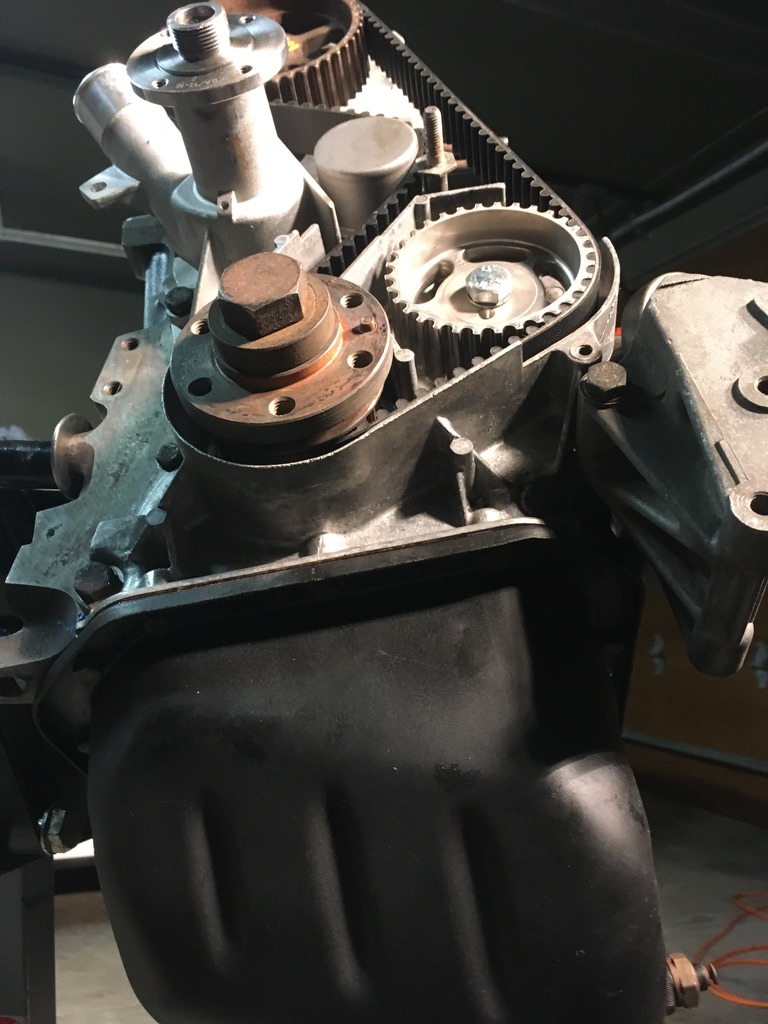

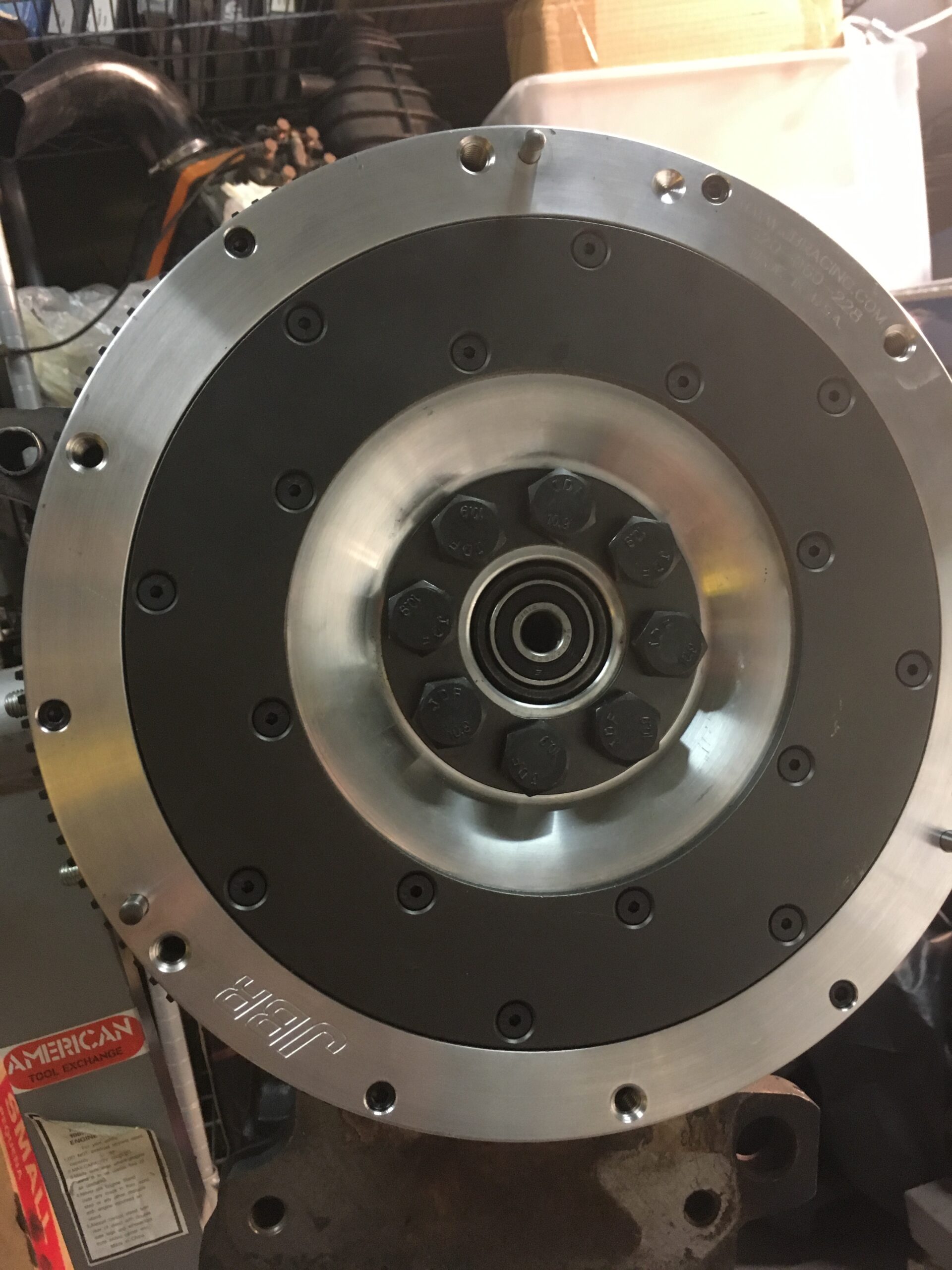

And then the rest of the rotating mass and the front covers.

And then the rest of the rotating mass and the front covers.

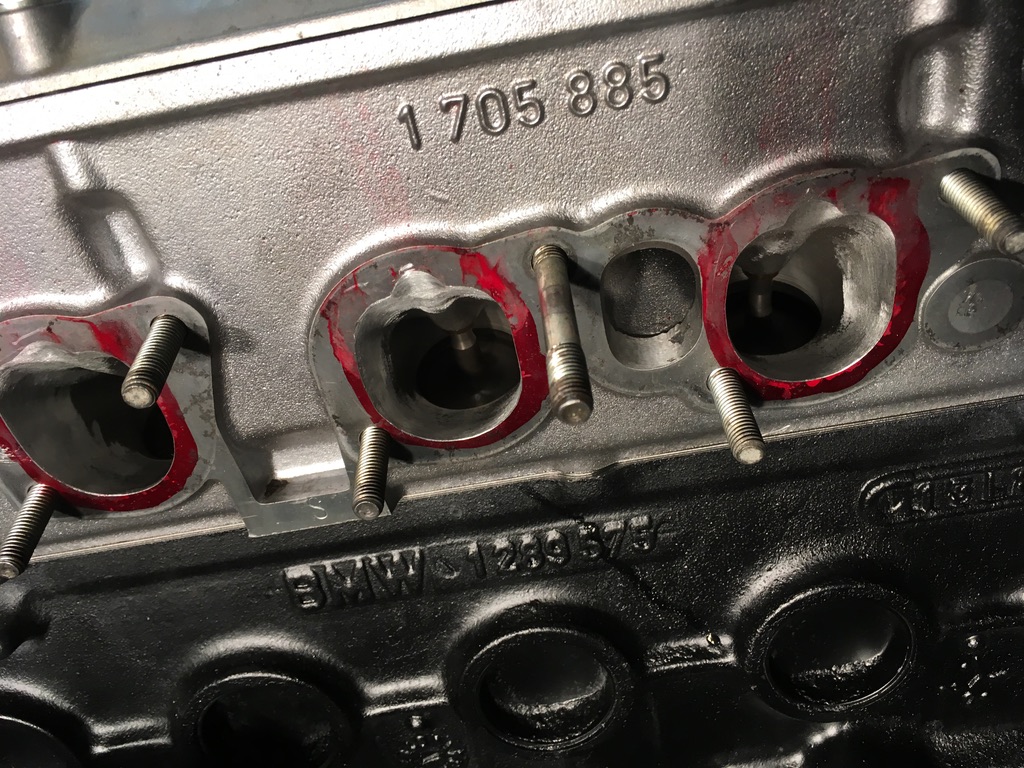

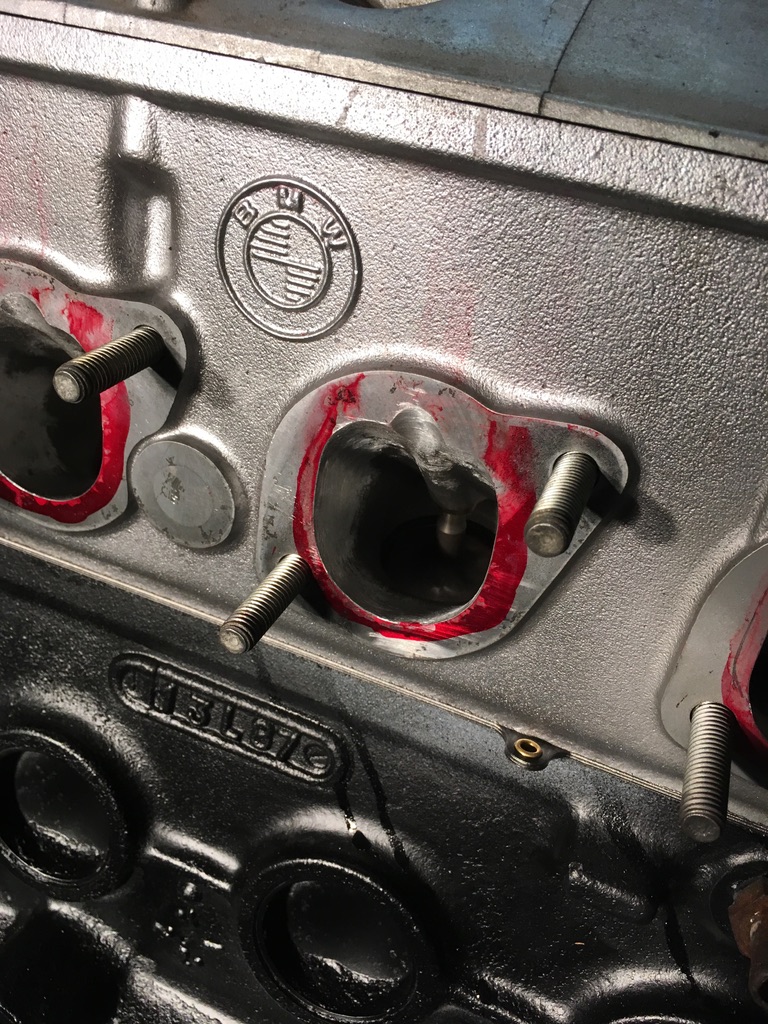

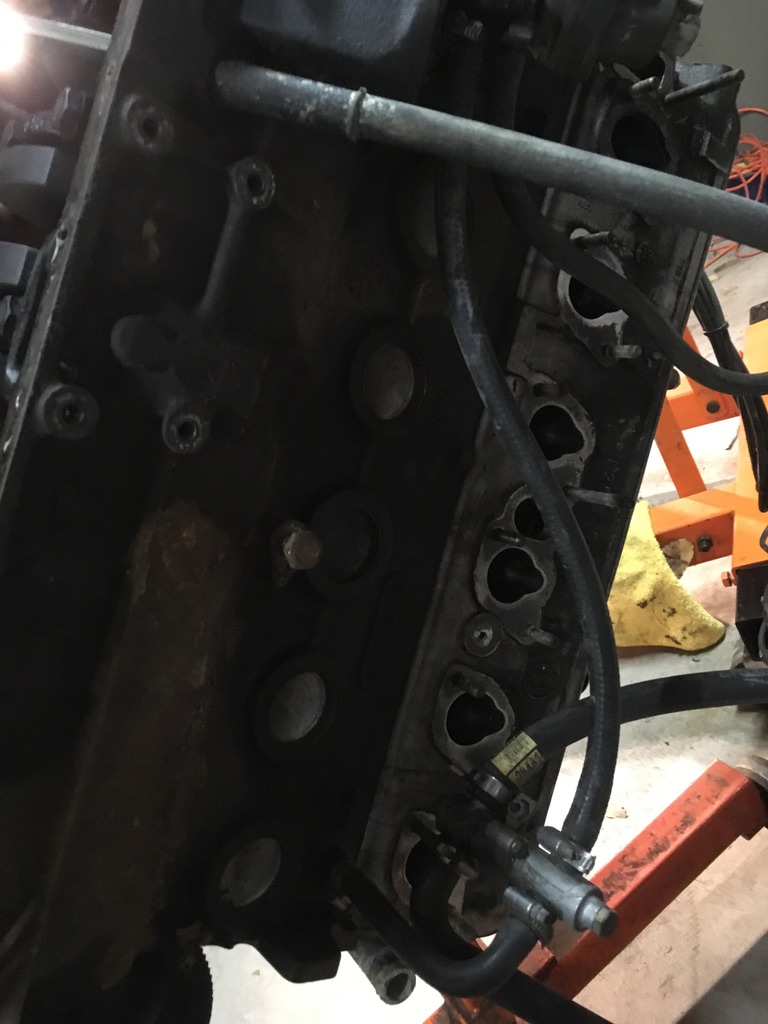

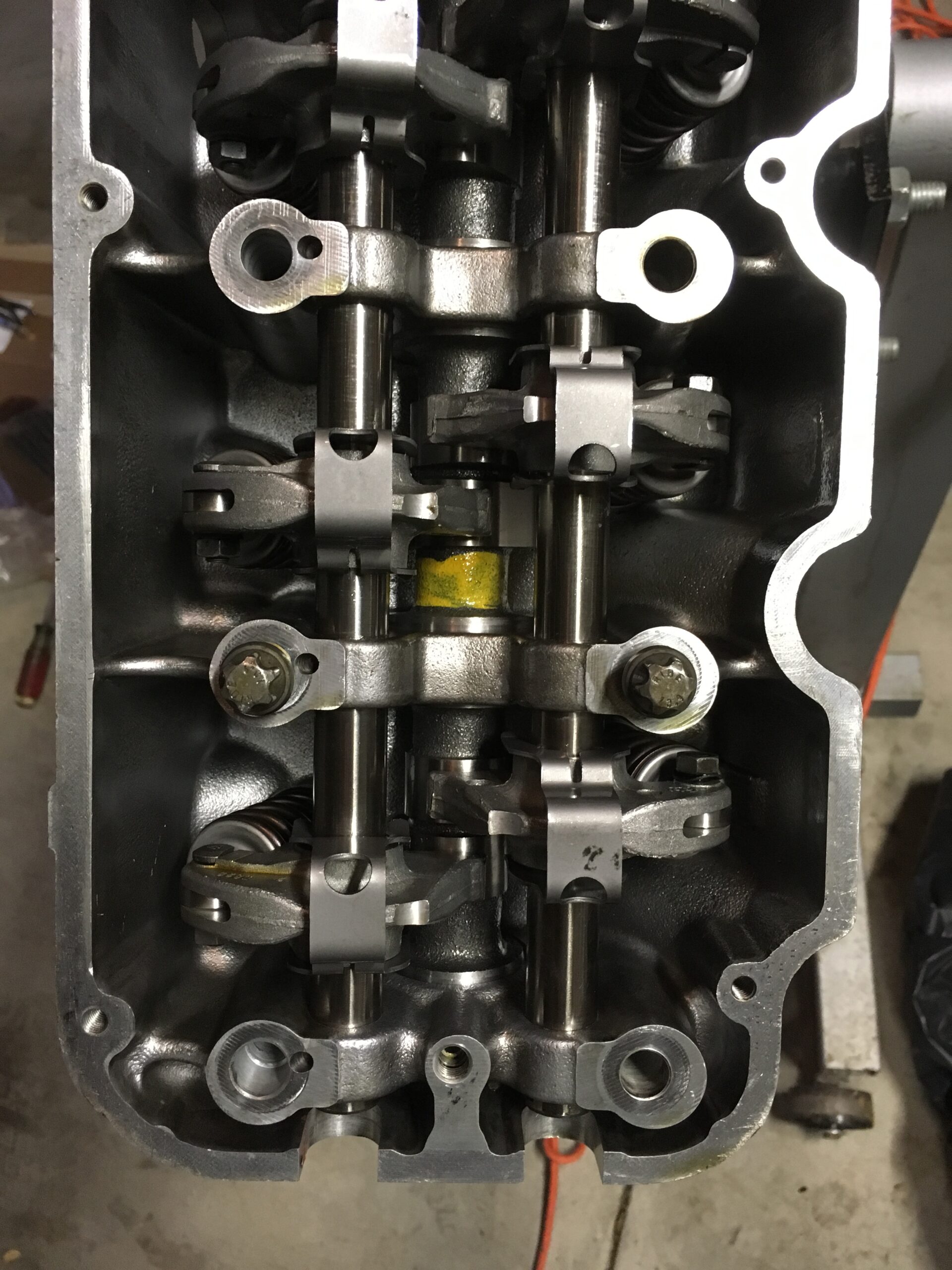

Once the motor was assembled, I was able to take some time to appreciate the machine work. Here, the intake ports were gasket matched to the intake manifold.

Once the motor was assembled, I was able to take some time to appreciate the machine work. Here, the intake ports were gasket matched to the intake manifold.

And visa-versa for the intake manifold.

And visa-versa for the intake manifold.

I made plans with Stu for him to bring his X5 down to my house and pick up the motor and the various parts. That meant next up for me was organizing the other parts. Got a couple or four bins of parts together.

I made plans with Stu for him to bring his X5 down to my house and pick up the motor and the various parts. That meant next up for me was organizing the other parts. Got a couple or four bins of parts together.

And put the motor on the cherry picker.

And put the motor on the cherry picker.

Stu came and picked up the motor late one night, and after getting it to his shop, he had a chance to look it over. After looking at the intake manifold, he asked if it was ok for him to smooth the porting out a little. Of course! He also wants to pretty up the front covers and the harmonic balancer on the front crank pulley. Why not! I’m sure these will delay the project some more, but I clearly am not making my original goal of a late August debut at Monterey, so I have another year to get everything done.

Stu came and picked up the motor late one night, and after getting it to his shop, he had a chance to look it over. After looking at the intake manifold, he asked if it was ok for him to smooth the porting out a little. Of course! He also wants to pretty up the front covers and the harmonic balancer on the front crank pulley. Why not! I’m sure these will delay the project some more, but I clearly am not making my original goal of a late August debut at Monterey, so I have another year to get everything done.

For now the garage is empty, but for the greasy old Alpina motor.

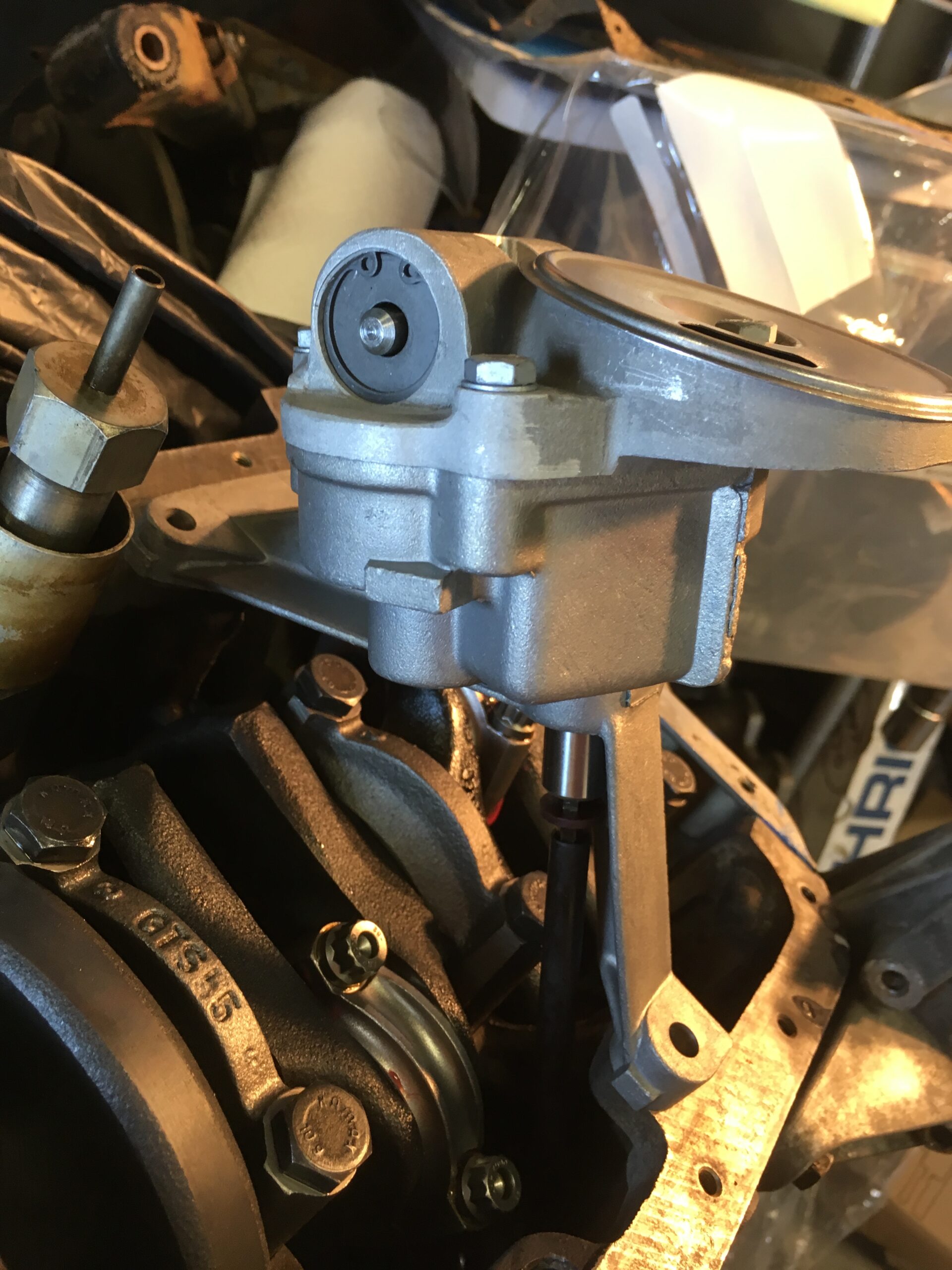

When wrenching on that, something interesting was discovered. The warm-up regulator bolts to the block (on top of a manifold that has coolant running through it). When unbolting those for Stu to take to Sacramento, we found the bottom of the manifold is exposed to the sump, with a bore through the block and a nice rubber gasket to keep it sealed. Why? What does that accomplish? The m10 K-Jet doesn’t do that and we can’t figure out why the M20 does – so, is it necessary to bore out the new block? We don’t think so, but if you know otherwise, feel free to let me know.

When wrenching on that, something interesting was discovered. The warm-up regulator bolts to the block (on top of a manifold that has coolant running through it). When unbolting those for Stu to take to Sacramento, we found the bottom of the manifold is exposed to the sump, with a bore through the block and a nice rubber gasket to keep it sealed. Why? What does that accomplish? The m10 K-Jet doesn’t do that and we can’t figure out why the M20 does – so, is it necessary to bore out the new block? We don’t think so, but if you know otherwise, feel free to let me know.

Next up is pulling the Alpina motor apart and figuring out what is in there and whether the head gasket is blown. Then I’ll clean it up and freshen up the innards.

Next up is pulling the Alpina motor apart and figuring out what is in there and whether the head gasket is blown. Then I’ll clean it up and freshen up the innards.

In the meantime, there’s an empty garage space and nature does abhor a vacuum. Will something come up and take that space? An ’02 project? That amazing looking e12 with the S38 on Bring-a-Trailer? An e30 M3? Or will sanity win-out?

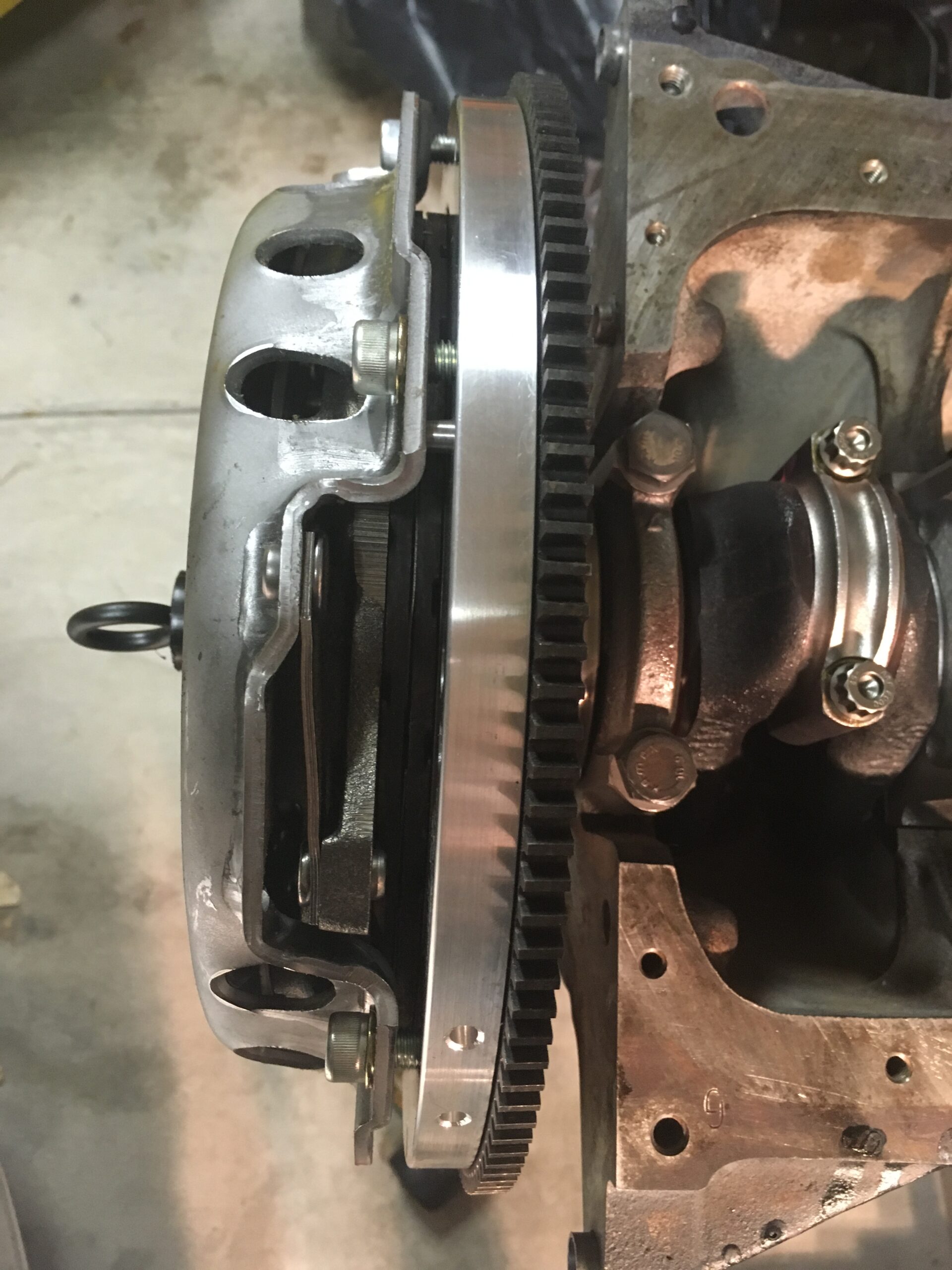

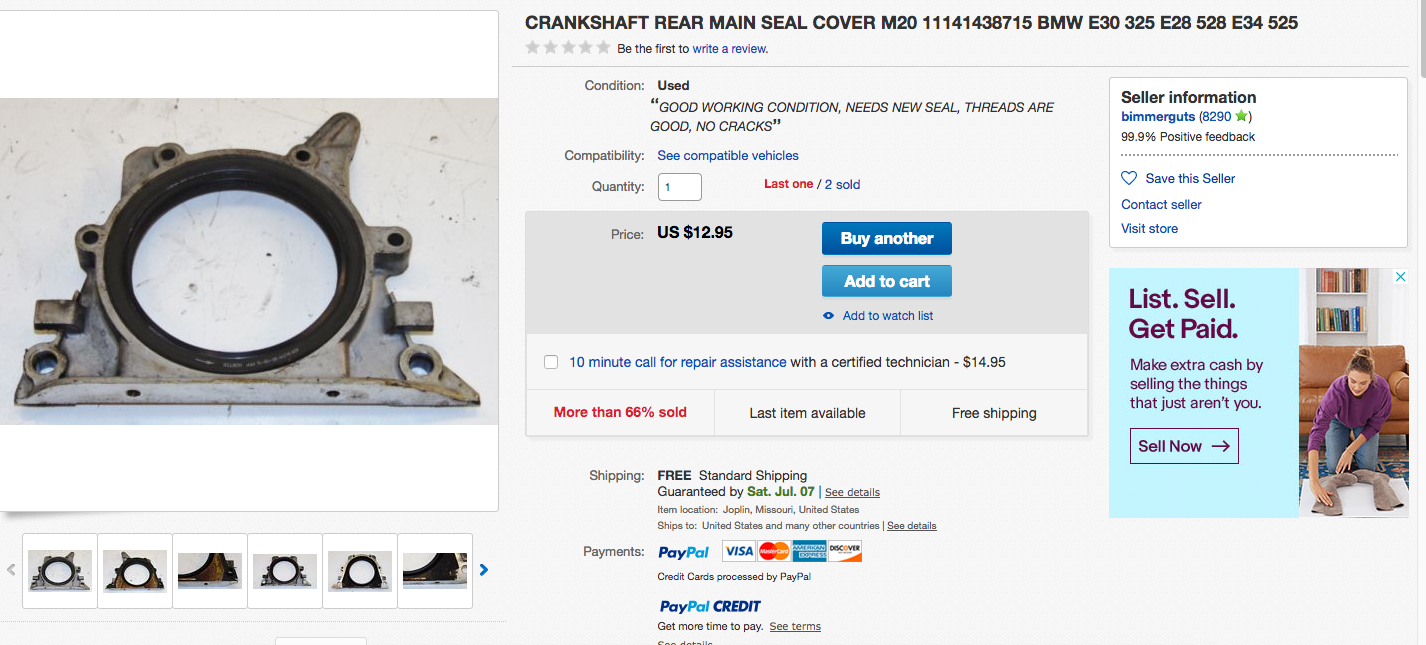

Shortly after doing that, I realized I made a bone-headed mistake and didn’t install the rear main seal nor its housing. A legitimate question: How could this happen? The best excuse I have is that I haven’t disassembled the original engine, bought a used block and that part wasn’t included – and then, in all the excitement of getting the rotating assembly together, I simply forgot about such things.

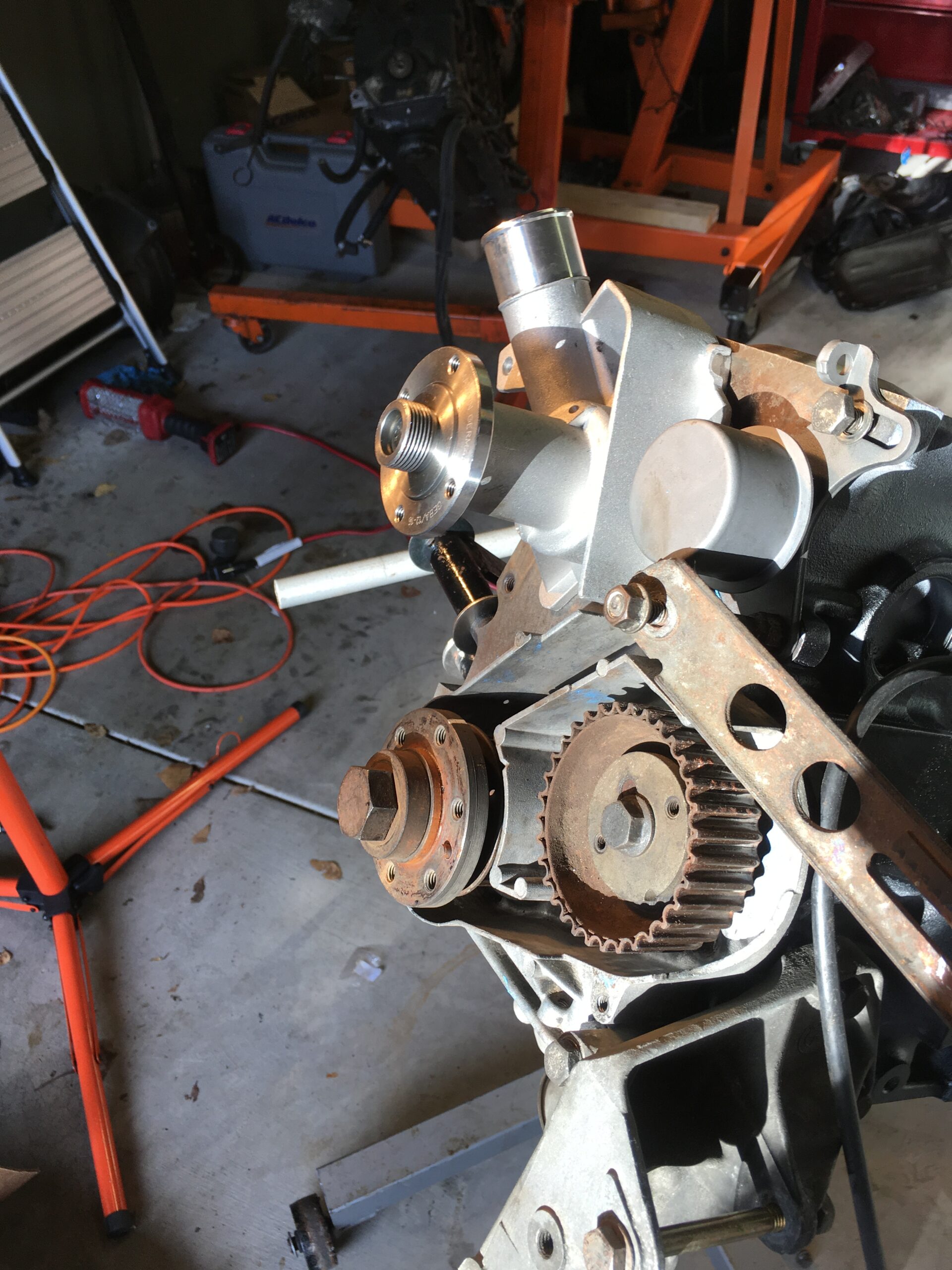

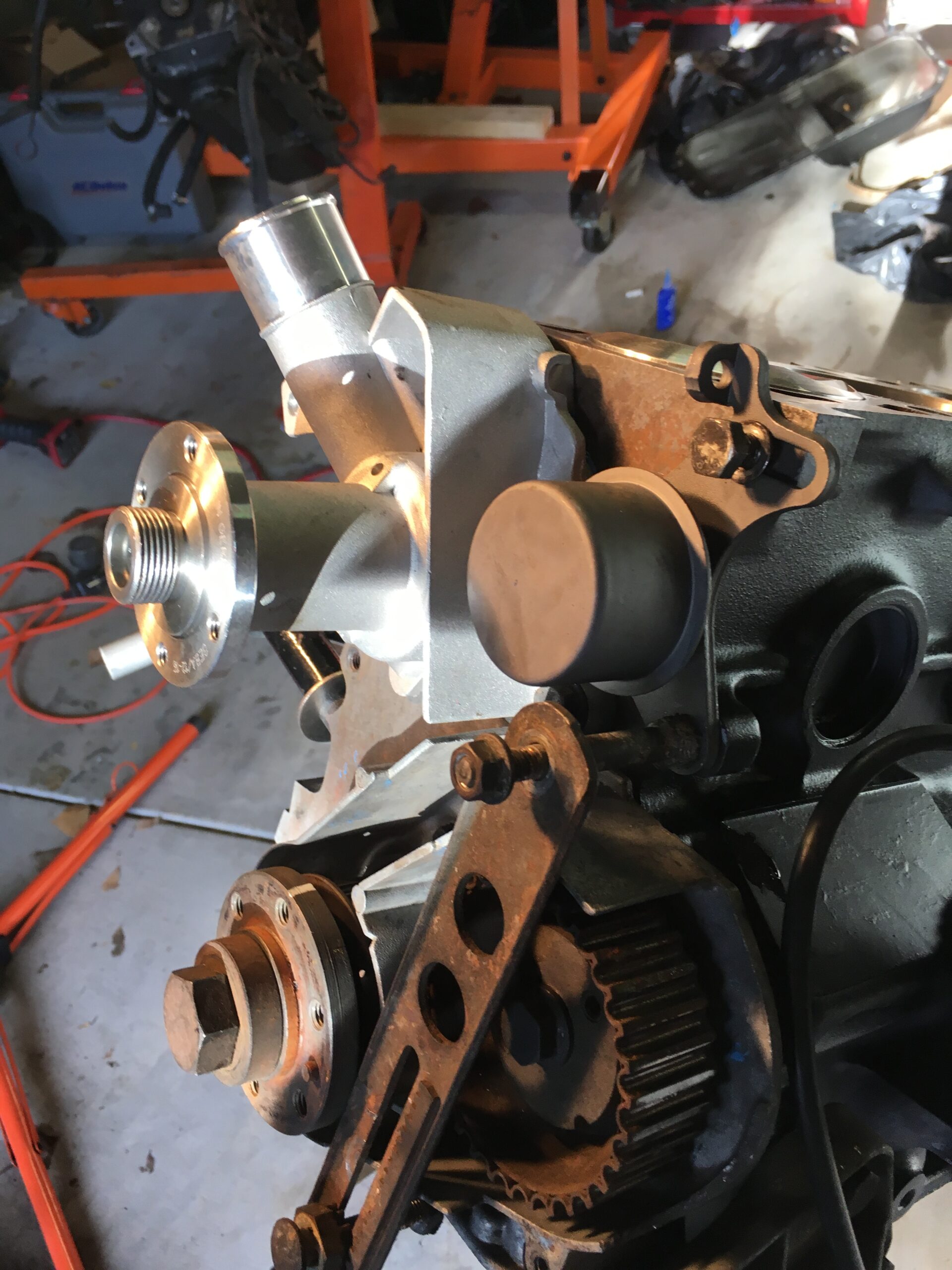

Shortly after doing that, I realized I made a bone-headed mistake and didn’t install the rear main seal nor its housing. A legitimate question: How could this happen? The best excuse I have is that I haven’t disassembled the original engine, bought a used block and that part wasn’t included – and then, in all the excitement of getting the rotating assembly together, I simply forgot about such things. Having never work on an M20 motor before – let alone built one – the next steps vexed me. Unsure of how to tackle it, I started taking the front covers and hubs around the timing belt.

Having never work on an M20 motor before – let alone built one – the next steps vexed me. Unsure of how to tackle it, I started taking the front covers and hubs around the timing belt. This went smoothly until I encountered the screws securing the intermediate shaft drive. For some reason, instead of using allen screws, BMW used standard head machine screws. Given the torque on these, one simply refused to loosen. Worse, I started to strip the head as I tried. I went into the house, had a beer, and thought about how to get that thing loosened. It came to me: An impact screwdriver!

This went smoothly until I encountered the screws securing the intermediate shaft drive. For some reason, instead of using allen screws, BMW used standard head machine screws. Given the torque on these, one simply refused to loosen. Worse, I started to strip the head as I tried. I went into the house, had a beer, and thought about how to get that thing loosened. It came to me: An impact screwdriver! Once that arrived, it was simply a matter of a few blows with the mallet, a few more, a couple more for good measure, and the uncooperative screw was beaten into submission, first barely turning but with each blow going a bit further until I was able to remove it with a normal screwdriver. The intermediate shaft drive was off and the new one on! For good measure, new screws holding the drive were ordered and installed, too.

Once that arrived, it was simply a matter of a few blows with the mallet, a few more, a couple more for good measure, and the uncooperative screw was beaten into submission, first barely turning but with each blow going a bit further until I was able to remove it with a normal screwdriver. The intermediate shaft drive was off and the new one on! For good measure, new screws holding the drive were ordered and installed, too. To get to the main pulley the main crank nut had to be removed. Simple concept but considering it’s torqued to more than 300 ft/lbs…. I puzzled on that for a while, since my electric impact wrench wasn’t strong enough. Talked to a few friends, thus further delaying progress.

To get to the main pulley the main crank nut had to be removed. Simple concept but considering it’s torqued to more than 300 ft/lbs…. I puzzled on that for a while, since my electric impact wrench wasn’t strong enough. Talked to a few friends, thus further delaying progress.

Then main pulley had to be removed and that required a puller.

Then main pulley had to be removed and that required a puller.

The rest of the front cover removal from the old motor and re-installation on the new one went smoothly.

The rest of the front cover removal from the old motor and re-installation on the new one went smoothly.

Next came the oil pump. Wait. Where is the new oil pump? Did I order one? How could I forget that? Couldn’t find one so I searched the invoices for the various parts I ordered. None included an oil pump, so that needed to be ordered. Another delay. While waiting I took the pressure relief valve off the old engine and put it on the new.

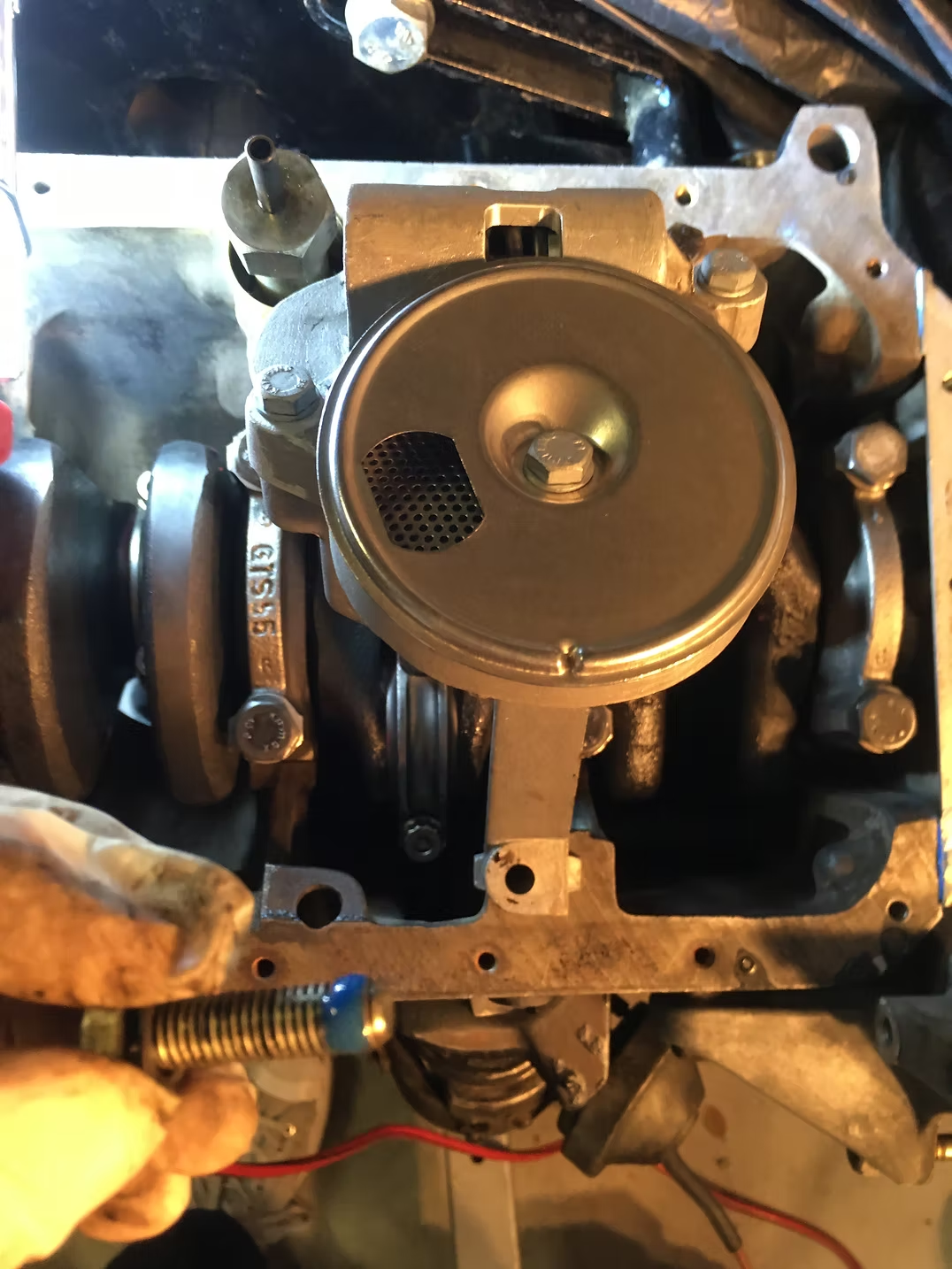

Next came the oil pump. Wait. Where is the new oil pump? Did I order one? How could I forget that? Couldn’t find one so I searched the invoices for the various parts I ordered. None included an oil pump, so that needed to be ordered. Another delay. While waiting I took the pressure relief valve off the old engine and put it on the new. Once the oil pump was in hand, I mounted it on the underside of the block. First a test fit, with the drive and then locktite on the bolts. But, since I never worked on an M20 before I didn’t know how the pump (and distributor) was driven. Hence my introduction to the intermediate shaft and the drive off the belt. Some momentum was building, after all the delays, but it was still over a month since the last update here.

Once the oil pump was in hand, I mounted it on the underside of the block. First a test fit, with the drive and then locktite on the bolts. But, since I never worked on an M20 before I didn’t know how the pump (and distributor) was driven. Hence my introduction to the intermediate shaft and the drive off the belt. Some momentum was building, after all the delays, but it was still over a month since the last update here.

The distributor went in.

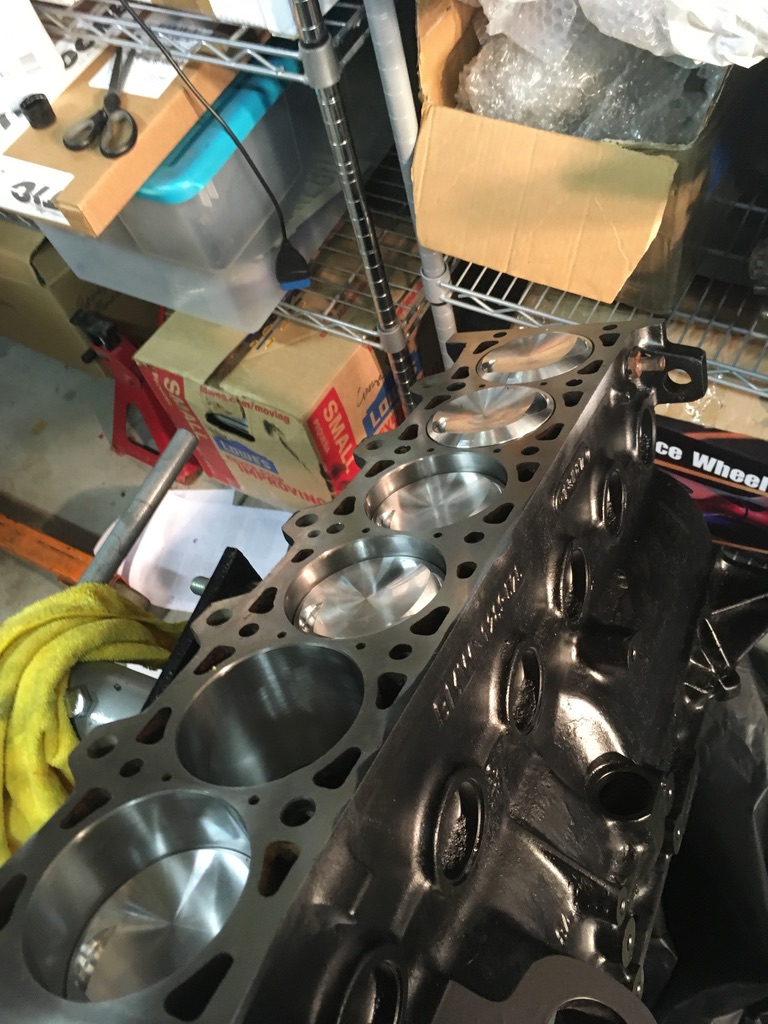

The distributor went in. The head gasket on the block. The head gasket itself is unusual, a metal one that had to be custom made because of the boring out of the block.

The head gasket on the block. The head gasket itself is unusual, a metal one that had to be custom made because of the boring out of the block. The head on that (thanks Frank for the help).

The head on that (thanks Frank for the help).

But, wait, where are the washers for the head bolts? Nowhere – not ordered. Another delay. Calls to the local BMW dealers showed none in Northern California, so another parts order and another delay.

But, wait, where are the washers for the head bolts? Nowhere – not ordered. Another delay. Calls to the local BMW dealers showed none in Northern California, so another parts order and another delay.

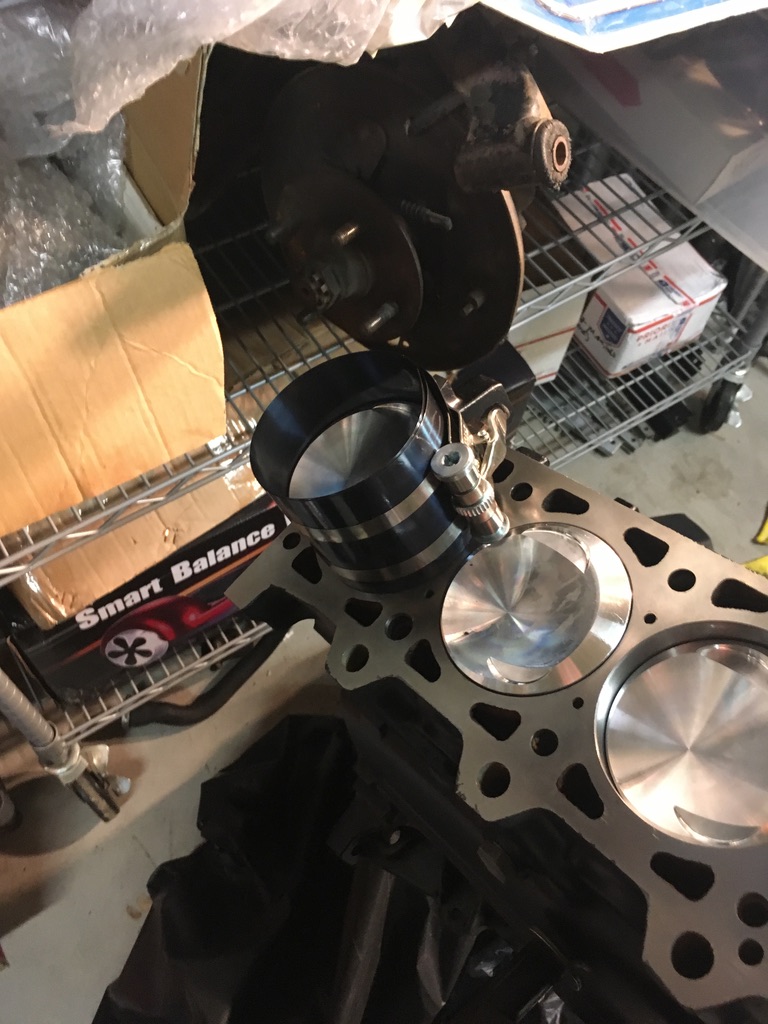

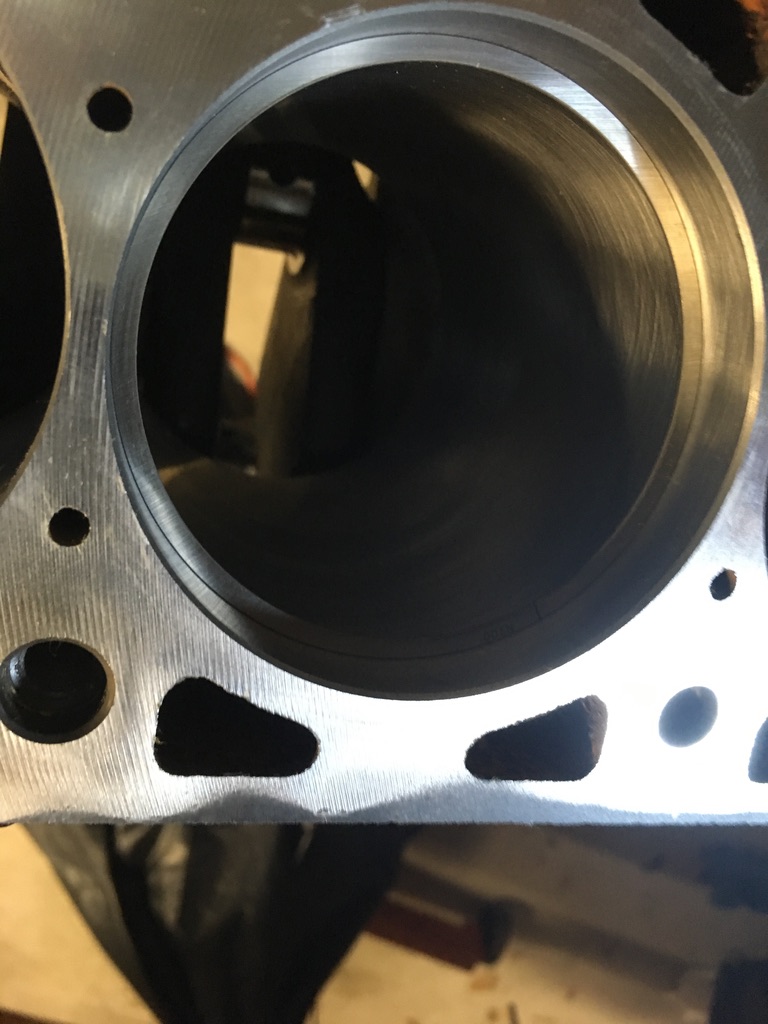

Then, on goes the ring compressor.

Then, on goes the ring compressor. And placed in the block (with rod bearing installed and assembly lube applied. Also, make sure the crank journal for that cylinder is at the bottom of its stroke, so the con rod doesn’t ding it (don’t ask me how I learned that lesson!).

And placed in the block (with rod bearing installed and assembly lube applied. Also, make sure the crank journal for that cylinder is at the bottom of its stroke, so the con rod doesn’t ding it (don’t ask me how I learned that lesson!).

And placed in the block (with rod bearing installed and assembly lube applied. Also, make sure the crank journal for that cylinder is at the bottom of its stroke, so the con rod doesn’t ding it (don’t ask me how I learned that lesson!).

And placed in the block (with rod bearing installed and assembly lube applied. Also, make sure the crank journal for that cylinder is at the bottom of its stroke, so the con rod doesn’t ding it (don’t ask me how I learned that lesson!). One at a time.

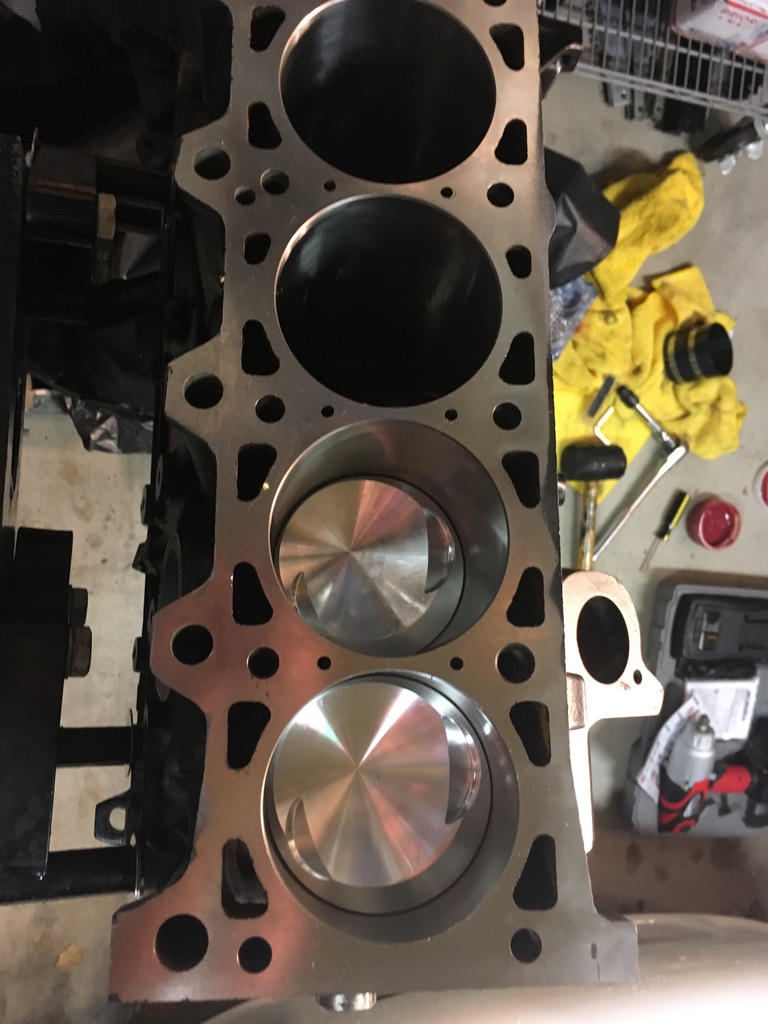

One at a time. Eventually, all six are in.

Eventually, all six are in. Torque the rod bolts.

Torque the rod bolts.

And if you’re lucky, it still turns.

And if you’re lucky, it still turns.

Then I tried to figure out which way the end caps went (internet research helped as it wasn’t obvious from trying to fit them).

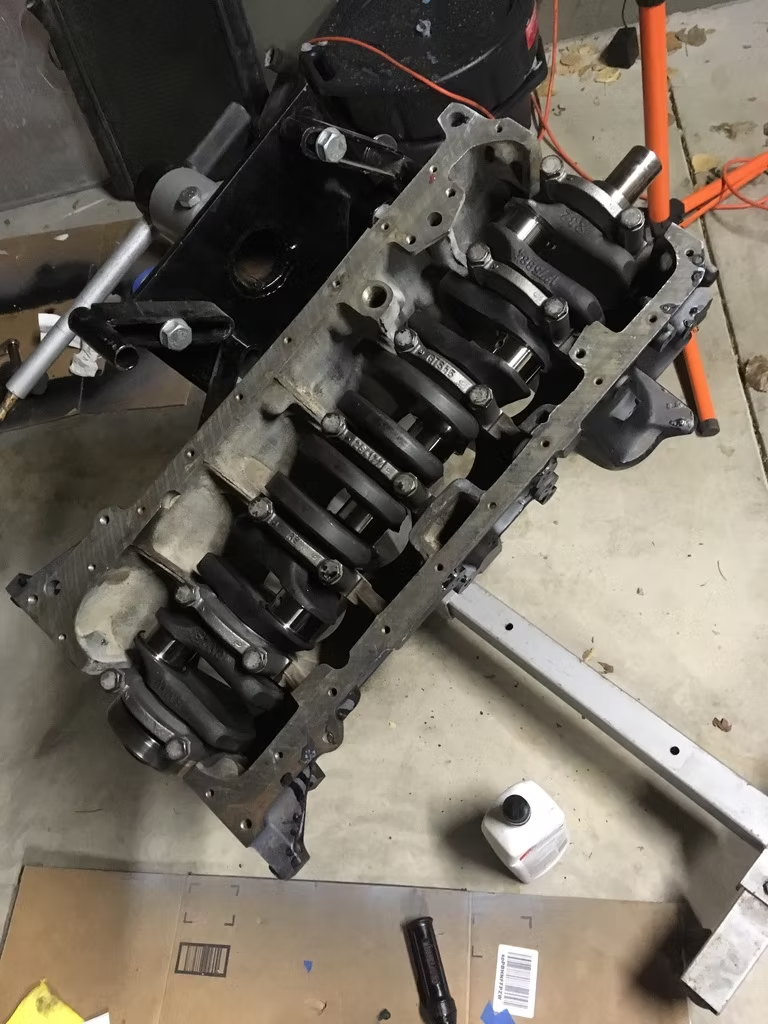

Then I tried to figure out which way the end caps went (internet research helped as it wasn’t obvious from trying to fit them). With the order and orientation of the end caps clarified, it was time to install the rod bearings in the block.

With the order and orientation of the end caps clarified, it was time to install the rod bearings in the block.

And the end caps.

And the end caps.

Then it was time for the turbo diesel crank.

Then it was time for the turbo diesel crank.

Gently place the crank in the block.

Gently place the crank in the block.

And install the end caps with bearings.

And install the end caps with bearings.

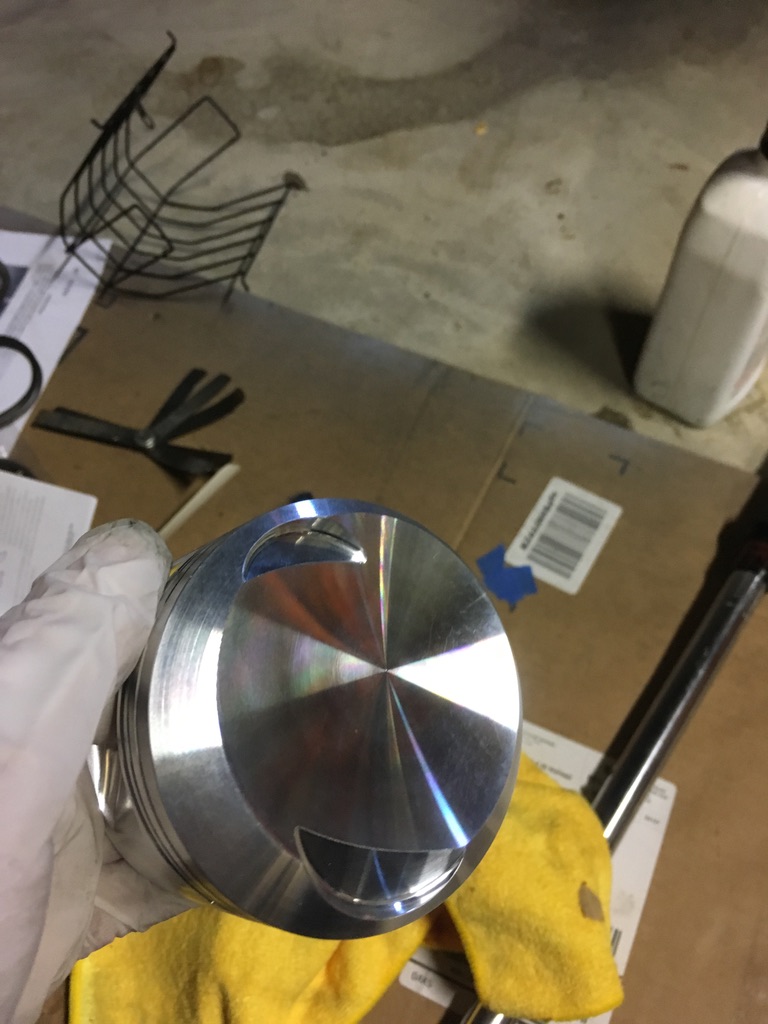

And install them on the pistons.

And install them on the pistons.

Then attach the rods to the pistons. The hardest part being, without the right tool, installing the wrist-pin retaining clips.

Then attach the rods to the pistons. The hardest part being, without the right tool, installing the wrist-pin retaining clips.

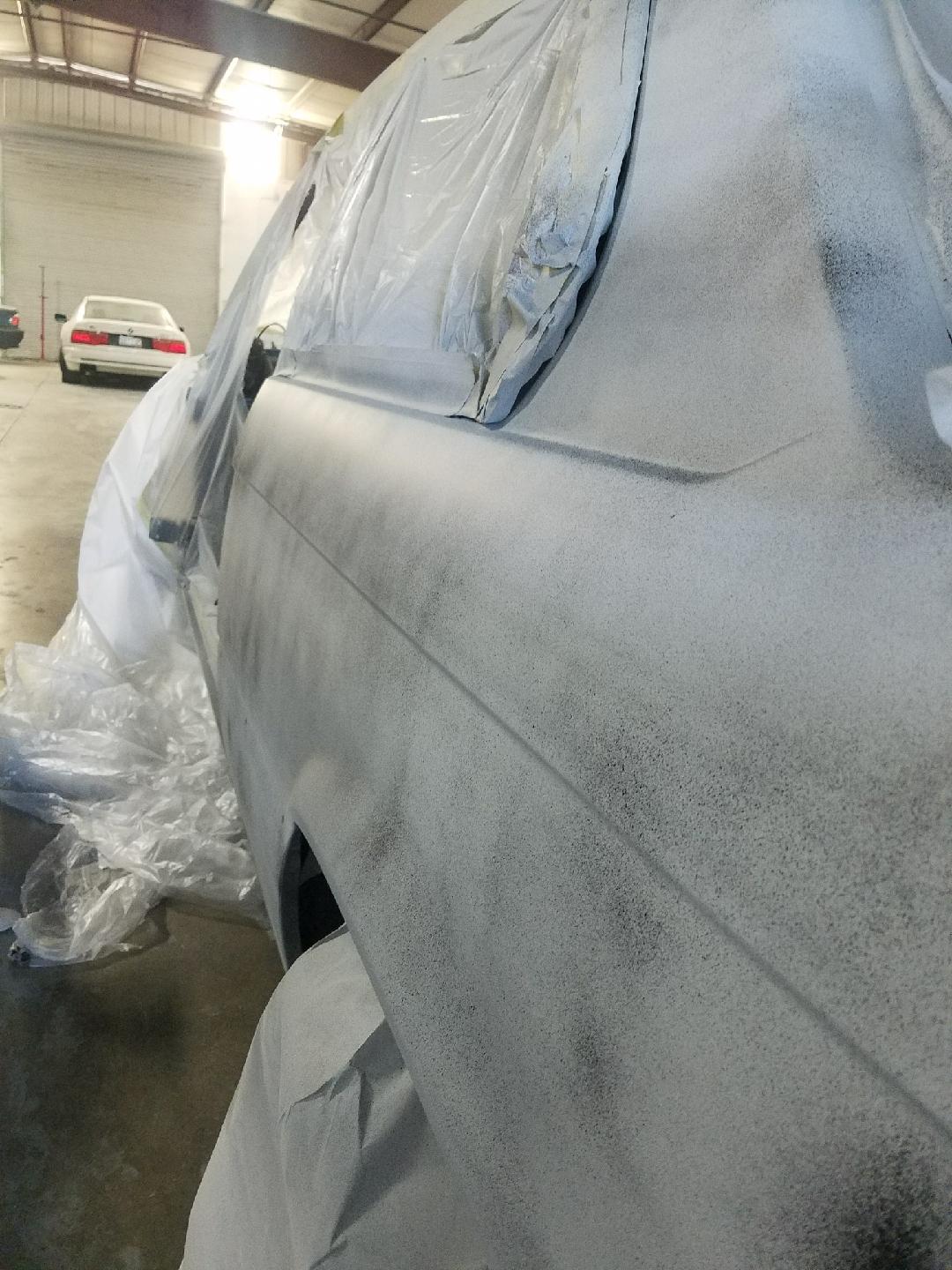

And then finally the shell, including the engine compartment, got painted.

And then finally the shell, including the engine compartment, got painted.

Next? The “new” dash and the glass will be installed and the body re-assembled. And with any luck, “tomorrow” may eventually come and the motor parts will be ready for me to begin assembling the motor.

Next? The “new” dash and the glass will be installed and the body re-assembled. And with any luck, “tomorrow” may eventually come and the motor parts will be ready for me to begin assembling the motor.

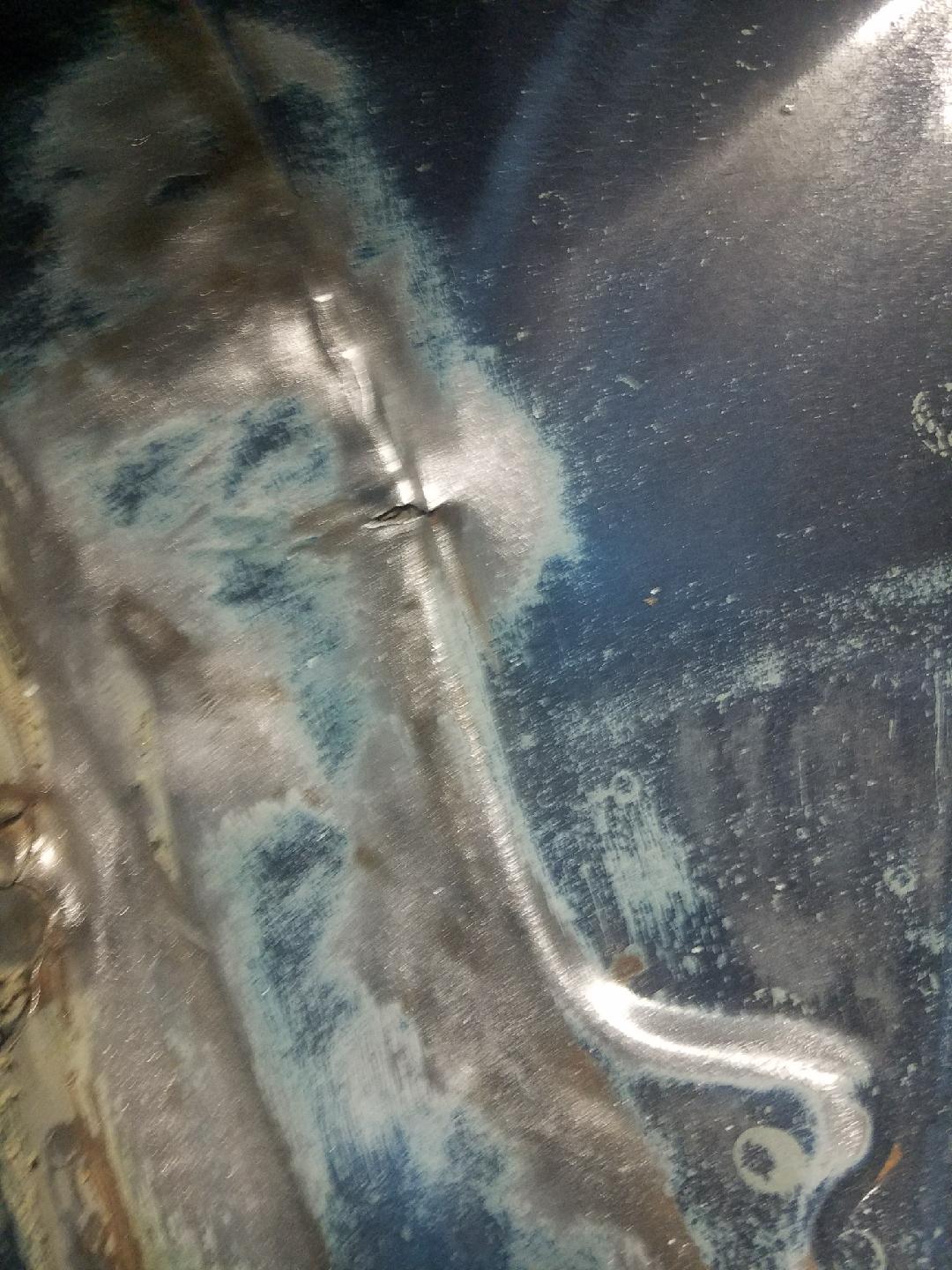

And welded up.

And welded up.

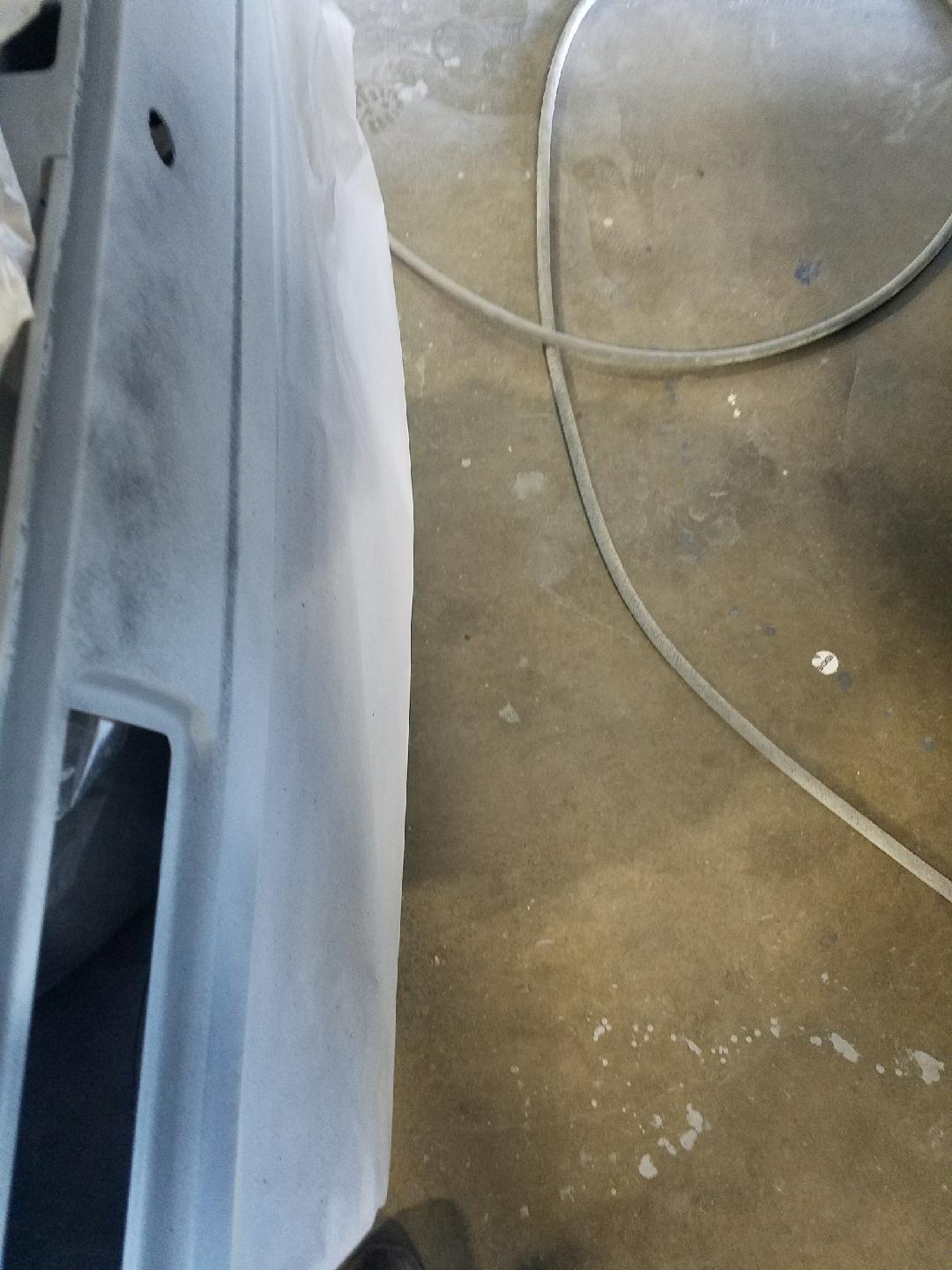

The front fender gets cleaned up, including plugging the holes for the USA sidemarker lights.

The front fender gets cleaned up, including plugging the holes for the USA sidemarker lights. Waves a long the rear fenders and roof are smoothed out.

Waves a long the rear fenders and roof are smoothed out.

And the air dam gets cleaned up as well.

And the air dam gets cleaned up as well. Next up: finish prepping for paint, prime it, and then paint it. The body work has good momentum, I sure hope the motor will start moving along.

Next up: finish prepping for paint, prime it, and then paint it. The body work has good momentum, I sure hope the motor will start moving along.